Method of manufacturing coarse cereal bread by using bread maker

A bread and mechanism technology, which is applied in toasting devices, applications, household appliances, etc., can solve the problems of insufficient, unreasonable formula, and low quality of bread, and achieve the effect of normal volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

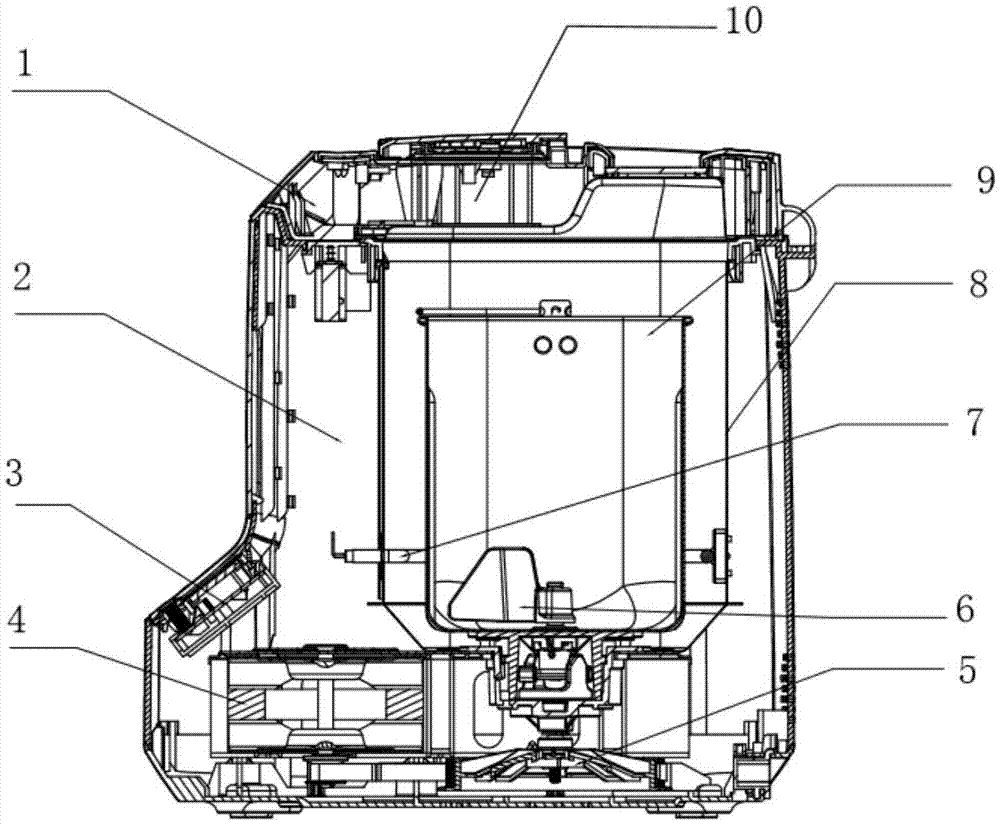

[0047] In each embodiment, a bread machine is used to make multigrain bread. The structural diagram of the bread machine is shown in Figure 2, including a top cover 1, an outer shell 2, a control circuit board 3, a motor 4, a transmission mechanism 5, a stirring mechanism 6, a heating element 7, an automatic feeding device 8 and a bread bucket 9. The heating element 7 is a heat pipe for heating the bread barrel 9 . The upper cover 1 covers the outer casing 2, and the outer casing 2 is provided with a bread bucket 9 from the inside to the outside in turn. The bread bucket is provided with a stirring mechanism 6 connected to the motor 4, and two bread buckets 9 and the upper cover 1 are provided. Automatic feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com