Method and device for denitration, desulfurization and dust removal of FCC tail gas through ammonia process

A technology for desulfurization, dust removal, and denitrification, applied in the field of environmental protection, can solve the problems of high investment and operating costs, narrowing of the selection range, and difficulty in long-term stable operation of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

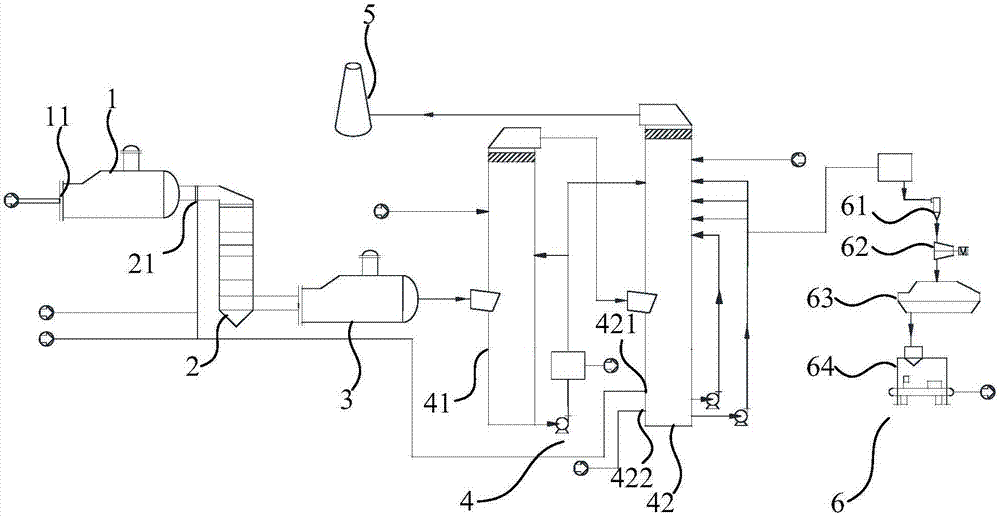

Embodiment 1

[0070] This embodiment provides a 1 million tons / year FCC tail gas ammonia method denitrification, desulfurization and dust removal device, which includes a first-level waste heat recovery system 1, a denitrification system 2, a second-level waste heat recovery system 3, a dust removal and desulfurization system 4, and a tail gas discharge system 5 and ammonium sulfate post-treatment system 6, an FCC tail gas inlet 11 is provided on the first-level waste heat recovery system 1; the denitrification system 2 is connected to the first-level waste heat recovery system 1, and a denitrification reducing agent inlet 21 is provided; the second-level waste heat recovery system 3 is connected to the denitrification system 2; the dust removal and desulfurization system 4 is set separately, including a dust removal device and a desulfurization device. The dust removal device in this embodiment adopts a dust removal tower 41, and the dust removal tower 41 is connected to the secondary waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com