An intelligent wrapping machine

A cloth-wrapping and special-purpose machine technology, which is applied in the field of intelligent cloth-wrapping special machines, can solve problems such as difficulty in maintaining accuracy, inconvenience in industrial production, and failure to reach the specified position, and achieve the effects of reducing force fluctuations, saving glue, and facilitating observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

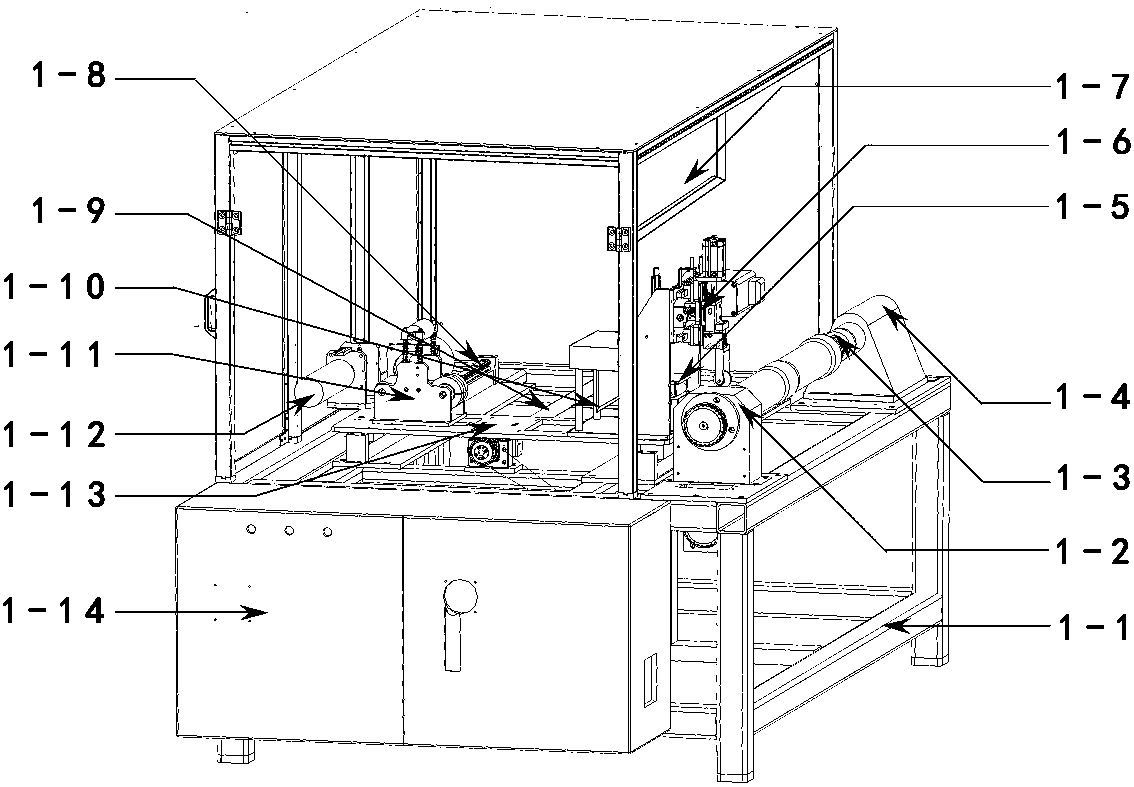

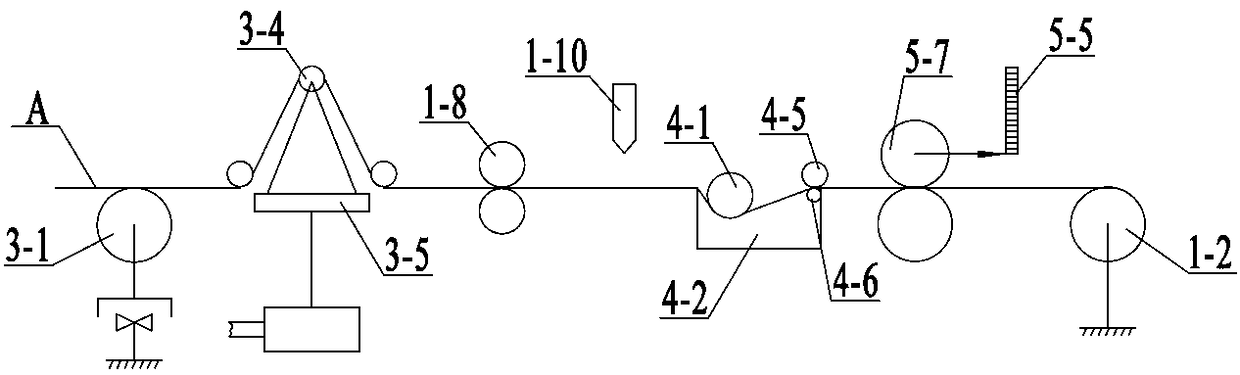

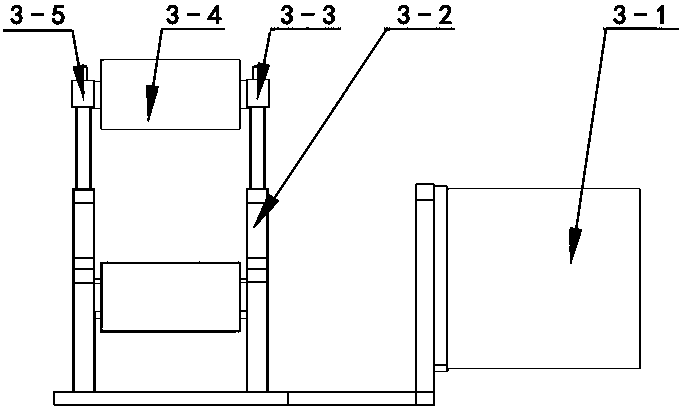

[0022] Such as figure 1 , 2 , 3, 4, 5, and 6, the present invention includes a frame 1-1, a lead screw 1-9 arranged in the middle of the frame 1-1, a motor, a feeding mechanism, and a control device for closed-loop control tension , a gluing mechanism, a monitoring device for real-time online monitoring of the diameter of the wrapped cloth, a cutting knife 1-10 connected to the output end of the cylinder set on the frame 1-1, a material receiving mechanism, and a device for regulating the motor and the material receiving mechanism The control module and human-computer interaction panel 1-7; the feeding mechanism, control device, cutting knife 1-10, gluing mechanism, and monitoring device are sequentially arranged on the swing plate 1-13 from left to right and follow the swing plate 1 -13 moves, the swinging plate 1-13 is set on the lead screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com