Stove-connecting kang heating and hot water system for burning biomass fuel and using method of stove-connecting kang heating and hot water system

A biomass fuel and hot water system technology, applied in residential hot water supply systems, heating systems, heating methods, etc., can solve problems such as excessive smoke, insufficient fuel combustion, pollution, etc., and achieve sufficient ventilation in the furnace and improve combustion. Efficiency, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

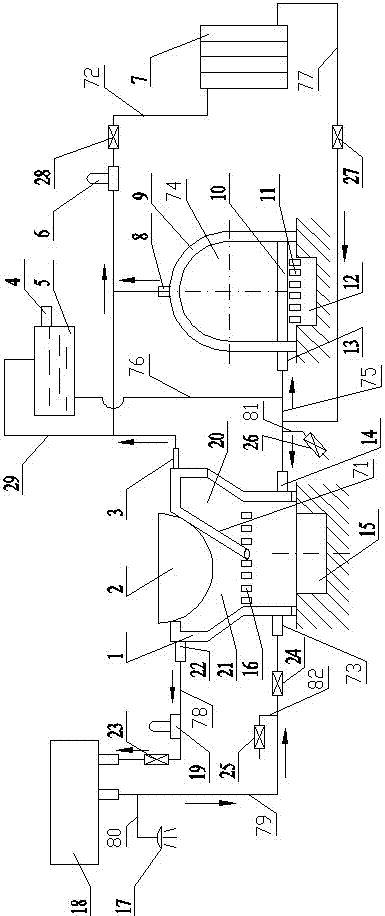

[0033] Such as figure 1As shown, the stove-connected kang heating and hot water system for burning biomass fuel of the present invention includes an expansion tank 5, a kitchen stove, a kang stove, a radiator 7 for room heating, and an arched water jacket for heating in a kang cave. 9 and a shower device; the expansion tank 5 is located at the highest point in the system;

[0034] The kitchen stove includes a kitchen stove water jacket 1 as a furnace wall. The kitchen stove water jacket 1 is located outside and adjacent to the building exterior wall; The first fire grate 16, the kitchen stove water jacket 1 above the first fire grate 16 is connected downward with a partition water jacket 71, and the partition water jacket 71 divides the inner space of the kitchen stove water jacket 1 into a cooking furnace 21 and a shower hearth 20, the top of the cooking hearth 21 has an opening for erecting cooking utensils 2 (such as a cauldron), and the ground below the first fire grate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com