Vibrating motor

A vibration motor and vibration direction technology, applied in electrical components, electromechanical devices, etc., can solve the problems of poor connection strength, motor failure, easy deformation, etc., and achieve the effect of low repair rate, prevention of tearing, and stable electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

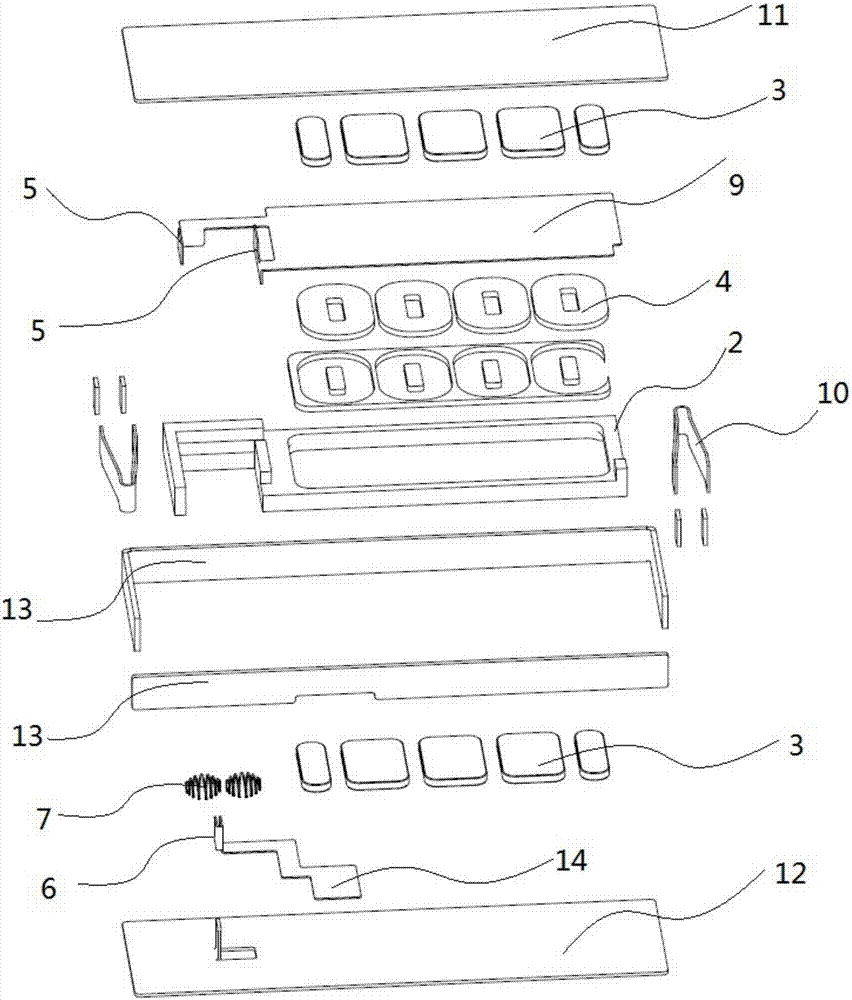

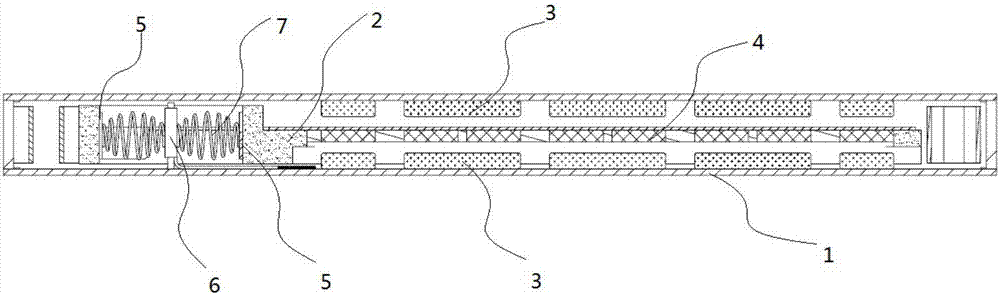

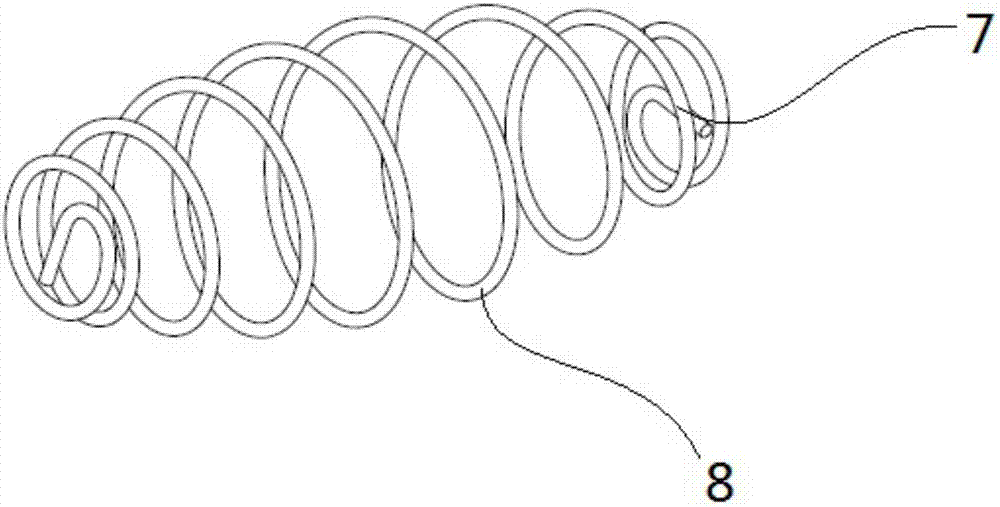

[0051] figure 1 It is an exploded view of the vibration motor provided in Embodiment 1 of the present invention; figure 2 for figure 1 Cutaway view of the vibrating motor shown; image 3 for figure 1 Schematic diagram of the structure of the drum spring shown; Figure 4 for figure 1 Schematic diagram of the structure of the conductive spring shown. Such as Figure 1-4 As shown, the vibration motor provided by this embodiment includes a housing 1 with a housing space, a mass block 2 suspended in the housing space through an elastic member 10, a stator is fixed on the housing, and the stators include housings 1 that are fixedly arranged respectively. The two sets of magnets 3 on the two inner surfaces facing each other, the mass block 2 is located between the two sets of magnets 3, the vibrator includes a coil 4 fixedly arranged on the mass block 2, and the coil 4 is covered with a first coil electrically connected to the coil 4 An FPC board 9 is provided with two moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com