Turn-milling combined-type drilling and tapping center

A compound, turning-milling technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of single completion of drilling, milling, tapping, etc., to simplify workpiece clamping, meet production process requirements, and save non-production the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

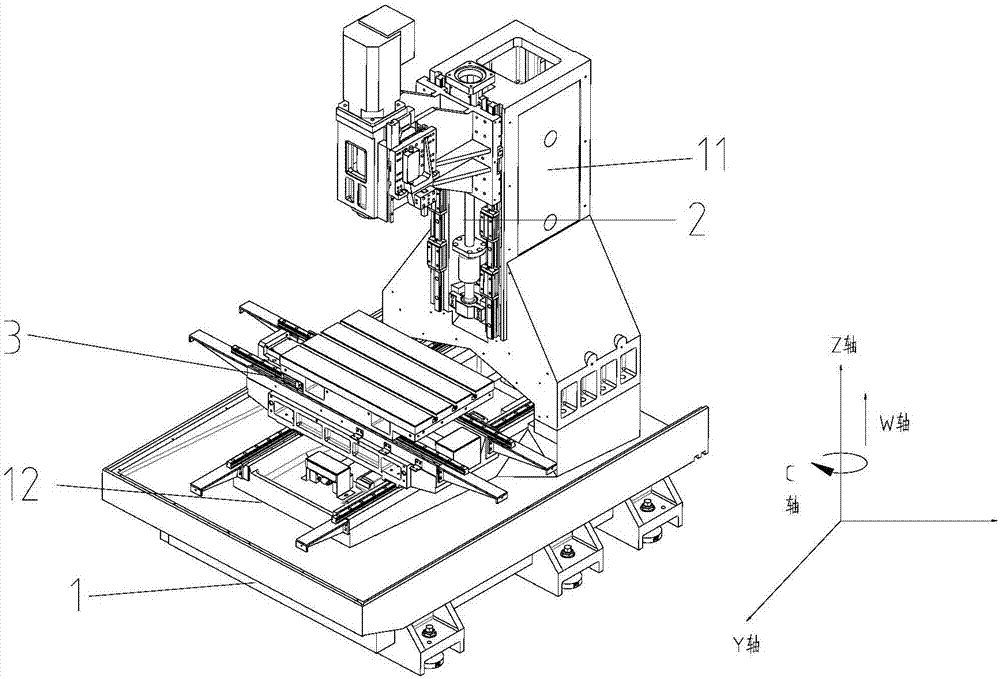

[0017] figure 1 It is a schematic structural diagram of a turning-milling compound drilling and tapping center according to an embodiment. Such as figure 1 As shown, a turning-milling compound drilling and tapping center includes: a milling machine tool 1, a turning head 2 and a turning-milling turntable 3; the turning head 2 is installed on the side of the milling head of the milling machine tool 1; the turning-milling turntable 3 is installed Above the worktable of the milling machine tool 1; the motion axes of the turning-milling compound drilling and tapping center are X axis, Y axis, Z axis, C axis, and W axis, wherein X, Y, and Z axes form a three-dimensional space, and the W axis Parallel to the Z axis, the W axis is the direction axis of the vertical feed movement of the turning head 2, the C axis rotates around the Z axis, and the C axis is the rotation direction axis of the turning and milling turntable 3; when the turning head 2 moves, the turning and milling turnt...

Embodiment 2

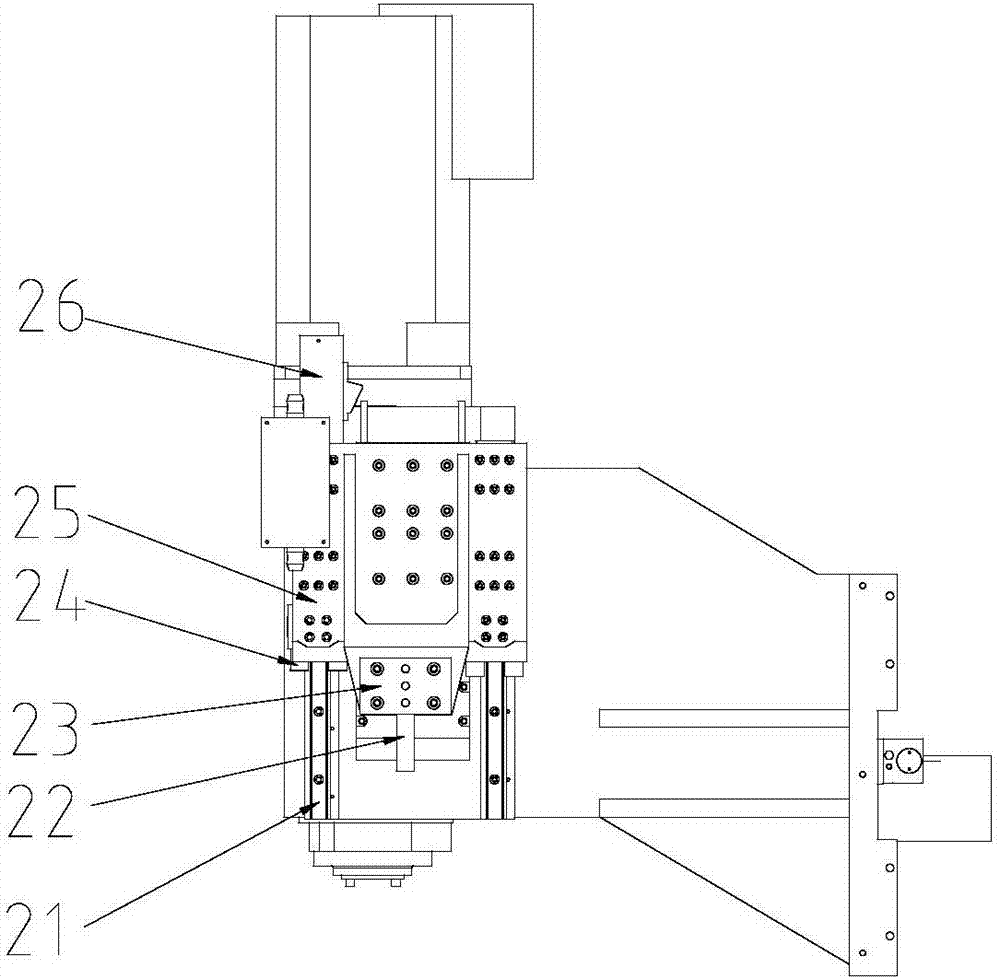

[0021] figure 1 It is a schematic structural diagram of a turning-milling compound drilling and tapping center according to an embodiment. figure 2 It is a schematic structural diagram of the turning head of the turning-milling compound drilling and tapping center of an embodiment. combine figure 1 with figure 2 This embodiment will be described.

[0022] A turning-milling compound drilling and tapping center, comprising: a milling machine tool 1, a turning head 2, and a turning-milling turntable 3; the turning head 2 is installed on the side of the milling head of the milling machine tool 1; the turning-milling turntable 3 is installed on the milling machine tool 1 above the worktable; the movement axes of the turning-milling compound drilling and tapping center are X-axis, Y-axis, Z-axis, C-axis, and W-axis, wherein X, Y, and Z-axes form a three-dimensional space, and W-axis and Z-axis Parallel, the W axis is the direction axis of the vertical feed movement of the turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com