Chemical textile fiber dehydrator

A textile fiber and dehydrator technology, applied in dryers, non-progressive dryers, drying solid materials, etc., can solve the problems of slow chemical fibers, being piled up to the bottom, affecting the efficiency of chemical fiber processing, etc., to improve effect of chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

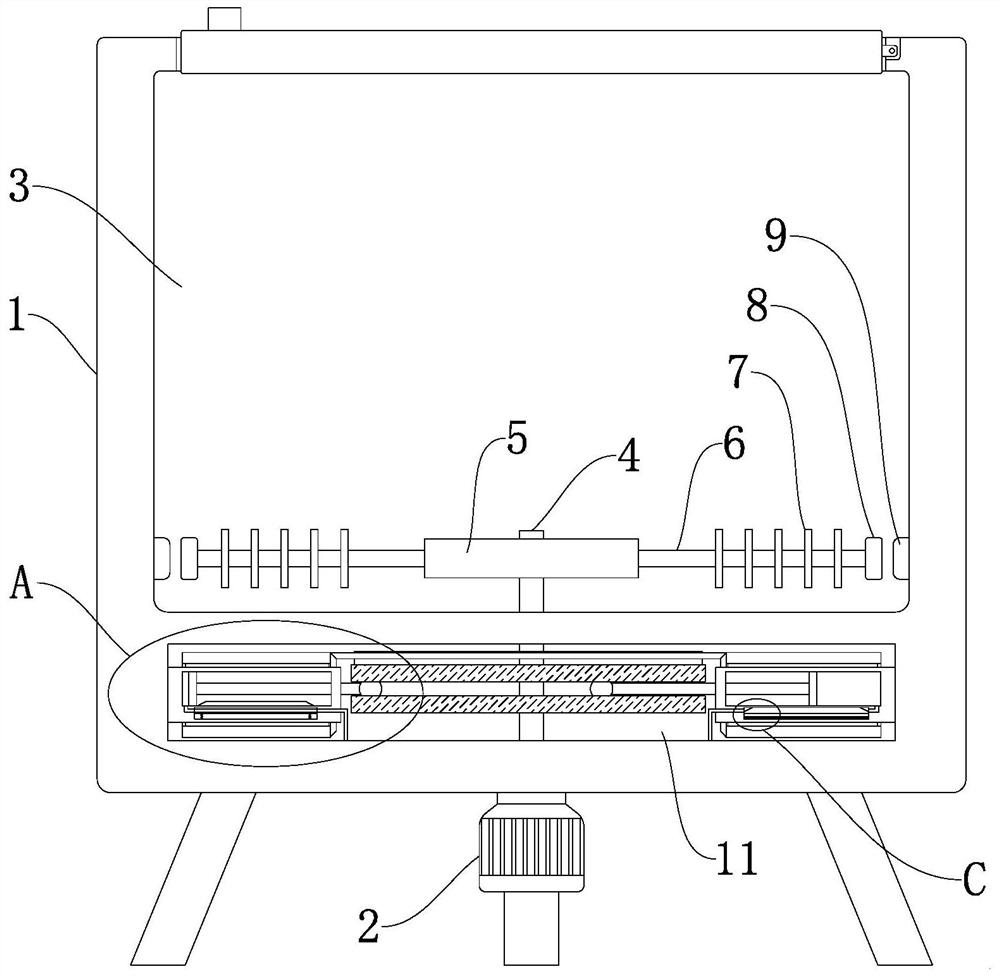

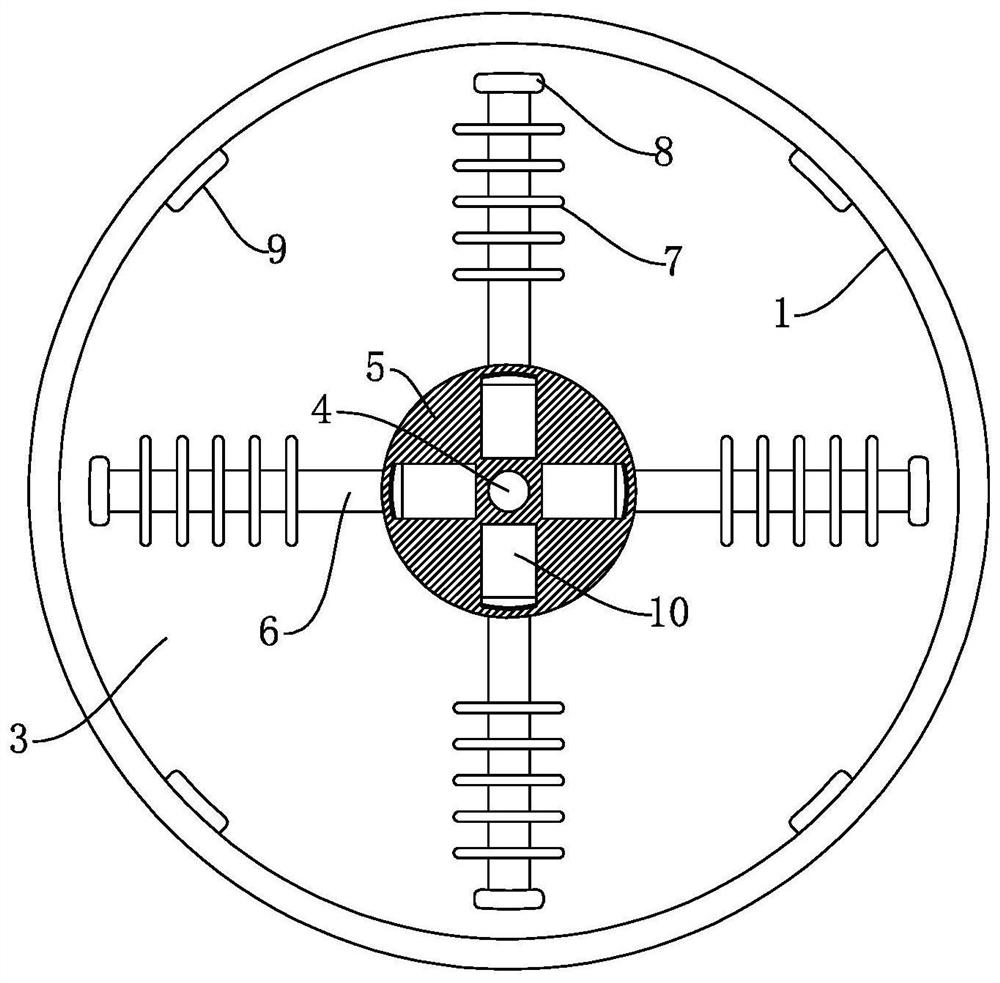

[0041] As an embodiment of the present invention, refer to figure 2 , the magnetic force assembly includes the first permanent magnets 8 that are arranged on the other ends of the plurality of slide bars 6 respectively, and the inner bottom of the dehydration chamber 3 is provided with a plurality of second