A kind of preparation method of micron silver wire

A technology of silver wire and silver salt, which is applied in the field of micron-scale material preparation, can solve problems such as waste of resources, achieve the effects of fewer processes, improve growth efficiency, and inhibit lateral growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

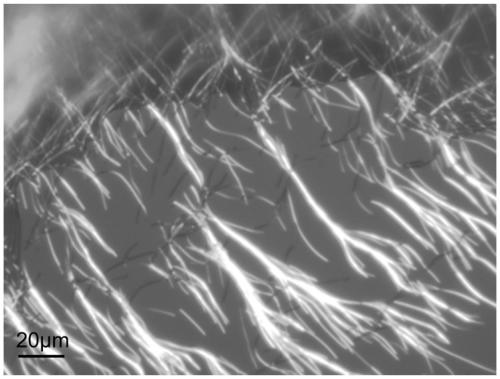

Embodiment 1

[0027] The present embodiment prepares micron silver wire according to the following steps:

[0028] Add 2g of PVP to 100mL of glycerol at a temperature of 80°C to form a glycerol solution of PVP; after cooling the glycerol solution of PVP to room temperature naturally, add 0.4g of silver salt for the first time and mix well; then Heat up to 40°C, add 1mL of 500mmol / L sodium chloride in glycerol and mix well; then continue to heat up to 90°C, add 1mL of 300mmol / L tetrabutylammonium chloride in glycerol, and add 0.4g of silver salt, mix well; then continue to heat up to 160°C, keep the temperature for 30min, then add 0.4g of silver salt for the third time, continue to react at 160°C for 3h; after the obtained reaction solution is cooled, use acetone, alcohol and deionized Settle the water and centrifuge to remove glycerol and PVP, and then dry at 80°C for 10 hours to obtain the target product micron silver wire. Or without drying, the micron silver filaments are preserved and ...

Embodiment 2

[0031] The present embodiment prepares micron silver wire in the same manner as in Example 1, the difference is only that the glycerol solution of 1mL 500mmol / L sodium chloride is replaced with the glycerol solution of 1.5mL 800mmol / L sodium bromide, and all the other conditions are the same. Change.

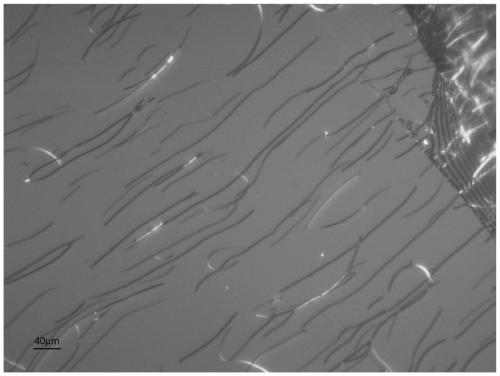

[0032] figure 2 It is an optical microscope picture of the micron silver wire obtained in this embodiment. In the figure, the micron silver wire has a diameter of 3-5 μm and a length of 500-600 μm, with good uniformity of diameter and length, high yield and few silver particles.

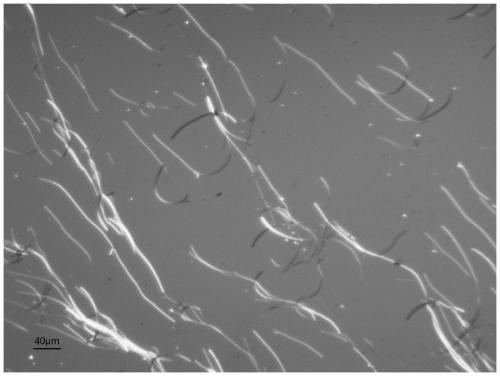

Embodiment 3

[0034] The present embodiment prepares micron silver wire according to the following steps:

[0035] Add 4g of PVP to 100mL of glycerol at a temperature of 80°C to form a glycerol solution of PVP; after cooling the glycerol solution of PVP to room temperature naturally, add 0.4g of silver salt for the first time and mix well; then Heat up to 40°C, add 1mL of 500mmol / L sodium chloride in glycerol and mix well; then continue to heat up to 90°C, add 1mL of 300mmol / L tetrabutylammonium chloride in glycerol, and add 0.4g of silver salt, mix well; then continue to heat up to 160°C, keep the temperature for 30min, then add 0.4g of silver salt for the third time, continue to react at 160°C for 3h; after the obtained reaction solution is cooled, use acetone, alcohol and deionized Settle the water and centrifuge to remove glycerol and PVP, and then dry at 80°C for 10 hours to obtain the target product micron silver wire. Or without drying, the micron silver filaments are preserved and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com