High-temperature melting electrostatic spinning auxetic filament fiber preparing device and method and application thereof

An electrospinning method and filament fiber technology, which is applied in the field of industrial auxetic structural materials, can solve the problems of unstable forming, fiber crossing, poor adhesion, and high plasticity, and achieve good mechanical properties and broad market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

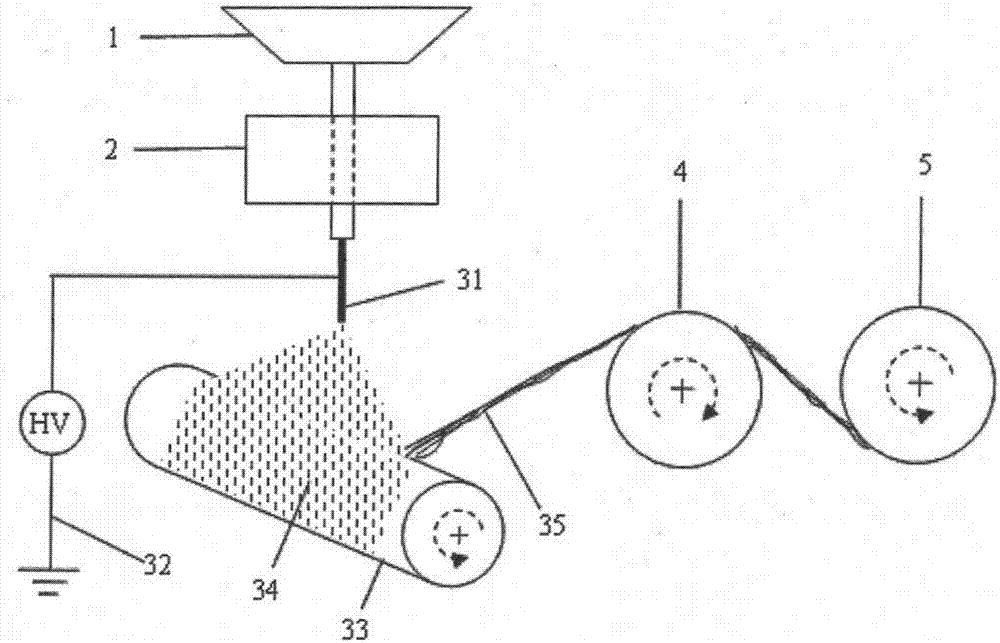

Method used

Image

Examples

Embodiment 1

[0031]Using carbon fiber single-needle melt electrospinning and a collection device with a concave hexagonal honeycomb structure, the nonwovens produced are as follows: figure 2 shown.

Embodiment 2

[0033] Using carbon fiber multi-needle melt electrospinning, using a collection device with a star-shaped network auxetic structure, the nonwovens produced are as follows: image 3 shown.

Embodiment 3

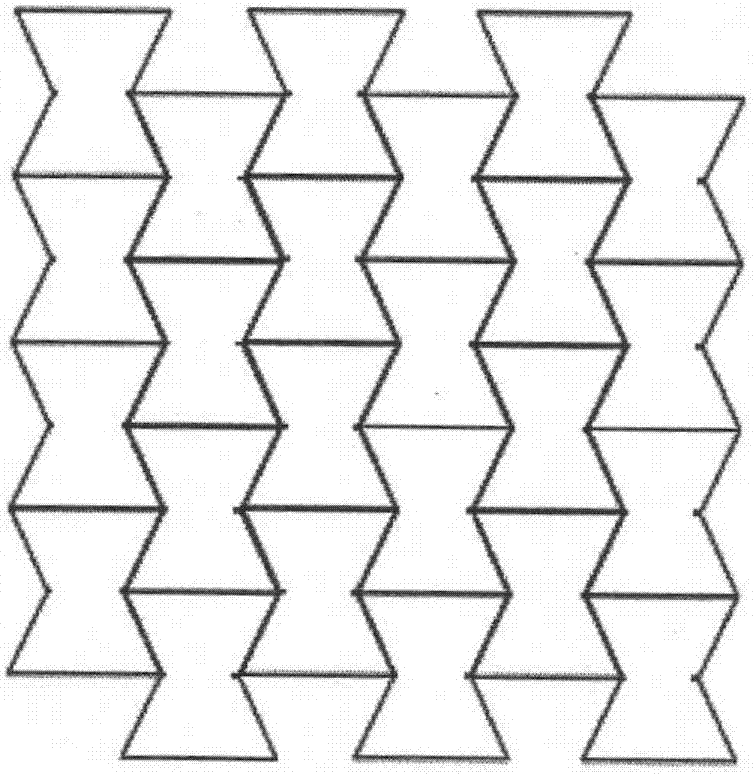

[0035] Using carbon fiber needle-free fusion electrospinning and a collection device with a double-arrow auxetic structure, the nonwovens produced are as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com