permanent magnets 9 at equal intervals around the circumference, and the plurality of first permanent magnets 8 are connected to the corresponding The polarities of the opposite sides of the adjacent second permanent magnets 9 are set to be the same.

[0042] Only when the polarities of the first permanent magnet 8 and the second permanent magnet 9 close to each other are set the same, and mutual repulsion occurs between the two, the second permanent magnet 9 can be used to promote the first permanent magnet 8 to move, so that the slide bar 6 Move towards the inner bottom of the chute 10.

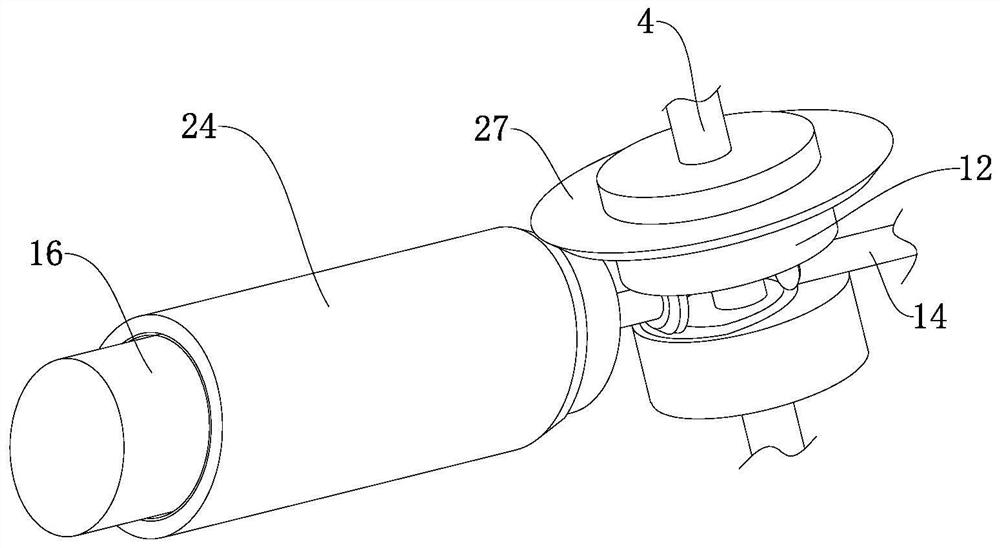

[0043] As an embodiment of the present invention, refer to Figure 3-8 , the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com