Efficient mine wastewater treatment equipment

A technology for mine wastewater and treatment equipment, which is applied in mining wastewater treatment, multi-stage water treatment, biological water/sewage treatment, etc., can solve the problems of insufficient contact reaction of mine wastewater treatment agents and low treatment efficiency, and achieve cost savings and Time, improve processing efficiency, and speed up the effect of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

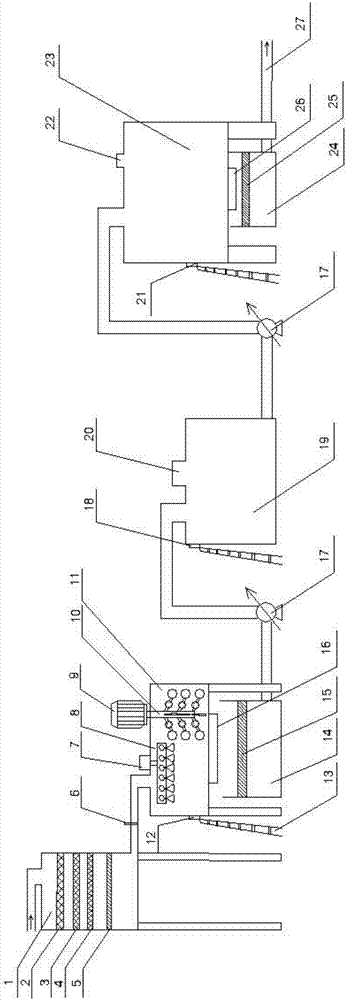

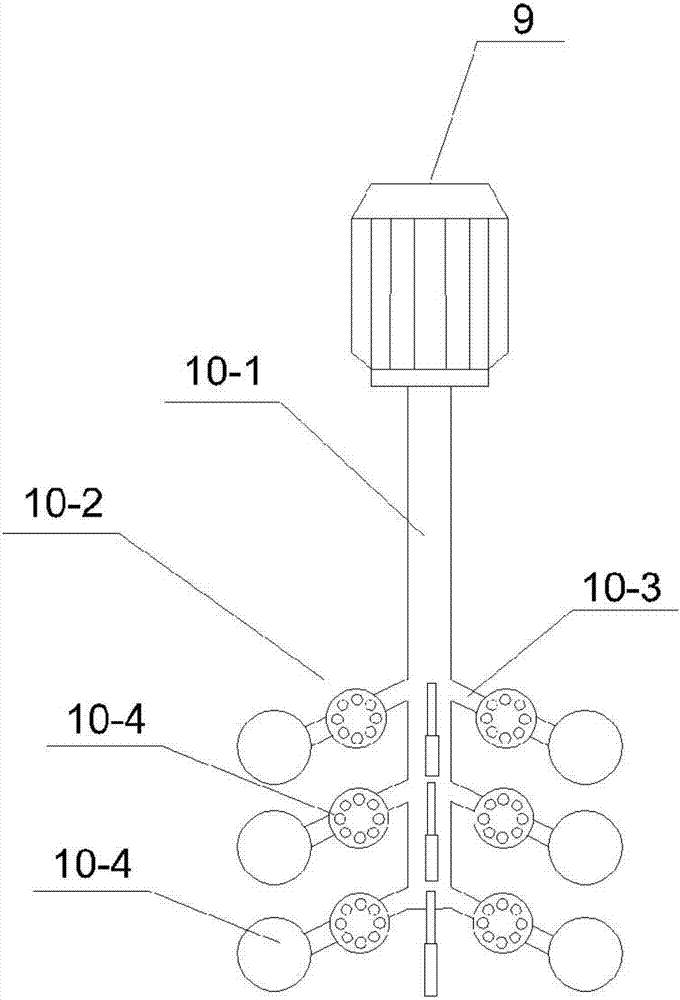

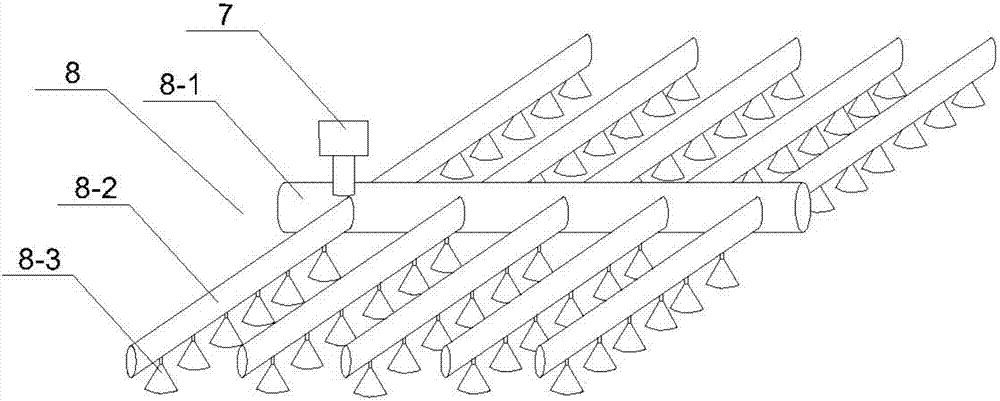

[0028] Such as figure 1 and 2 As shown, the present embodiment provides a kind of high-efficiency mine wastewater treatment equipment, including multi-stage sedimentation filter tank 1, heavy metal ion treatment tank 11, sedimentation tank one 14, acid-base neutralization tank 19, biological flocculation tank 23 and sedimentation tank two 24. The heavy metal ion treatment tank 11 is provided with an agitator 10 powered by a motor 9, and the agitator 10 includes a main agitating shaft 10-1 and three groups of A stirring assembly 10-2, the stirring assembly 10-2 includes a plurality of stirring rods 10-3 uniformly distributed on the main stirring shaft 10-1 according to the circumference, and a piece of round cake is arranged in the middle of each stirring rod 10-3 A circular cake-shaped solid stirring blade 10-5 is arranged on the top of the stirring rod 10-3, and the top of the heavy metal ion treatment pool 11 is provided with a dosing port 7, and the dosing port 7 passes th...

Embodiment 2

[0037] Such as Figure 1-3 As shown, the present embodiment provides a kind of high-efficiency mine wastewater treatment equipment, including multi-stage sedimentation filter tank 1, heavy metal ion treatment tank 11, sedimentation tank one 14, acid-base neutralization tank 19, biological flocculation tank 23 and sedimentation tank two 24. The heavy metal ion treatment tank 11 is provided with an agitator 10 powered by a motor 9, and the agitator 10 includes a main agitating shaft 10-1 and three groups of A stirring assembly 10-2, the stirring assembly 10-2 includes a plurality of stirring rods 10-3 uniformly distributed on the main stirring shaft 10-1 according to the circumference, and a piece of round cake is arranged in the middle of each stirring rod 10-3 A circular cake-shaped solid stirring blade 10-5 is arranged on the top of the stirring rod 10-3, and the top of the heavy metal ion treatment pool 11 is provided with a dosing port 7, and the dosing port 7 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com