Asparagus farmyard manure and a preparing method thereof

A technology of farmyard manure and asparagus, which is applied in the field of asparagus farmyard manure and its preparation, which can solve the problems of reduced ability of crops to resist diseases and insect pests, increase of agricultural cost, closed-type strengthening, etc., to achieve waste utilization and sustainable recycling, and realize raw material Effects of standardization and reduction of environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

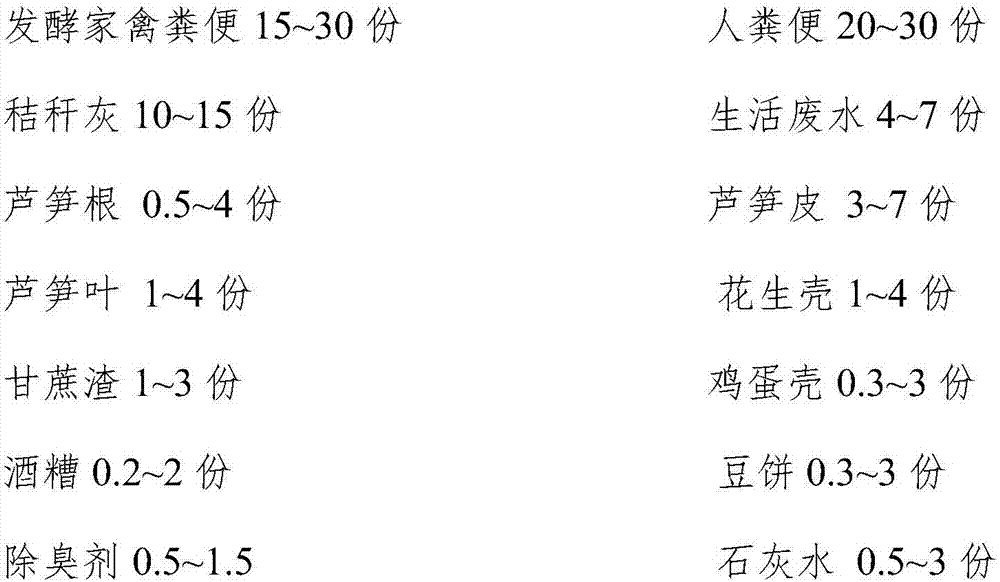

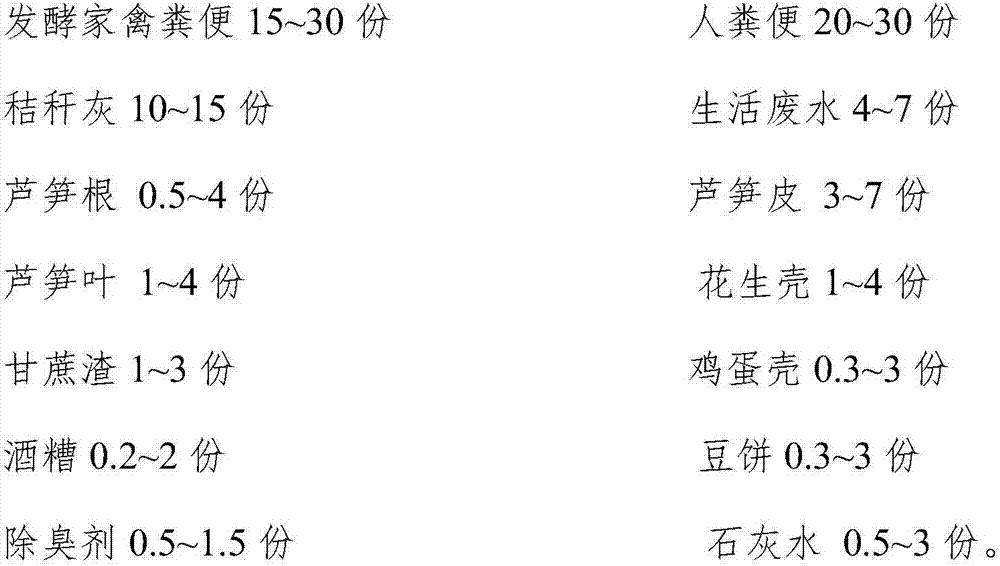

[0019] Raw material formula quantity of asparagus manure: 15 parts of fermented poultry manure, 20 parts of human manure, 10 parts of straw ash, 4 parts of domestic waste water, 0.5 parts of asparagus root, 3 parts of asparagus skin, 1 part of asparagus leaf, 1 part of peanut shell, sugar cane 1 part of slag, 0.3 part of egg shell, 0.2 part of distiller's grains, 0.3 part of bean cake, 0.5 part of deodorant, 0.5 part of lime water;

[0020] Preparation:

[0021] (1) Ingredients and mixing: Weigh fermented poultry manure, human manure, domestic waste water, asparagus root, asparagus skin, asparagus leaves, peanut shells, bagasse, and egg shells into a mixer and mix for 30 to 50 minutes;

[0022] (2) Fermentation: put the mixture of step (1) into an anaerobic fermentation tank at 20-45°C for anaerobic fermentation, the fermentation time is 15 days, and add deodorant after the fermentation is completed;

[0023] (3) Mixing and pulverization: put the fermented product in step (2)...

