Iron-aluminum composite steel ring and manufacturing method thereof

A technology of composite steel and manufacturing methods, which is applied in the direction of metal processing equipment, etc., can solve the problems of difficult to manufacture rims with complex shapes, difficult to meet high-quality vehicles, and high price of aluminum alloy rims, so as to improve the quality level, save the process, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

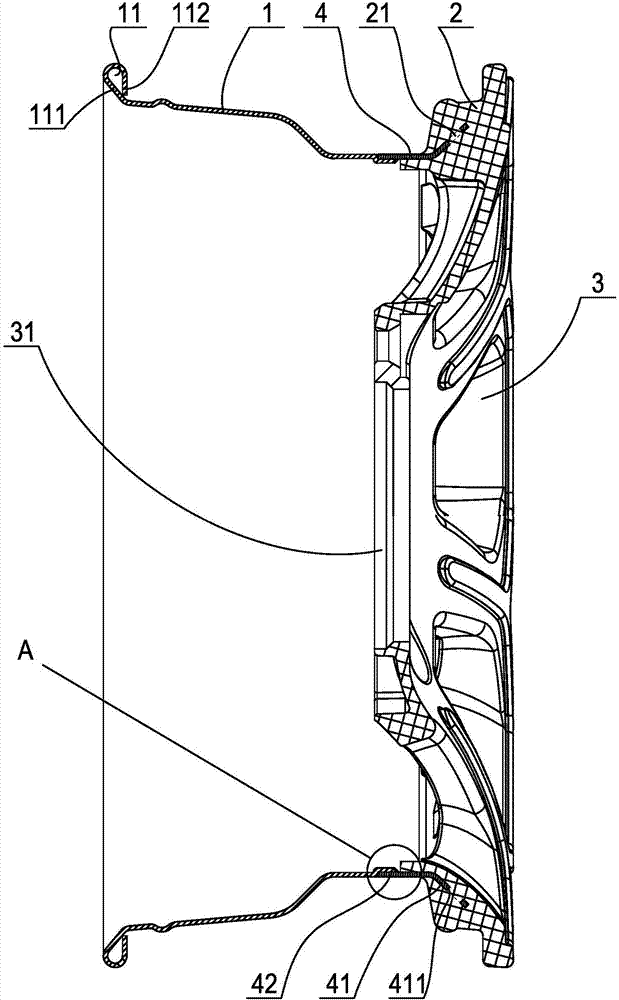

[0039] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, an iron-aluminum composite steel ring includes a ring body, the ring body includes a left ring body 1 and a right ring body 2 coaxially arranged side by side, and the left ring body is a steel cylinder made by a stamping forming process The right ring body is provided with a panel 3, and the right ring body and the panel are made into an integrated structure through an aluminum alloy die-casting process. A transition ring body 4 is arranged on the left side of the right ring body. The transition ring body includes a The connected embedded section 41 and the welding section 42 protruding from the right ring body, the transition ring body is also a steel cylindrical member made by stamping and forming process. When the right ring body and the panel are die-casted, the transition ring body is used as an insert of the die-casting mold, so that the embedded section at the right end of the transition ring body is em...

Embodiment 2

[0044] Embodiment 2: A method for manufacturing an iron-aluminum composite steel ring, which is suitable for manufacturing the iron-aluminum composite steel ring described in Embodiment 1, specifically comprising the following steps:

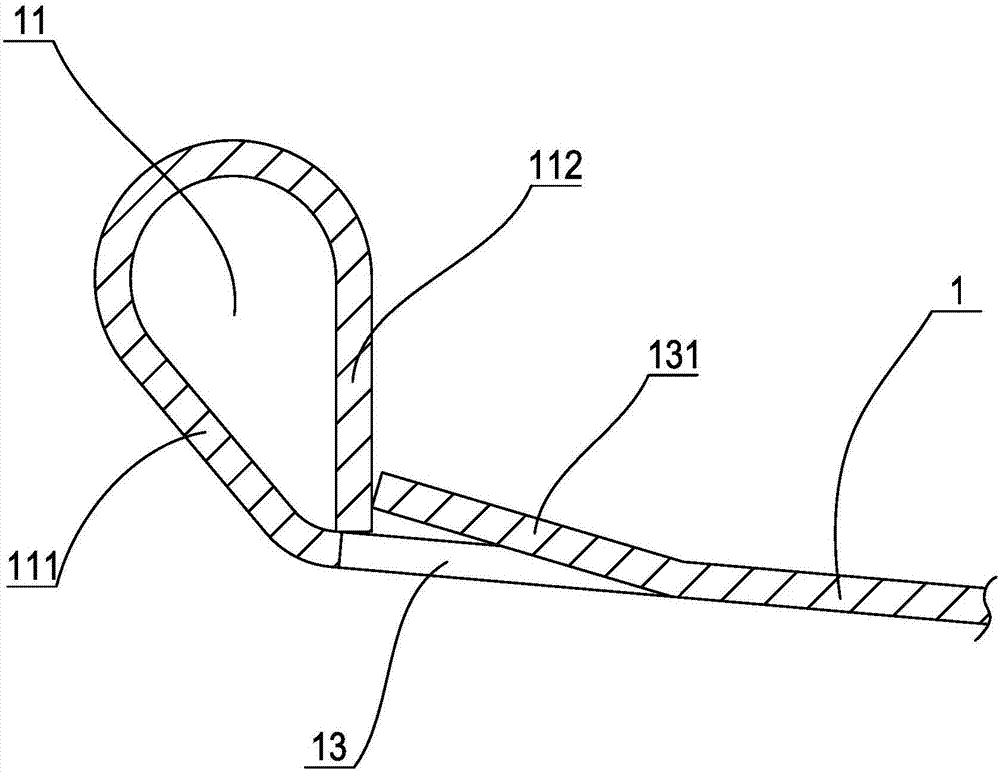

[0045] a. First process the cylindrical left ring body and the transition ring body through the stamping process. The transition ring body includes a cylindrical welding section and a conical embedded section that expands outwards, and the embedded section A number of connecting through holes evenly distributed in the circumferential direction are punched out, and at the same time, the edge of the left end of the left coil body is turned over by the curling process to produce the everted curl;

[0046] b. Such as Figure 4As shown, the cylindrical welding section of the transition ring body is sleeved on the mold core 61 of the lower mold 6 of the aluminum alloy die-casting mold installed on the die-casting machine, and the upper mold 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com