Electrochemiluminescence immunosensor for detecting beta-amyloid protein and construction of electrochemiluminescence immunosensor

A technology for amyloid and luminescent immunity, which is applied in the field of electrochemiluminescence immunosensors, can solve the problems of electrochemiluminescence immunosensors that do not see β-amyloid, and achieve ultra-sensitive detection, improve efficiency, and save reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Aβ Antibody-Nafion@Mesoporous Carbon-Ru(bpy) 3 2+ Preparation of nanocomposites

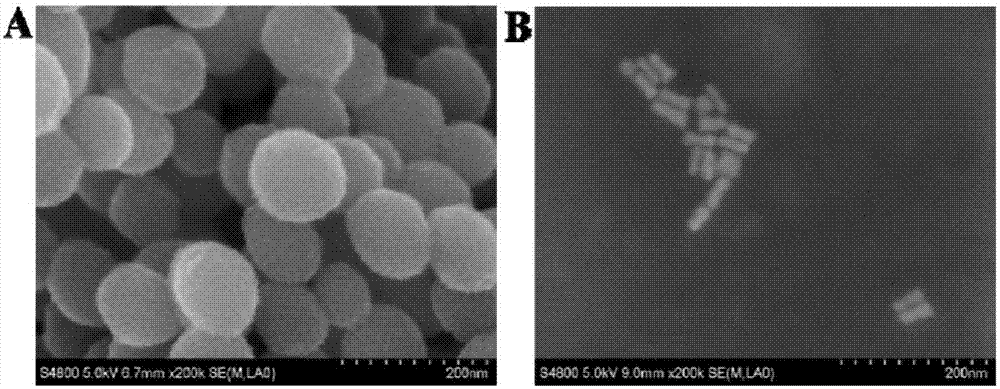

[0063] Firstly, Nafion@ mesoporous carbon-terpyridine ruthenium composite material was synthesized, and the process was as follows: 10 mg of mesoporous carbon (such as figure 1Shown in A) was dispersed in 5mL of 5wt% Nafion-ethanol mixed solvent, and stirred for 4 hours in an ice-water bath to obtain a Nafion-wrapped mesoporous carbon composite material. Nafion@ mesoporous carbon particles were obtained after centrifugation (12000rpm, 4°C), washed with PBS buffer solution, and dispersed in 2mL PBS for later use.

[0064] Under the condition of continuous stirring, 1mL 20mM ruthenium terpyridine solution was fully mixed with the above-mentioned Nafion@ mesoporous carbon composite material solution, stirred and reacted in an ice-water bath for 24 hours, centrifuged (12000rpm, 4°C) to remove excess unreacted substances, and the mesoporous carbon composite material was obtained. Pore car...

Embodiment 1-1

[0067] Firstly, Nafion@mesoporous carbon-terpyridine ruthenium composites were synthesized. The process was as follows: 10mg of mesoporous carbon was dispersed in 3mL of 3wt% Nafion-ethanol mixed solvent, and stirred for 3 hours in an ice-water bath to obtain Nafion-wrapped mesoporous carbon composites. Nafion@ mesoporous carbon particles were obtained after centrifugation (12000rpm, 4°C), washed with PBS buffer solution, and dispersed in 2mL PBS for later use.

[0068] Under continuous stirring conditions, fully mix 0.5mL 25mM ruthenium terpyridine solution with the above-mentioned Nafion@ mesoporous carbon composite material solution, stir and react in an ice-water bath for 18 hours, centrifuge (12000rpm, 4°C) to remove excess unreacted substances, and obtain Mesoporous Carbon@Ru(bpy) 3 2+ The composite material was washed with PBS buffer solution, dispersed in 2mL PBS and stored in the dark at 4°C for later use.

[0069] Add 500 μL of the above mesoporous carbon@Ru(bpy) ...

Embodiment 1-2

[0071] Firstly, the Nafion@mesoporous carbon-terpyridine ruthenium composite material was synthesized. The process was as follows: 10 mg of mesoporous carbon was dispersed in 7 mL of 7wt% Nafion-ethanol mixed solvent, and stirred for 4 hours in an ice-water bath to obtain Nafion-wrapped mesoporous carbon composites. Nafion@ mesoporous carbon particles were obtained after centrifugation (12000rpm, 4°C), washed with PBS buffer solution, and dispersed in 2mL PBS for later use.

[0072] Under the condition of continuous stirring, 2mL 15mM ruthenium terpyridine solution was fully mixed with the above-mentioned Nafion@ mesoporous carbon composite material solution, stirred and reacted in an ice-water bath for 24 hours, centrifuged (12000rpm, 4°C) to remove excess unreacted substances, and the mesoporous carbon composite material was obtained. Pore carbon @Ru(bpy) 3 2+ The composite material was washed with PBS buffer solution, dispersed in 2mL PBS and stored in the dark at 4°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com