Monitorable magnetically-controlled reactor

A technology of magnetically controlled reactors and reactors, which is applied in the directions of reactive power compensation, reactive power adjustment/elimination/compensation, etc., which can solve the inconvenient and accurate thyristor protection, the trigger situation cannot be accurately grasped in real time, and the thyristor trigger status cannot be monitored in real time and other issues to achieve the effect of small ripple and guaranteed triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

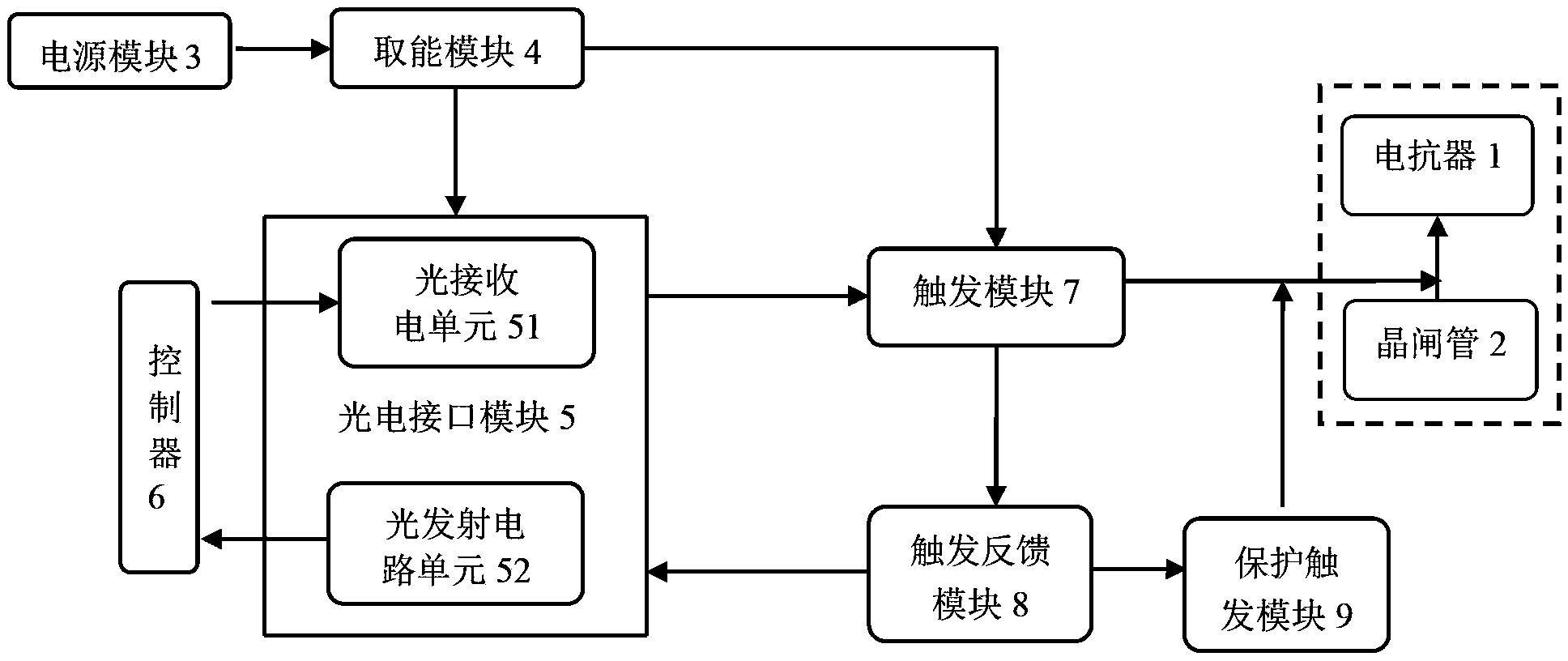

[0022] Example: a monitorable magnetic control reactor, as attached Figure 1~4 As shown, the magnetron reactor includes a reactor 1 and a thyristor 2 for controlling the switching angle of the reactor 1;

