Six degrees of freedom loading test bench

A technology of loading test and degree of freedom, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc. It can solve the problems of long test period, inability to simulate composite working condition tests, single direction loading, etc., and achieve simple structure , shorten the test cycle, and the effect of small mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure and characteristics of the six-degree-of-freedom loading test bench proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. And its effect, detailed description is as follows.

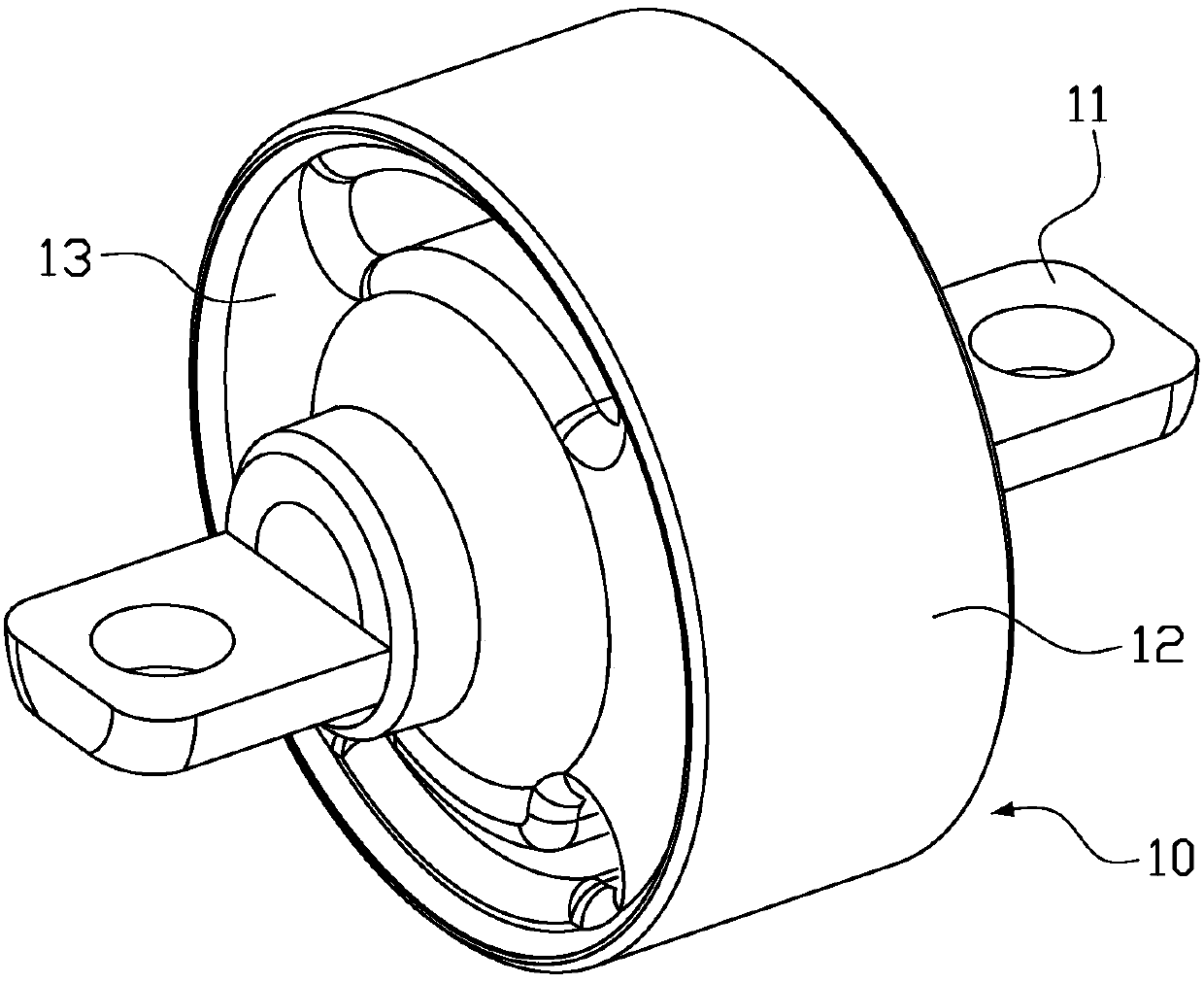

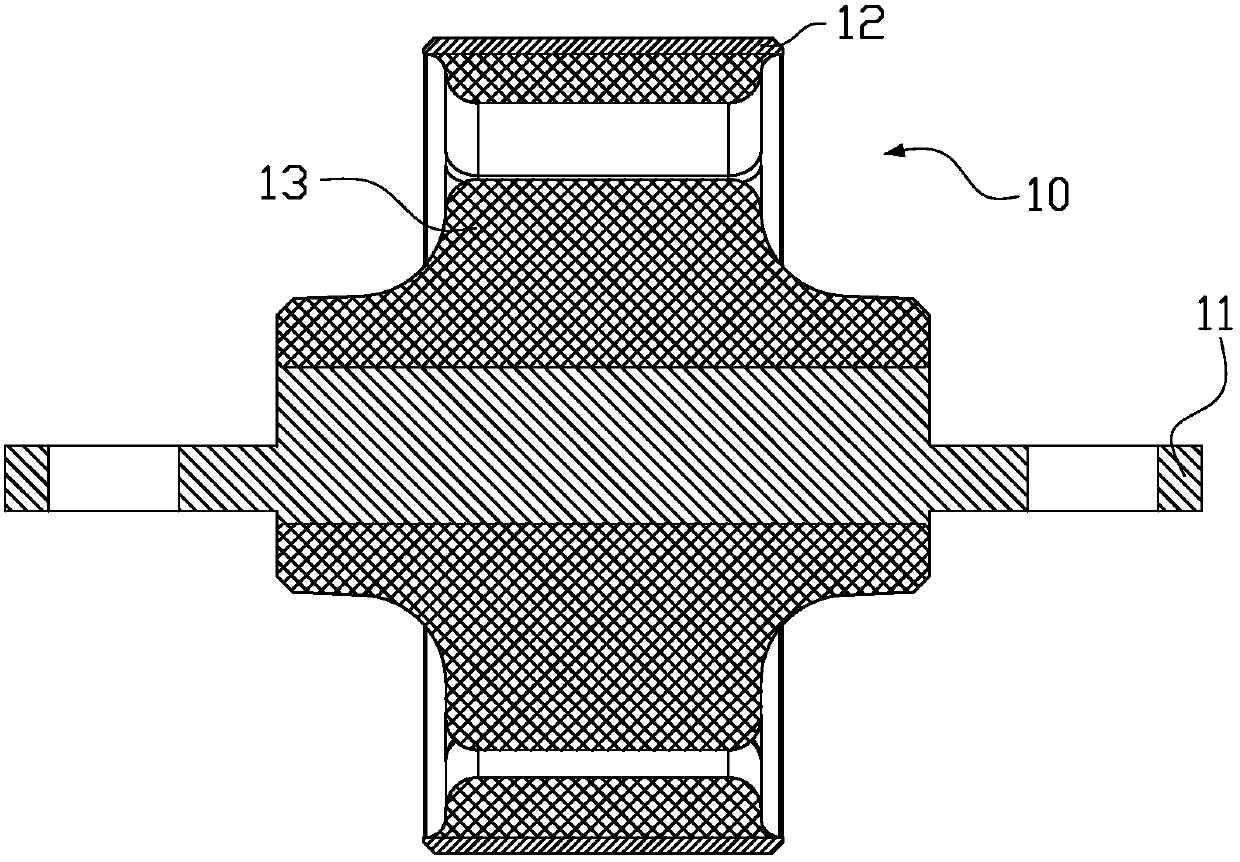

[0029] First of all, it should be noted that the six-degree-of-freedom loading test bench of the present invention can be used for fatigue tests and strength tests of bushing parts. In this embodiment, the test sample is the bushing 10 of the swing arm, and the bushing 10 The structure is as figure 1 with figure 2 As shown, it includes an inner rod 11 , an outer tube 12 , and rubber 13 filled between the inner rod 11 and the outer tube 12 .

