Surface acoustic wave temperature sensor-based intelligent temperature measurement composite insulator system

A technology of temperature sensor and composite insulator, used in thermometers, insulators, thermometers with physical/chemical changes, etc., can solve problems such as installation difficulties, improve uninterrupted maintenance, improve accuracy and reliability, and avoid excessive maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

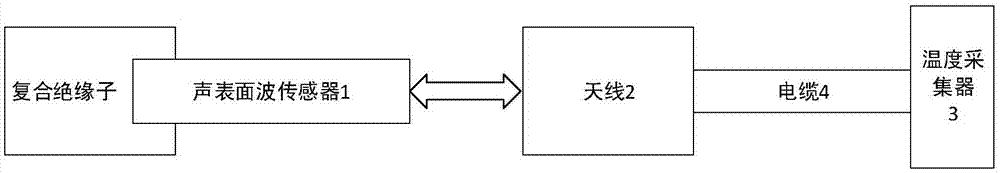

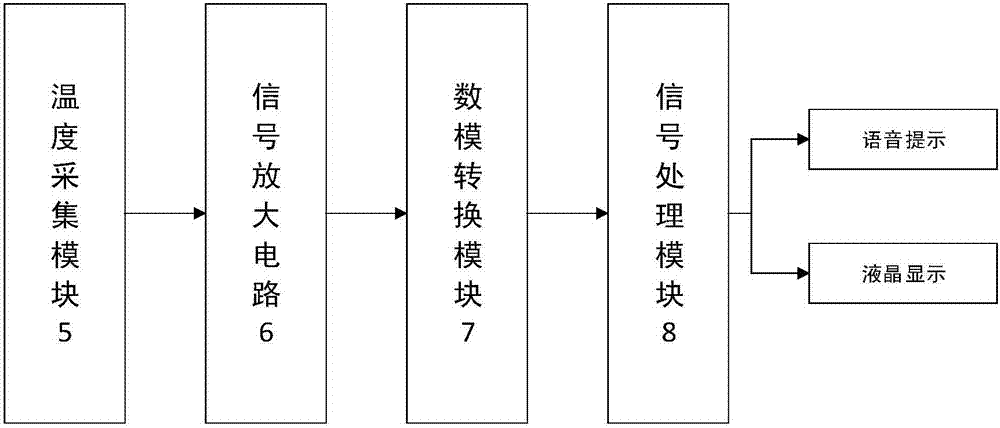

[0013] The composite insulator temperature online monitoring system is mainly composed of a passive wireless surface acoustic wave temperature sensor, and the subsequent signal processing device completes the measurement of the composite insulator temperature. The present invention will be further described below with reference to the accompanying drawings.

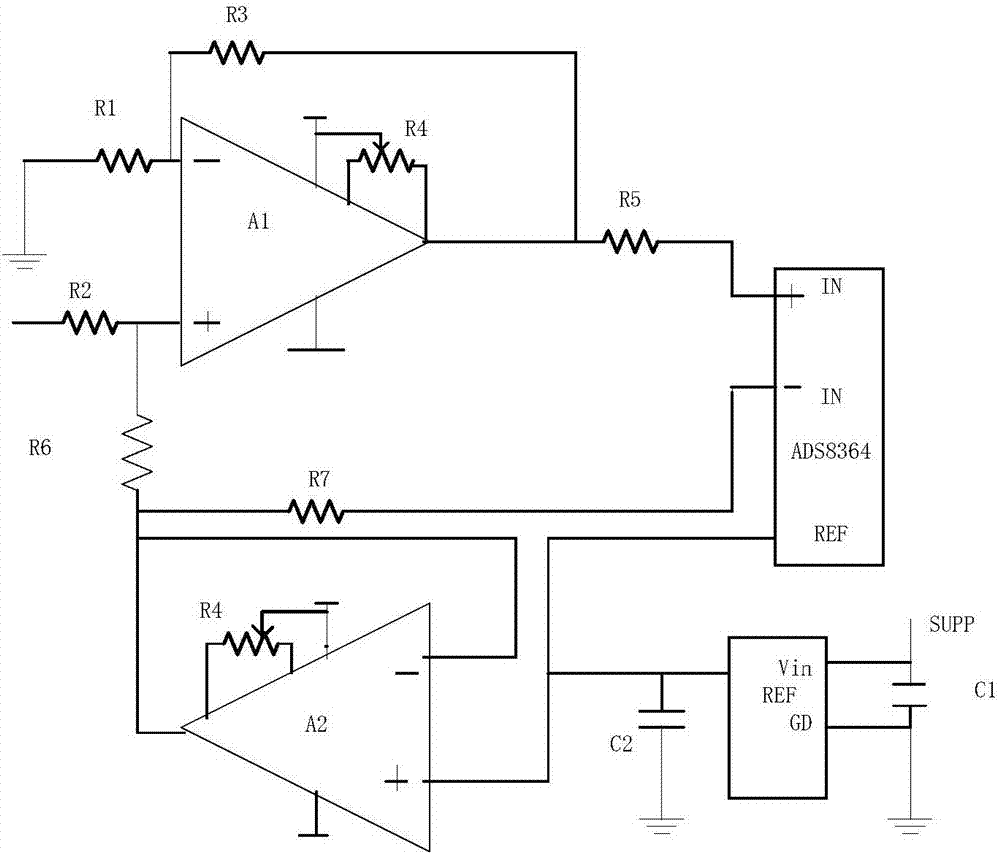

[0014] In the figure, 1. SAW temperature sensor, 2. Antenna (Yagi antenna), 3. Temperature collector, 4. Cable, 5. Temperature acquisition module, 6. Signal amplifier circuit, 7. A / D conversion module, 8 , signal processing module.

[0015] like figure 1 The surface acoustic wave sensor 1 is installed at multiple temperature measurement points on the inner surface of the metal part of the steel cap of the composite insulator, the surface of the glass fiber epoxy resin pulling rod and the lower surface of the shed of the composite insulator. The surface acoustic wave temperature sensor 1 includes a bracket, an outer cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com