Wide-temperature and low-loss soft ferrite

A soft ferrite, low-loss technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problem of power consumption increase, achieve the effect of reducing loss, uniform crystal grains, and reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

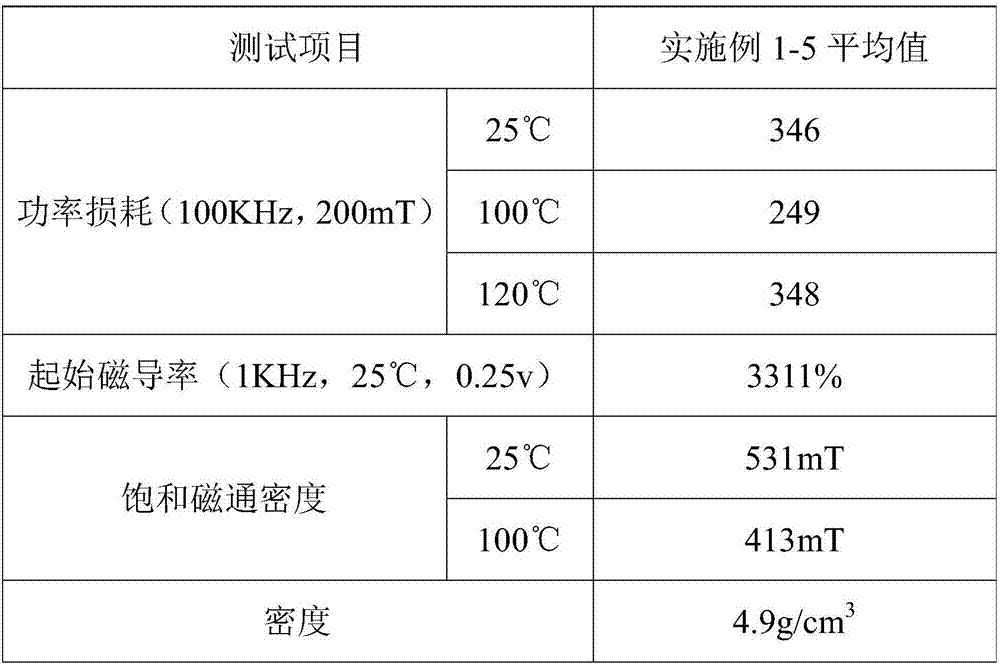

Examples

Embodiment 1

[0017] A kind of soft magnetic ferrite with wide temperature and low loss, its raw materials include by weight: 100 parts of main materials, 0.67 parts of auxiliary materials, 0.4 parts of surfactants, 0.15 parts of defoamers, and 5 parts of binders;

[0018] The raw materials of the main ingredients include by molar ratio: SnO 2 0.65 parts, MnO 12.9 parts, ZnO 33.5 parts, Fe 2 o 3 52.95 copies;

[0019] The raw material of auxiliary material comprises by weight: Co 2 o 3 0.15 parts, Ta 2 o 5 0.065 parts, CaCO 3 0.25 parts, SiO 2 0.12 parts, V 2 o 5 0.035 parts, Li 2 CO 3 0.015 parts, ZrO 2 0.03 parts.

Embodiment 2

[0021] A kind of soft magnetic ferrite with wide temperature and low loss, its raw materials include by weight: 100 parts of main materials, 0.56 parts of auxiliary materials, 0.5 parts of dodecyl dimethyl ammonium bromide, 0.1 parts of defoaming agent, polyvinyl alcohol aqueous solution 6 copies;

[0022] The defoamer is a mixture of polyoxypropylene polyoxyethylene glyceryl ether and higher alcohol fatty acid ester complex;

[0023] The raw materials of the main ingredients include by molar ratio: SnO 2 0.6 parts, MnO 12.5 parts, ZnO 33.2 parts, Fe 2 o 3 53.7 copies;

[0024] The raw material of auxiliary material comprises by weight: Co 2 o 3 0.14 parts, Ta 2 o 5 0.07 parts, CaCO 3 0.2 parts, nano-SiO 2 0.15 parts, V 2 o 5 0.03 parts, Li 2 CO 3 0.02 parts, ZrO 2 0.02 copies;

[0025] In the preparation process of wide temperature and low loss soft ferrite, the SnO 2 , MnO, ZnO, Fe 2 o 3 Mix with surfactant, grind for 90 minutes, heat up to 400°C, p...

Embodiment 3

[0027] A kind of soft magnetic ferrite with wide temperature and low loss, its raw materials include by weight: 100 parts of main materials, 0.78 parts of auxiliary materials, 0.3 parts of cetyltrimethylammonium chloride, 0.2 parts of defoaming agent, epoxy resin glue 4 parts;

[0028] The defoamer is a mixture of polyoxypropylene polyoxyethylene glyceryl ether and higher alcohol fatty acid ester complex;

[0029] The raw materials of the main ingredients include by molar ratio: SnO 2 0.7 parts, MnO 13.3 parts, ZnO 33.8 parts, Fe 2 o 3 52.2 copies;

[0030] The raw material of auxiliary material comprises by weight: Co 2 o 3 0.16 parts, Ta 2 o 5 0.06 parts, CaCO 3 0.3 parts, nano-SiO 2 0.1 parts, V 2 o 5 0.04 parts, Li 2 CO 3 0.01 parts, ZrO 2 0.04 copies;

[0031] In the preparation process of wide temperature and low loss soft ferrite, the SnO 2 , MnO, ZnO, Fe 2 o 3 Mix with surfactant, grind for 60 minutes, heat up to 450°C, pre-fire for 30 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com