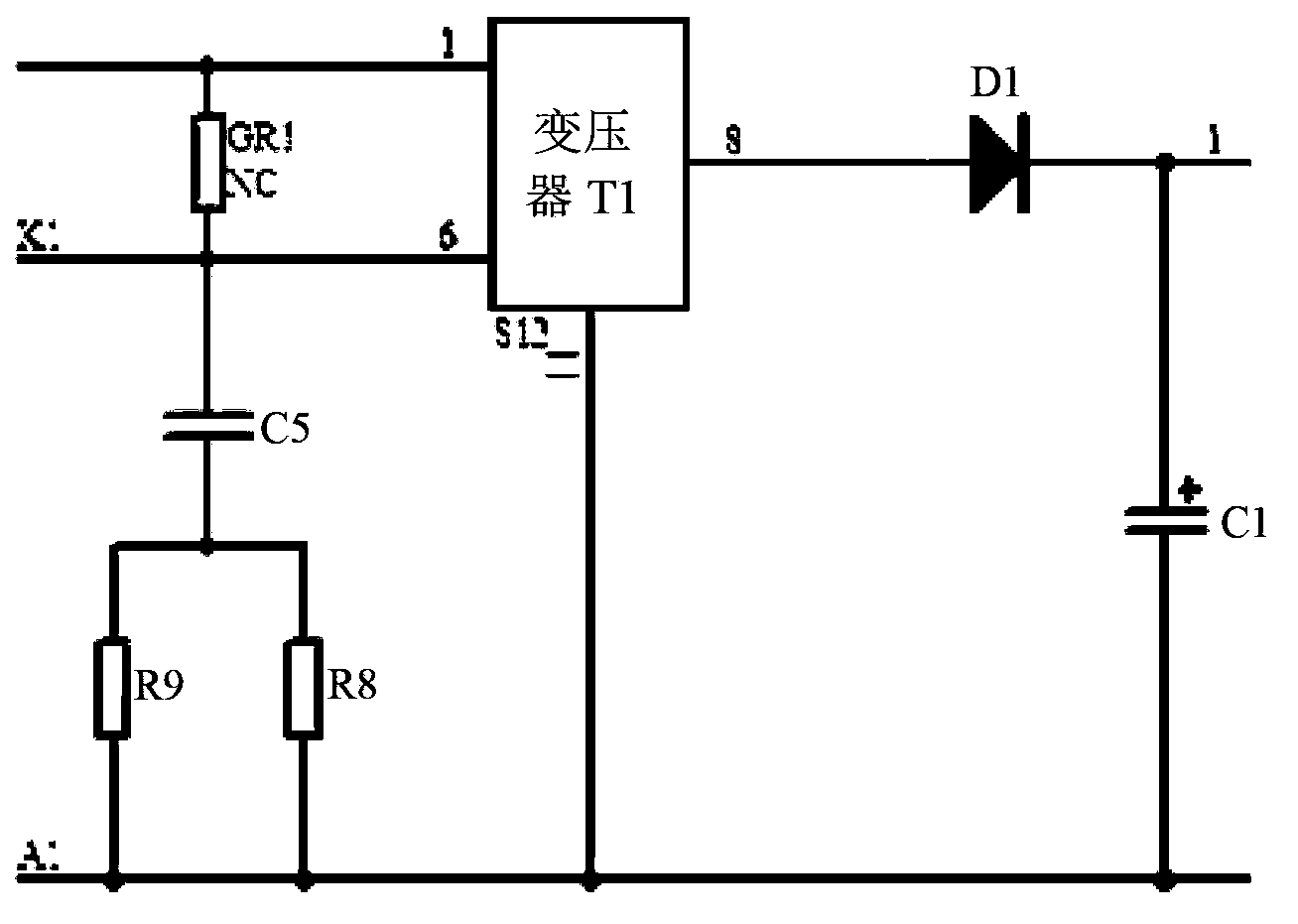

[0023] It also includes: a power module 3 connected to the mains, used to receive electric energy from the grid, which includes a transformer T1 and a first diode D1, the transformer T1 steps down the voltage from the mains and then passes through the first diode D1 Remove the positive half cycle to obtain DC voltage;

