Steering shaft for a motor vehicle

A technology for motor vehicles and steering shafts, which is applied to motor vehicles, steering control mounted on vehicles, bearings for linear motion, etc., can solve problems such as unsatisfactory assembly capacity, complicated manufacturing, and complicated handling, and achieve simple manufacturing technology, Effects of improved handling and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the various figures, like elements are always provided with the same reference numerals, and therefore also usually each element is named or mentioned only once.

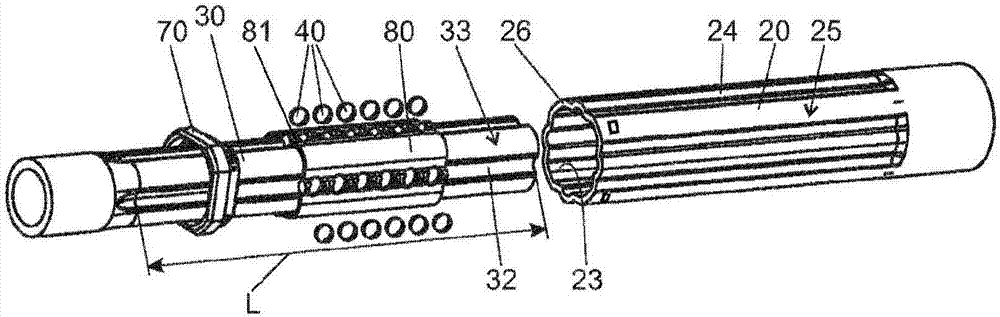

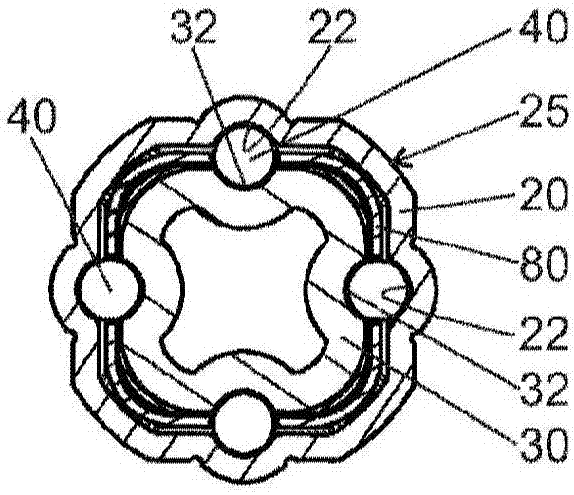

[0036] figure 1 shows a schematic perspective view of the steering shaft 10 shown, which comprises an outer hollow shaft 20 and an inner hollow shaft 30 that are telescopic with respect to each other in the direction of the longitudinal axis, ie in the longitudinal direction indicated by the double-headed arrow .

[0037] At the free end facing away from the inner shaft 30 in the longitudinal direction, the outer hollow shaft 20 comprises a fork 21 forming part of a universal joint via which the steering shaft 10 is connected in a torque-transmitting manner to the steering train. Thus, at the free end facing away from the outer shaft 20 in the longitudinal direction, the inner hollow shaft 30 comprises a bifurcation 31 forming part of another universal joint through which the steering shaft 10 passes in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com