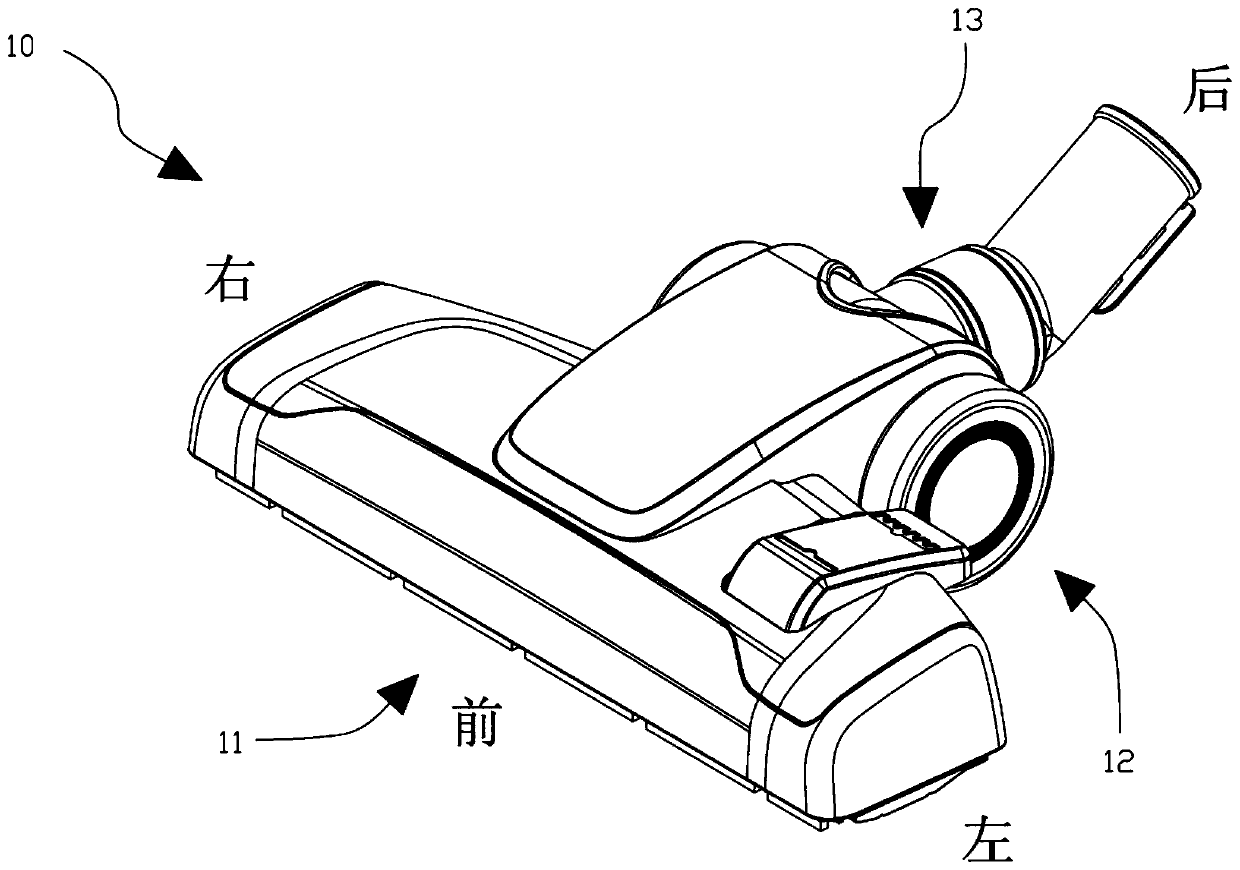

Floor brushes and vacuum cleaners

A vacuum cleaner and suction port technology, applied in the direction of suction nozzles, etc., can solve the problems of increasing maintenance difficulty, processing complexity, increasing parts and components, etc., and achieve the effects of low production and maintenance costs, high dust removal efficiency, and reasonable location.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

