Fiber Optic Orientation Sensor for Partial Discharge Detection in High Voltage Electrical Equipment

A technology for partial discharge detection and high-voltage electrical equipment, which is applied in the field of sensors, can solve the problems of high sensor precision requirements, large influence of temperature changes, ultrasonic signal attenuation, etc., and achieve strong anti-interference ability, high sensitivity, and sensitive measurement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation will be described in detail below in conjunction with the accompanying drawings.

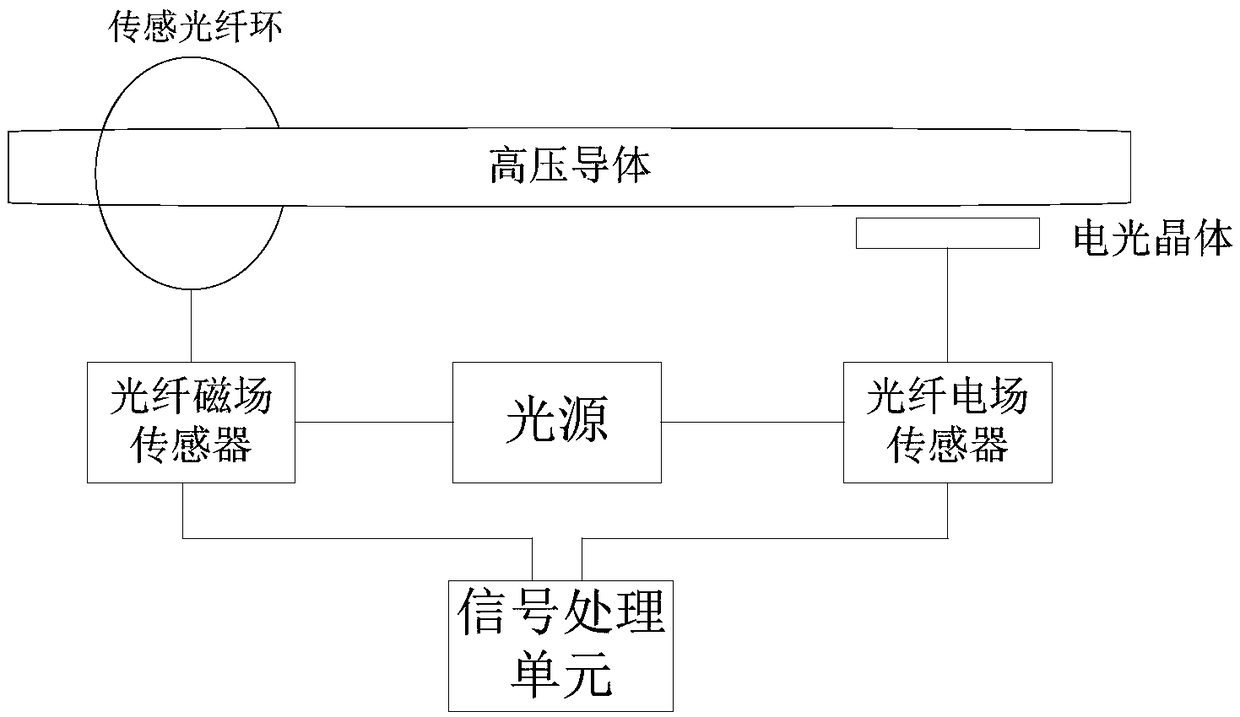

[0021] A fiber optic direction sensor for on-line partial discharge detection of high-voltage electrical equipment. The sensor system is composed of a fiber optic magnetic field sensor and a fiber optic electric field sensor. The propagation direction of the measured partial discharge signal is judged through joint detection.

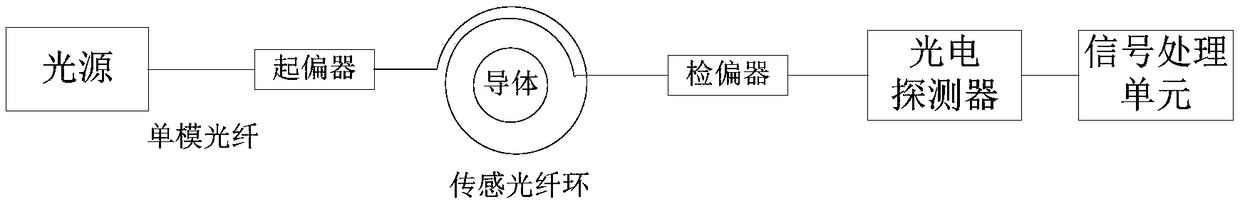

[0022] Fiber optic magnetic field sensors such as figure 1 As shown, it includes: a first single-mode optical fiber, a first polarizer, a sensing fiber ring, a first analyzer, and a first photodetector.

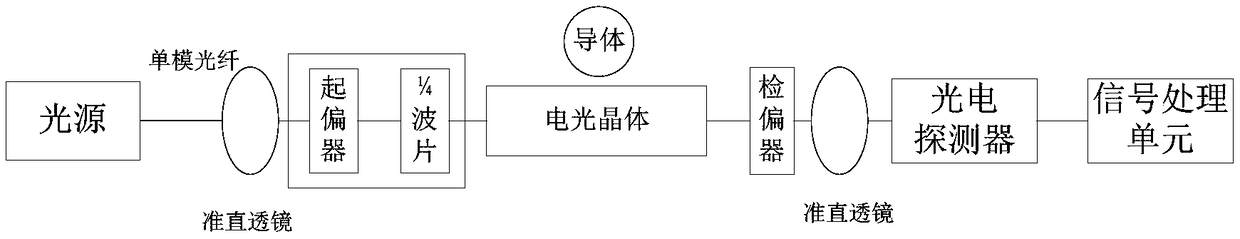

[0023] Fiber optic electric field sensors such as figure 2 As shown, it includes: the second single-mode fiber, the first collimating lens, the second polarizer, the quarter wave plate, the electro-optic crystal, the second analyzer, the second collimating lens, and the second photodetector .

[0024] Both the first single-mode fiber and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com