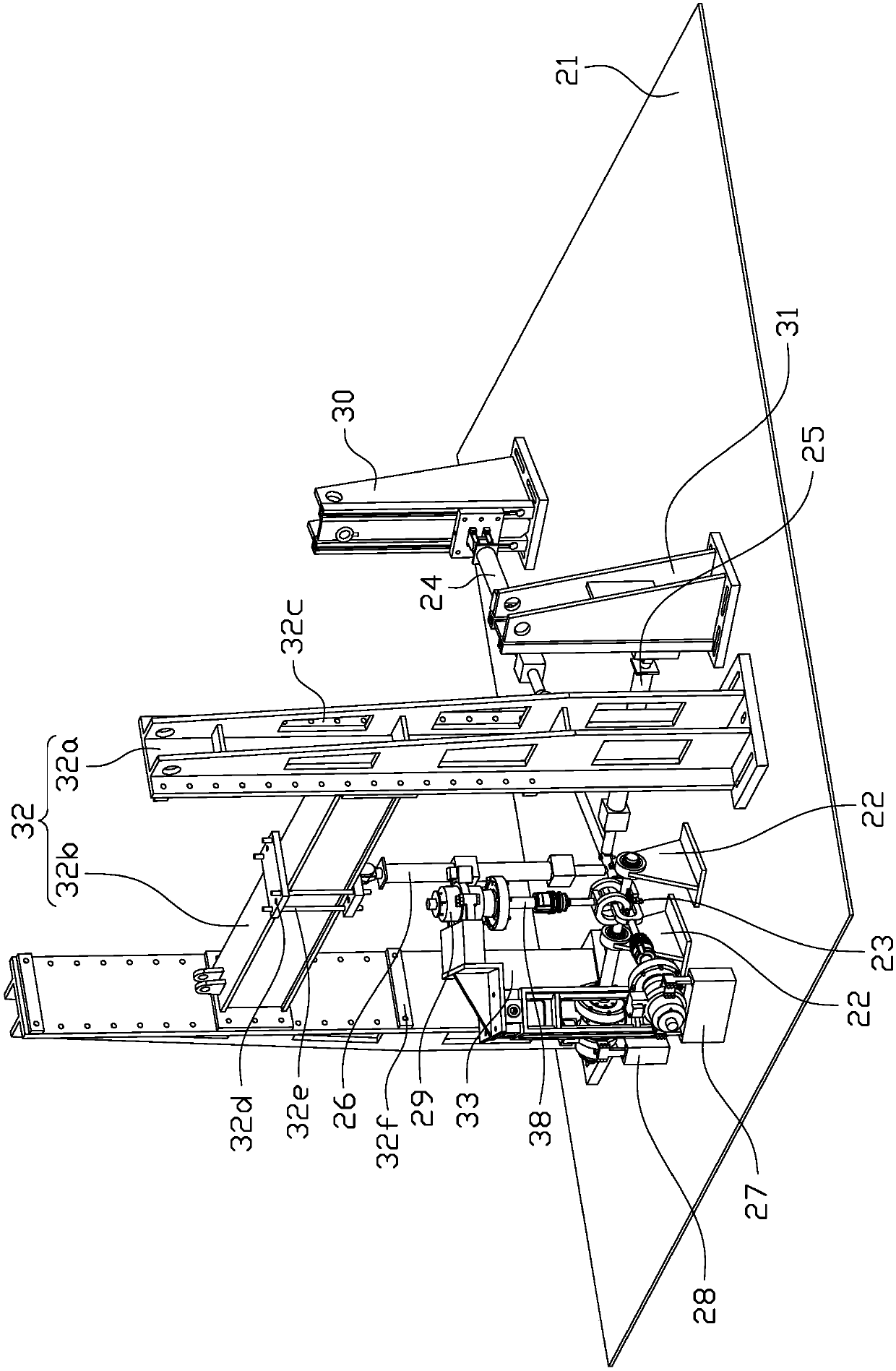

[0030] Such as image 3 and Figure 4 As shown, the six-degree-of-freedom loading test bench of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com