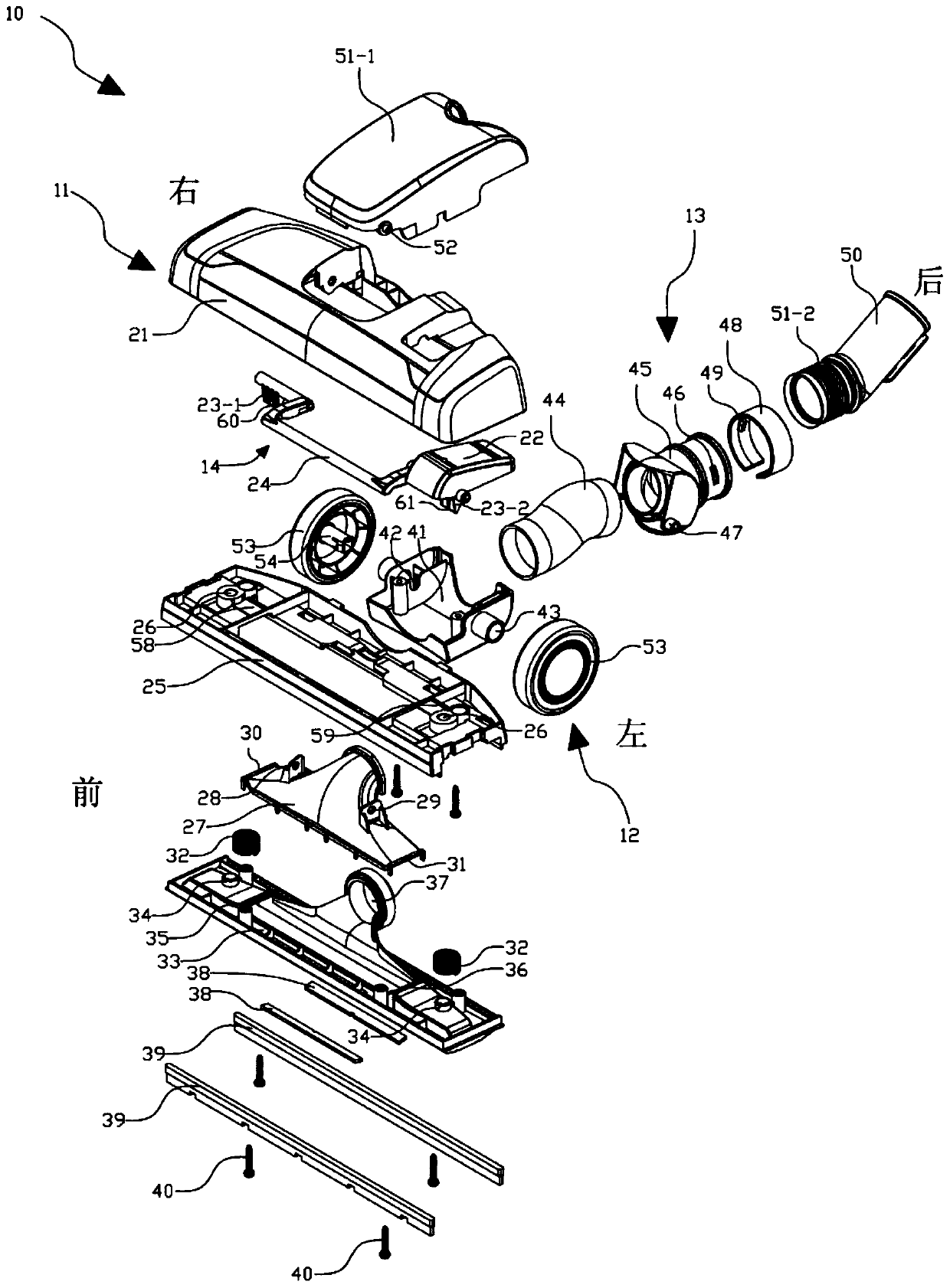

[0025] Hereinafter, the floor brush of the present invention and the vacuum cleaner including the floor brush will be described in detail with reference to the accompanying drawings.

[0026] As a first embodiment, the present invention provides a floor brush, which is used in conjunction with the air duct of a vacuum cleaner to clean the floor, and has such features, including: a main body assembly, including: a bottom plate, provided with a suction slot for sucking air And the air port connected with the air pipe; and the upper cover, which forms a main body cavity with the bottom plate; the air duct assembly, including: the air guide cover, which is connected with the bottom plate to form a suction port for air intake; the hose, whose front end is connected with the air port of the bottom plate , used to guide the wind to enter from the air outlet; elbow sleeve, the front end is connected with the rear end of the hose to prevent air leakage; elbow pipe, the front end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com