A low-temperature lithium-ion battery

A lithium ion battery, low temperature technology, applied in the field of lithium ion batteries, can solve the problems of high energy density batteries, low capacity, etc., achieve the best low temperature discharge performance, long cycle life, and improve the effect of high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

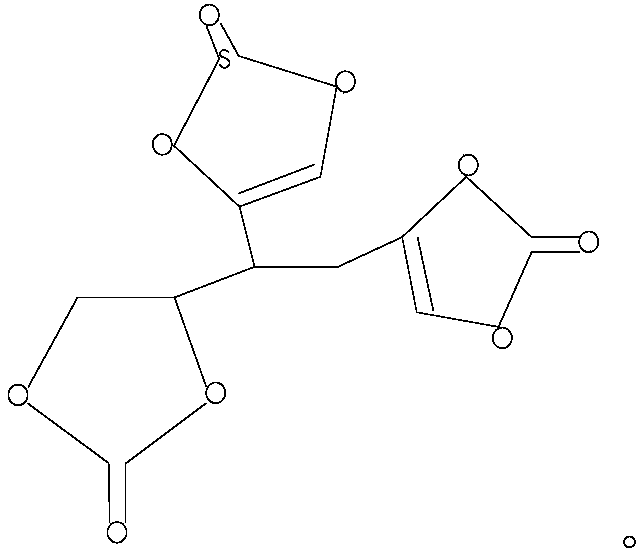

Image

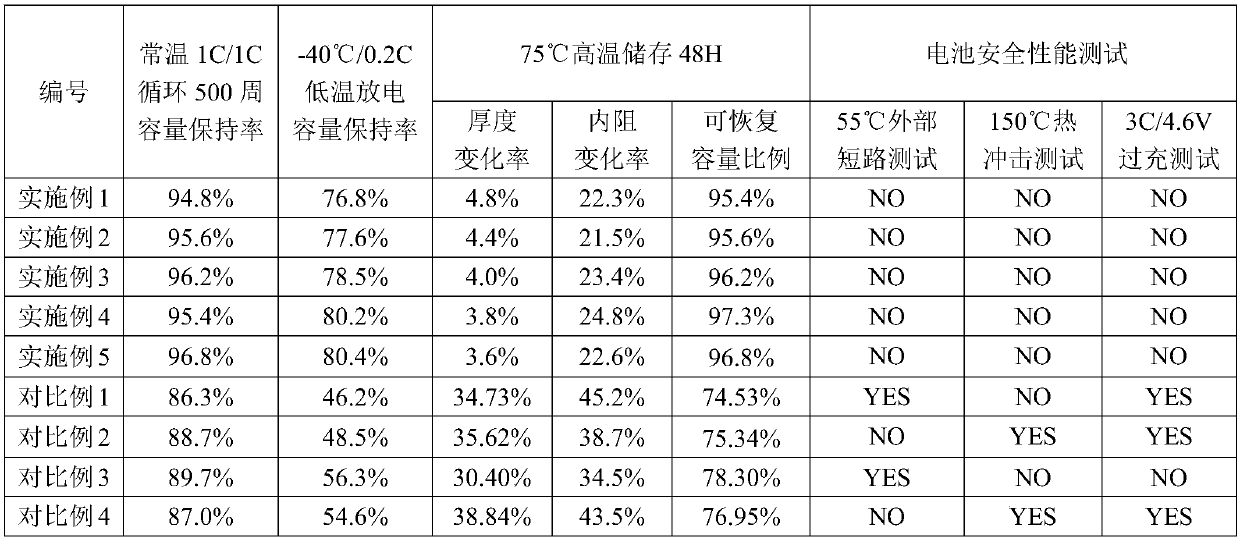

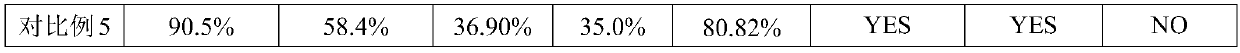

Examples

Embodiment 1

[0020] Preparation of positive electrode sheet: Lithium cobaltate, conductive carbon black, and binder polyvinylidene fluoride are uniformly mixed in NMP at a mass ratio of 97:1.0:2.0 to prepare a positive electrode slurry. The solid content of the obtained positive electrode slurry is 70%, viscosity 4000mPa·s, evenly coated on both sides of aluminum foil after passing through 200 mesh sieve, coating weight 18mg / cm 2 , press the coated pole piece at 4.15g / cm 3 The compaction density is rolled to a certain thickness, and finally edge trimming, cutting and slitting are carried out to obtain the positive electrode sheet of lithium-ion battery.

[0021] Preparation of negative electrode sheet: uniformly mix artificial graphite, CMC, SBR, and carbon nanotubes in deionized water at a mass ratio of 95.6:1.2:2.2:1.0 to prepare negative electrode slurry. The solid content of the obtained negative electrode slurry is 46%. Viscosity is 2500mPa·s, evenly coated on both sides of copper fo...

Embodiment 2

[0026] Preparation of positive electrode sheet: uniformly mix nickel-cobalt lithium manganese oxide, conductive agent carbon nanotubes, and binder polyvinylidene fluoride in NMP at a mass ratio of 96.5:1.0:1.5 to prepare a positive electrode slurry. The obtained positive electrode slurry The solid content is 65%, the viscosity is 3800mPa·s, and evenly coated on both sides of the aluminum foil after passing through a 200-mesh sieve, and the coating weight is 15mg / cm 2 , press the coated electrode piece at 3.45g / cm 3 The compaction density is rolled to a certain thickness, and finally edge trimming, cutting and slitting are carried out to obtain the positive electrode sheet of lithium-ion battery.

[0027] Preparation of negative electrode sheet: Mix natural modified graphite, CMC, SBR, and conductive carbon black in deionized water at a mass ratio of 96:1.0:2.0:1.0 to prepare negative electrode slurry. The solid content of the obtained negative electrode slurry is 40 %, with a...

Embodiment 3

[0032] Preparation of positive electrode sheet: Lithium cobaltate, conductive agent carbon nanotubes, and binder polyvinylidene fluoride are uniformly mixed in NMP at a mass ratio of 99:0.5:0.5 to prepare a positive electrode slurry. The solid content of the obtained positive electrode slurry is 75%, the viscosity is 4200mPa·s, and evenly coated on both sides of the aluminum foil after passing through a 200-mesh sieve, the coating weight is 25mg / cm 2 , press the coated pole piece at 4.0g / cm 3 The compaction density is rolled to a certain thickness, and finally edge trimming, cutting and slitting are carried out to obtain the positive electrode sheet of lithium-ion battery.

[0033] Preparation of negative electrode sheet: uniformly mix artificial graphite, CMC, SBR, and conductive carbon black in deionized water at a mass ratio of 97:1.0:1.0:1.0 to prepare negative electrode slurry. The solid content of the obtained negative electrode slurry is 50%. Viscosity is 2800mPa·s, ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com