Shield tunneling machine cutter capable of being quickly replaced

A shield machine and cutting tool technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems that affect work efficiency, serious tool wear, and dangers caused by manual excavation of tunnels, etc., and achieve the effect of fixed tools and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

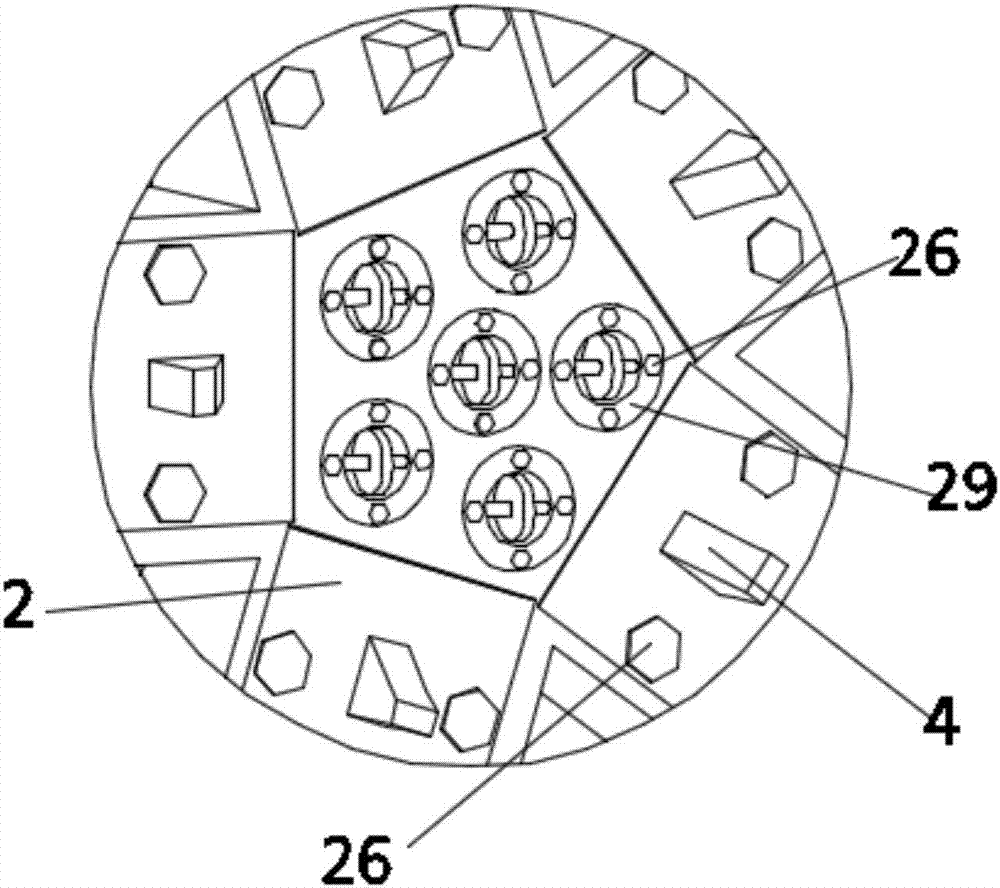

[0028] see Figure 1-6 , the present invention provides a technical solution: a quick-change shield machine tool, including a cutter head 1, the cutter head 1 is fixedly connected to a plurality of tool holders 2 in the circumferential direction, and the tool holder 2 is provided with a tool hole 3, a first cutter 4 is movably connected in the cutter hole 3, and the first cutter 4 includes a handle 41 and a cutter head 42, and the cutter head 42 and the handle 41 are fixedly connected, and the bottom of the handle 41 There are first grooves 7 on both sides, and a fixed plate 8 is movably connected in the first grooves 7. After the first cutter 4 is inserted into the cutter hole 3, the first groove 7 is just located in the first cavity 9 , and then make the fixing plate 8 snap into the first groove 7, the first tool 4 can be fixed, the fixing plate 8 is slidably connected in the first cavity 9, and the bottom surface of one end of the fixing plate 8 is fixedly connected with te...

Embodiment 2

[0031] see Figure 1-8, the present invention provides a technical solution: a quick-change shield machine tool, including a cutter head 1, the cutter head 1 is fixedly connected to a plurality of tool holders 2 in the circumferential direction, and the tool holder 2 is provided with a tool hole 3, a first cutter 4 is movably connected in the cutter hole 3, and the first cutter 4 includes a handle 41 and a cutter head 42, and both sides of the bottom of the handle 41 are provided with first grooves 7, so The first groove 7 is movably connected with a fixed plate 8. After the first tool 4 is inserted into the tool hole 3, the first groove 7 is just located in the first cavity 9, and then the fixed plate 8 is snapped into the first groove. 7, the first tool 4 can be fixed, the fixed plate 8 is slidably connected in the first cavity 9, the bottom surface of one end of the fixed plate 8 is fixedly connected with teeth 10, and the teeth 10 are connected with the first gear 11, the...

Embodiment 3

[0034] see Figure 9 , the present invention provides a technical solution: a quick-change cutter for shield machine, including a first cutter 4, the first cutter 4 includes a handle 41 and a cutter head 42, and the handle 41 is provided with a through hole Slot 32, the cutter head 42 is movably connected in the through groove 32, the bottom of the cutter head 42 is fixedly connected to the limit block 33, the limit block 33 is stuck in the through groove 32, and the limit block 33 is movably connected and fixed Block 34, the fixed block 34 and the limit block 33 are fixed on the handle 41 by bolts 26. After the first tool 4 is removed from the tool holder 2, the bolt 26 at the bottom of the handle 41 is unscrewed to remove the fixed Block 34 just can take out cutter head 42 in the through groove 32 of handle of a knife 41 then, and this is in order to prevent that cutter head 42 is damaged and handle of a knife 41 is intact in order to prevent first cutter 4 from occurring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com