Embodiment 2

[0026] Raw material formula quantity of asparagus manure: 30 parts of fermented poultry manure, 30 parts of human manure, 15 parts of straw ash, 7 parts of domestic waste water, 4 parts of asparagus root, 7 parts of asparagus skin, 4 parts of asparagus leaf, 4 parts of peanut shell, sugar cane 3 parts of slag, 3 parts of egg shell, 2 parts of distiller's grains, 3 parts of seed cake, 1.5 parts of deodorant, 1 part of lime water;

[0027] Preparation:

[0028] (1) Ingredients and mixing: Weigh the fermented poultry manure, human manure, domestic waste water, asparagus root, asparagus skin, asparagus leaf, peanut shell, bagasse, and egg shell into the mixer and mix for 35-45 minutes;

[0029] (2) Fermentation: put the mixture of step (1) into an anaerobic fermentation tank for anaerobic fermentation, ferment for 10 days, add deodorant after the fermentation is completed;

[0030] (3) Mixing and pulverization: put the fermented product in step (2) into a mixer, adjust the pH val...

Embodiment 3

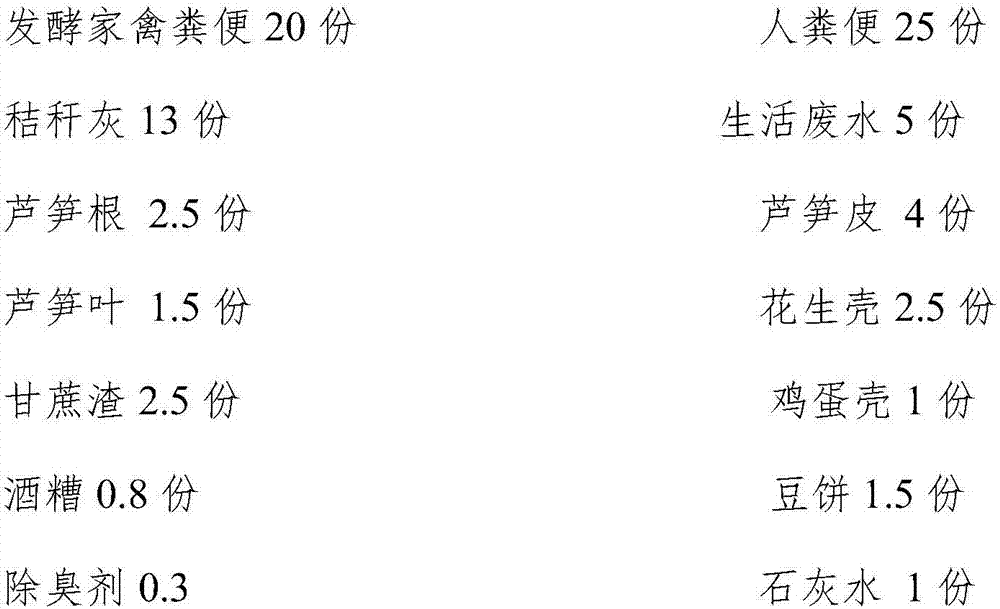

[0033] Raw material formula quantity of asparagus manure: 20 parts of fermented poultry manure, 25 parts of human manure, 13 parts of straw ash, 5 parts of domestic waste water, 2.5 parts of asparagus root, 4 parts of asparagus skin, 1.5 parts of asparagus leaf, 2.5 parts of peanut shell, sugar cane 2.5 parts of slag, 1 part of egg shell, 0.8 part of distiller's grains, 1.5 parts of seed cake, 0.3 parts of deodorant, 3 parts of lime water;

[0034] Preparation:

[0035] (1) Ingredients and mixing: Weigh the fermented poultry manure, human manure, domestic waste water, asparagus root, asparagus skin, asparagus leaf, peanut shell, bagasse, and egg shell into the mixer and mix for 40-50 minutes;

[0036] (2) Fermentation: put the mixture of step (1) into an anaerobic fermentation tank for anaerobic fermentation, ferment for 10 days, add deodorant after the fermentation is completed;

[0037] (3) Mixing and pulverization: put the fermented product in step (2) into a mixer, adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com