Production line of macaroni rice vermicelli

A production line and assembly line technology, applied in the fields of food forming, food science, application, etc., can solve the problems of product quality being easily affected by fluctuations in human factors, low production efficiency, poor operating environment, etc., so as to reduce the impact of human factors on quality. probability, cost savings, and the effect of reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

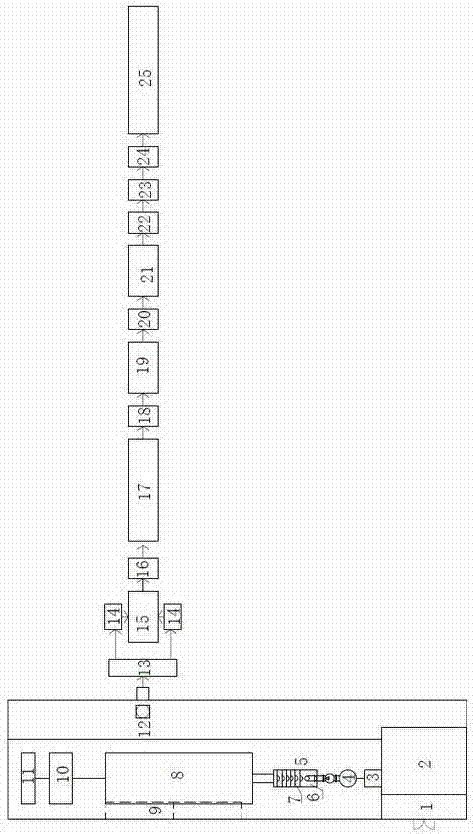

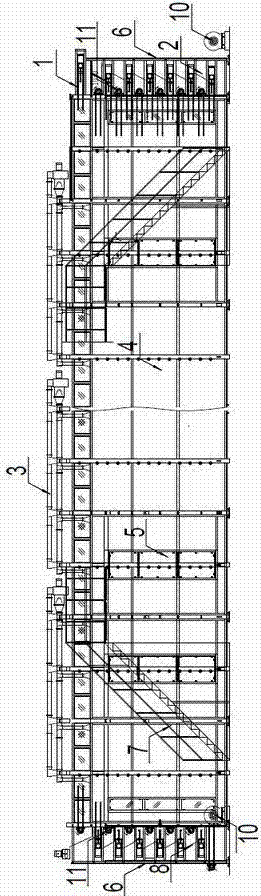

[0012] A production line for macaroni rice noodles, including a cyclone separation rice suction device, a rice storage bucket, a jet washing rice washing and sand removal device, a rice soaking bucket, a draining bucket, a pulverizer, a powder storage bucket, a conveying facility, a flour mixing machine, and a feeding outlet Shred powder cutting machine, primary aging box, steaming material box, secondary aging box, loosening machine, oven. The rice is sent into the rice bin 2 through the hoist 1, and the morning and evening rice is sent into the rice storage tank 4 through the cyclone separation rice suction device 3 after a specific ratio, and the rice in the rice storage tank 4 is sent into the sand removal tank 5 through the water pump jet (Remove stone sand by the principle of different density of rice and stone sand), (the inside of the jet washing rice sand removal device is a cavity, and there are multiple silica gel plates 7 fixed on the stainless steel plate 6 device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com