Water diversion annular trough type water outlet bearer

A water-splitting ring, grooved technology, applied in the magnetic circuit shape/style/structure, electric components, cooling/ventilation devices, etc., can solve the problem of affecting the operation safety of the generator, the expansion of the cooling water volume, and the impact on the water outlet support. The problems of arc flat plate and side wall, etc., achieve the effect of novelty, reasonable structure and remarkable technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

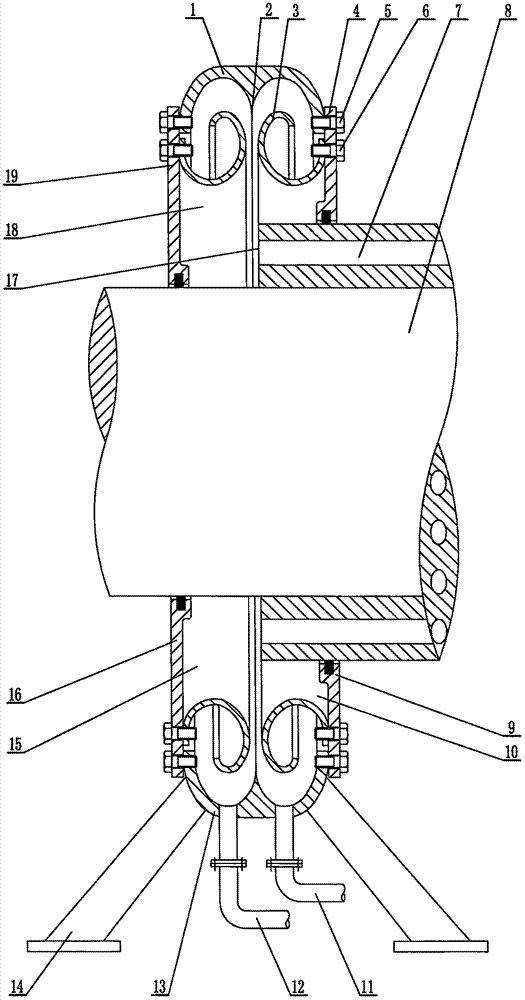

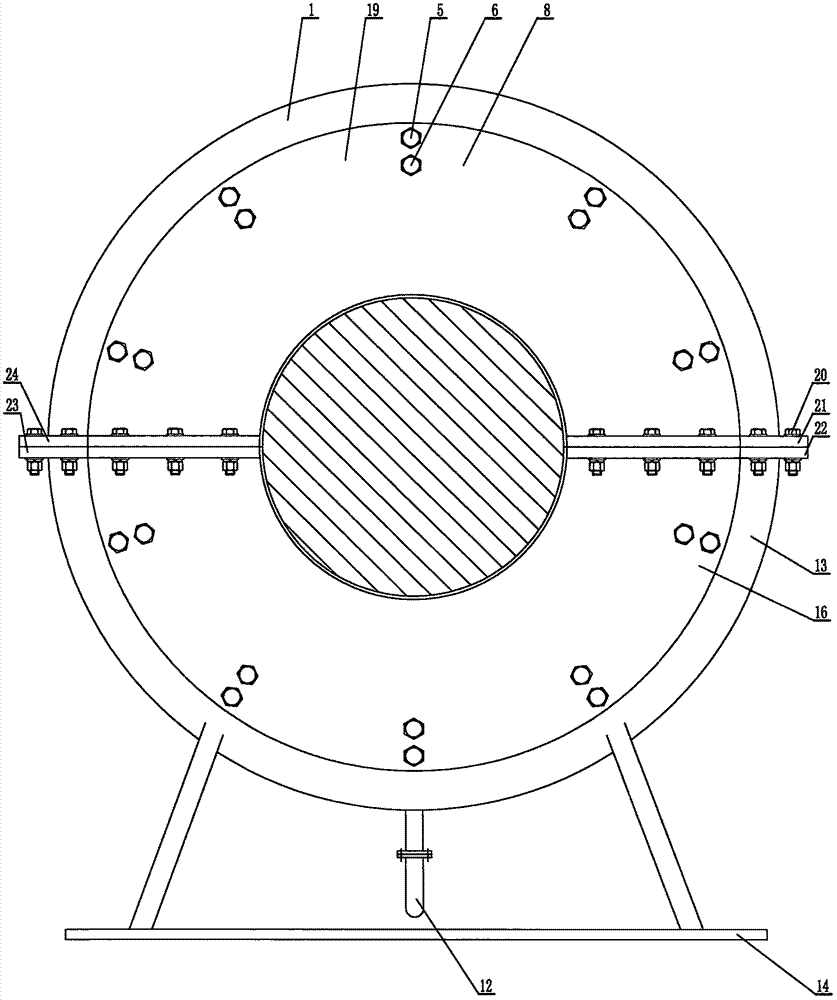

[0017] Fix the upper right water guide ring groove 3 to the upper right end cover 4 with the ring groove bolts 6 respectively, fix the lower right water guide ring groove 10 to the lower right end cover 9, and fix the upper left water guide ring groove 18 to the upper left end cover 19 Up, fix the left lower water guide ring groove 15 on the left lower end cover 16. The right drainage pipe 11 and the left drainage pipe 12 are fixed on the lower water diversion annular guide cavity 13 with two brackets 14 and connected in parallel. Fix the left lower end cover 16 with the left lower water guide ring groove 15 on the left side of the lower water diversion annular guide cavity 13 with the end cover bolt 5, and use the end cover bolt 5 to fix the right lower end cover with the right lower water guide ring groove 10 9 is fixed on the right side of the annular guide cavity 13 in the lower flap. Put the large shaft 8 on the inner diameter of the lower right end cover 9 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com