Dust removing method of spring tube dust remover

A dust collector and spring cartridge technology, applied in chemical instruments and methods, separation methods, membrane filters, etc., can solve problems such as slow cleaning work, decreased air permeability, cumbersome operation, etc., to improve cleaning speed, prevent excessive flying, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

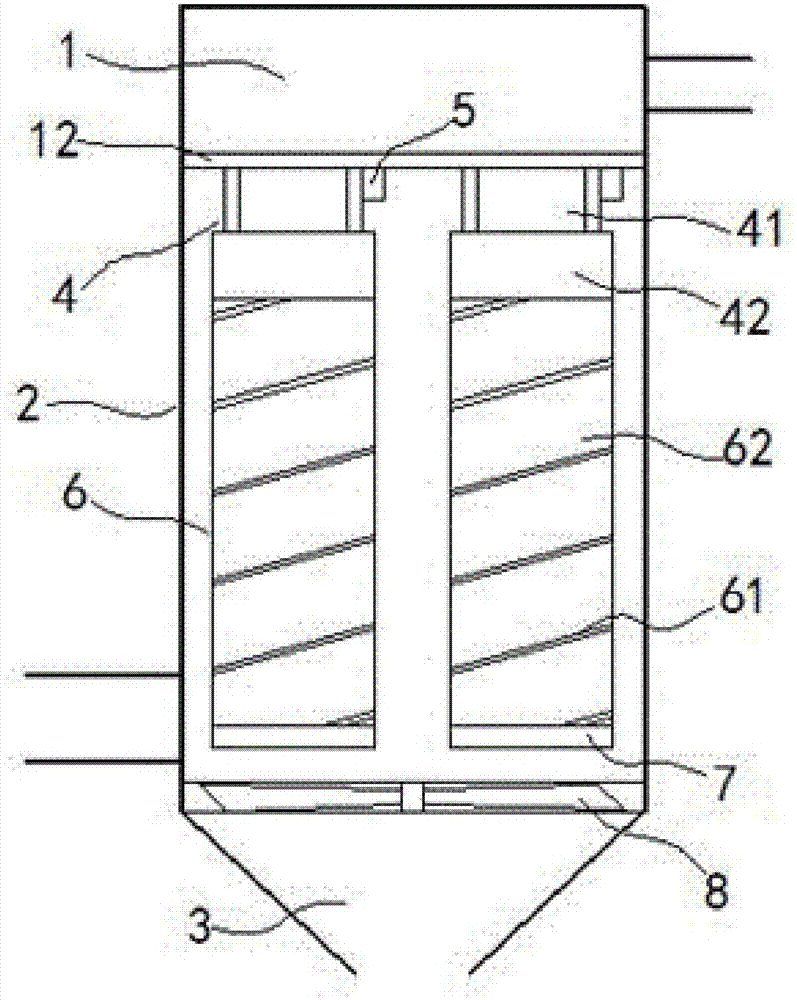

[0012] exist figure 1 In the shown embodiment, the spring cartridge dust collector includes a dust removal chamber 2, a clean chamber 1 and an ash hopper 3; Below; between the clean chamber 1 and the dedusting chamber 2 are separated by a partition 12; an air inlet pipe is installed on the side wall of the dedusting chamber 2, and an exhaust pipe is installed on the side wall of the dedusting chamber 1; The lower surface of the plate 12 is rotationally symmetrically distributed with dust removal units 4. The dust removal unit 4 includes a fixed shaft 41 and an electromagnetic ring 42. A vibrator 5 is installed on the fixed shaft 41. The electromagnetic ring 42 can move along the fixed shaft 41. The axis reciprocatingly slides; the electromagnetic ring 42 is electrically connected to the dust removal power supply; the dust removal power supply is a pulse current; the dust removal cylinder 6 is fixedly installed below the electromagnetic ring 42, and the dust removal cylinder 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com