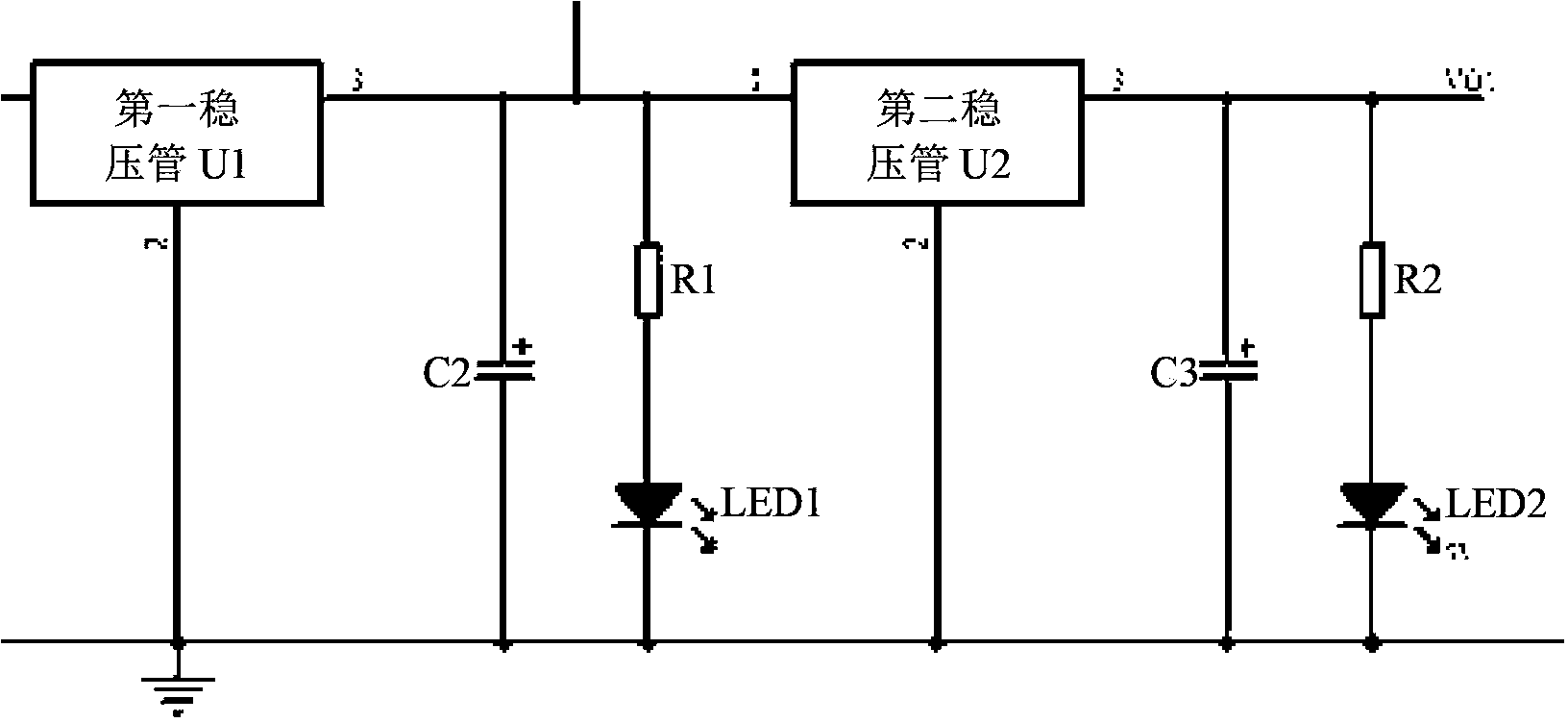

[0024] The energy harvesting module 4, the energy harvesting module 4 includes a first voltage regulator tube U1 and a second voltage regulator tube U2 connected in series, the first voltage regulator tube U1 converts the DC voltage from the power module 3 into a 12V voltage, The second voltage regulator tube U2 converts the 12V voltage from the first voltage regulator tube U1 into a 5V voltage. The first output end powered by the second diode D2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com