Inductive percussion instrument based on wood grain style printing and conductive ink

A technology for conductive ink and percussion instruments, which is applied to electroacoustic musical instruments, inks, instruments, etc., can solve the problems of high probability of damage to children, high process complexity, large number of parts, etc., and achieves low cost, simple process implementation, and not easy to fall off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the drawings and embodiments.

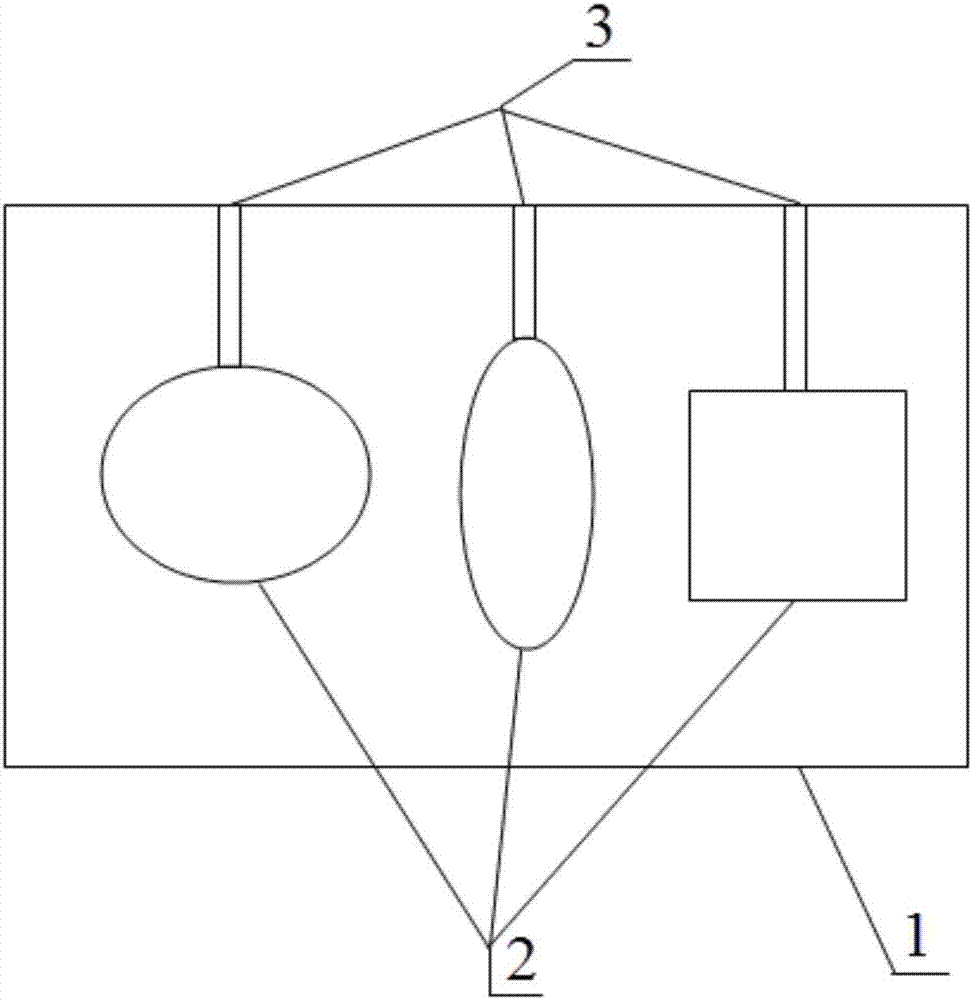

[0030] The present invention provides an induction percussion instrument based on wood grain printing and conductive ink, including a percussion panel 1, with reference to figure 1 with figure 2 , The upper surface of the beating panel 1 is coated with conductive ink blocks 2, and the lower surface of the beating panel 1 is provided with a sounding horn 4 powered by the power module 5, and the sounding horn 4 is connected to the beating panel through the conductive ink line 3 The conductive ink block 2 on the upper surface is connected.

[0031] The upper surface of the beating panel is provided with more than two conductive ink blocks, and the lower surface of the beating panel is provided with the same number of sounding horns. Each conductive ink block is connected to a sounding horn through conductive ink lines, and different conductive ink lines There is no overlap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com