Assembly type tool hoe, hoe manufacturing method and mould

An assembled and tool-based technology, which is applied in the field of hand tools, can solve the problems of increased product manufacturing costs, shortened mold life, and low precision requirements, and achieves the effects of improving work efficiency and economic benefits, reducing occupied space, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

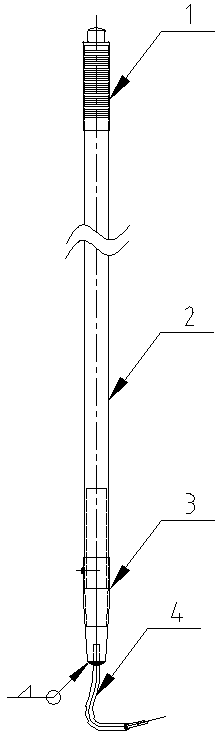

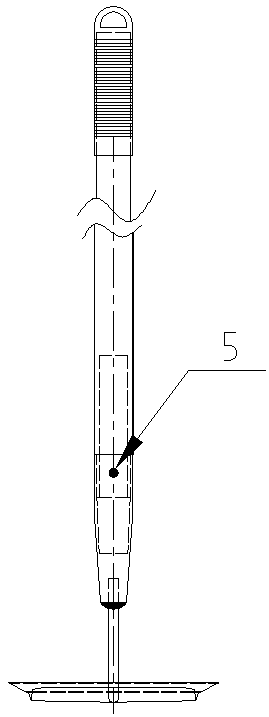

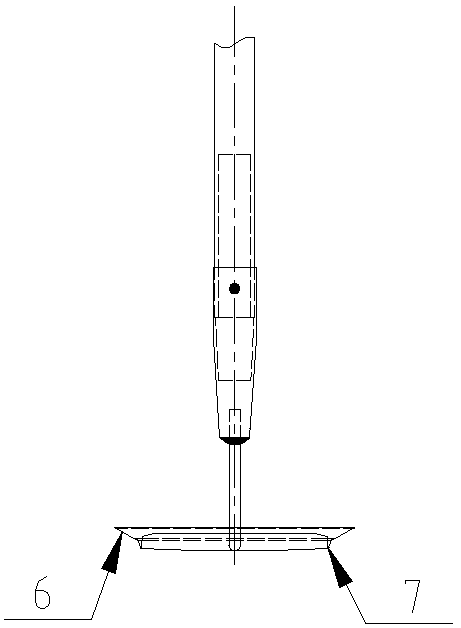

[0081] See attached Figure 1-7 , The assembled tool hoe disclosed in the present invention includes a tool hoe head, a rod and a tail sleeve. The tool hoe head and the rod are connected by shrinking tubes, and the tail end of the rod is covered with a tail cover. As a preference, the tail cover is a plastic sleeve with holes.

[0082] The tool hoe head includes a hoe piece, a fixed splint, a fastening pressing piece and a hoe beam. The hoe beam is an L-shaped structure, and the bending part of the hoe beam is an arc-shaped structure with a smooth transition. The fixed splint has a U-shaped structure, its sealing end is fixedly connected with the hoe beam, and the middle and rear part of the bottom splint is provided with a fastening pressing piece; one end of the fastening pressing piece is connected with the splint as a whole, and the other end is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com