Rubber air spring and application thereof

A rubber air spring, air intake technology, applied in springs, springs/shock absorbers, gas shock absorbers, etc., can solve the problems of weak internal pressure resistance, easy friction damage, low bearing capacity, etc. The effect of stable vibration efficiency, large bending angle and high working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

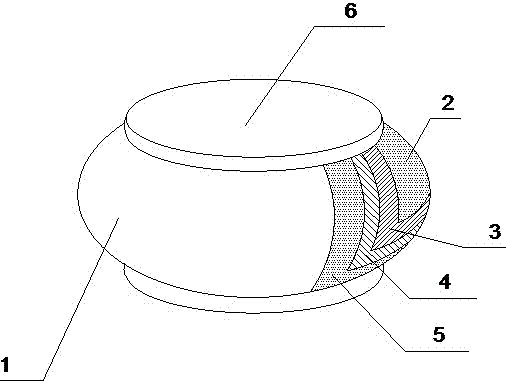

[0026] see figure 1 , a rubber air spring, including a rubber air spring main body 1, the rubber air spring main body 1 includes a lantern-shaped structure 8, and the rubber air spring main body 1 includes an outer rubber layer 2, a first layer from outside to inside The ply layer 3 and the second ply layer 4; the outermost layer of the rubber air spring main body 1 is a layer of calendered rubber outer layer glue, the innermost layer of the rubber air spring main body 1 is a layer of calendered rubber lining, and the middle part of the rubber air spring main body 1 The skeleton layer is reinforced for two layers of cords, and the structure is firm; preferably, the top and bottom of the rubber air spring main body 1 are fixedly connected with sealing end plates 6 , and the top and bottom of the rubber air spring main body 1 are sealed by the sealing end plates 6 .

Embodiment 2

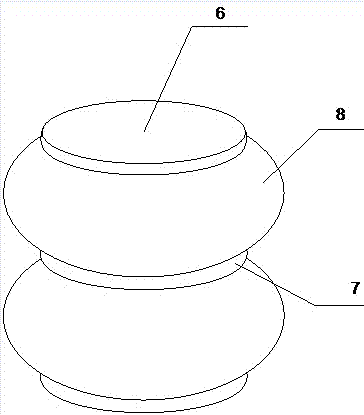

[0028] see figure 2 , a rubber air spring, including a rubber air spring main body 1, the rubber air spring main body 1 includes a plurality of lantern-shaped structures 8, and annular grooves 7 are arranged between adjacent lantern-shaped structures 8, and the annular grooves 7 is provided with a waist ring, the waist ring is closely attached to the wall of the annular groove 7, and the waist ring is molded by steel welding parts or rubber-coated steel wires; the rubber air spring main body 1 includes an outer rubber layer from outside to inside 2. The first ply layer 3 and the second ply layer 4; the outermost layer of the rubber air spring main body 1 is a layer of calendered rubber outer layer glue, and the innermost layer of the rubber air spring main body 1 is a layer of calendered rubber lining. The middle part of the air spring main body 1 is a two-layer ply reinforced skeleton layer, and the structure is firm; preferably, the top and bottom of the rubber air spring m...

Embodiment 3

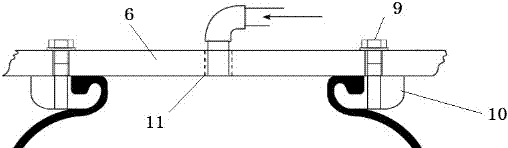

[0030] see image 3 , a rubber air spring, comprising a rubber air spring main body 1, the top and bottom of the rubber air spring main body 1 are fixedly connected with a sealing end plate 6, and the top and bottom of the rubber air spring main body 1 are sealed by the sealing end plate 6; The lower end of the sealing end plate 6 is fixedly connected with a flange 10 through the cooperation of several bolts 9 and nuts. The flange 10 is a flange ring, and the flange 10 is made of aluminum or steel. The sealing end plate 6 is provided with an air inlet 11. The source enters the interior of the rubber air spring through the air intake hole. The air intake hole 11 is provided with a one-way air intake valve. The inner side of the flange 10 is provided with an annular J-shaped groove. The end of the rubber air spring main body 1 Embedded and connected in the J-shaped groove, the end of the rubber air spring main body 1 is attached to the wall of the J-shaped groove, and the bolt 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com