Full-load molten salt steam generating system and control method thereof

A generation system and full-load technology, which is applied in steam generation methods using heat carriers, steam engine devices, heating devices, etc., can solve the problems that are not conducive to the economy of solar thermal power plants with heat storage, the reduction of available hours, molten salt Heat storage waste and other issues can be reduced to reduce the risk of solidification, avoid the temperature of molten salt being too low, and facilitate the control of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

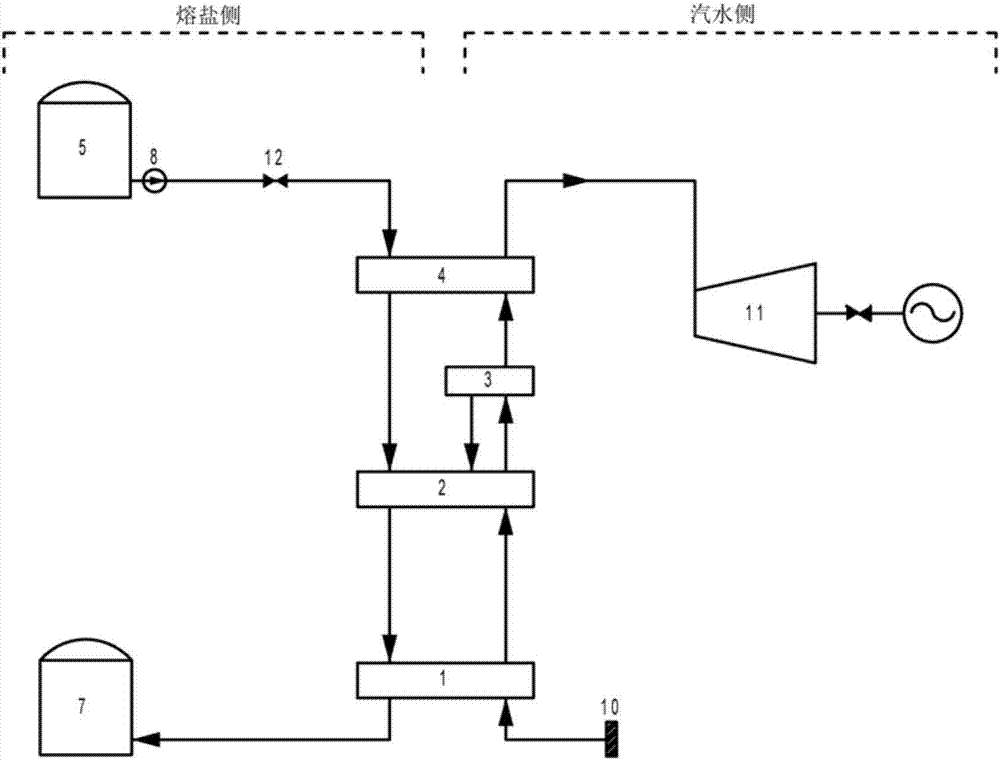

Method used

Image

Examples

Embodiment 1

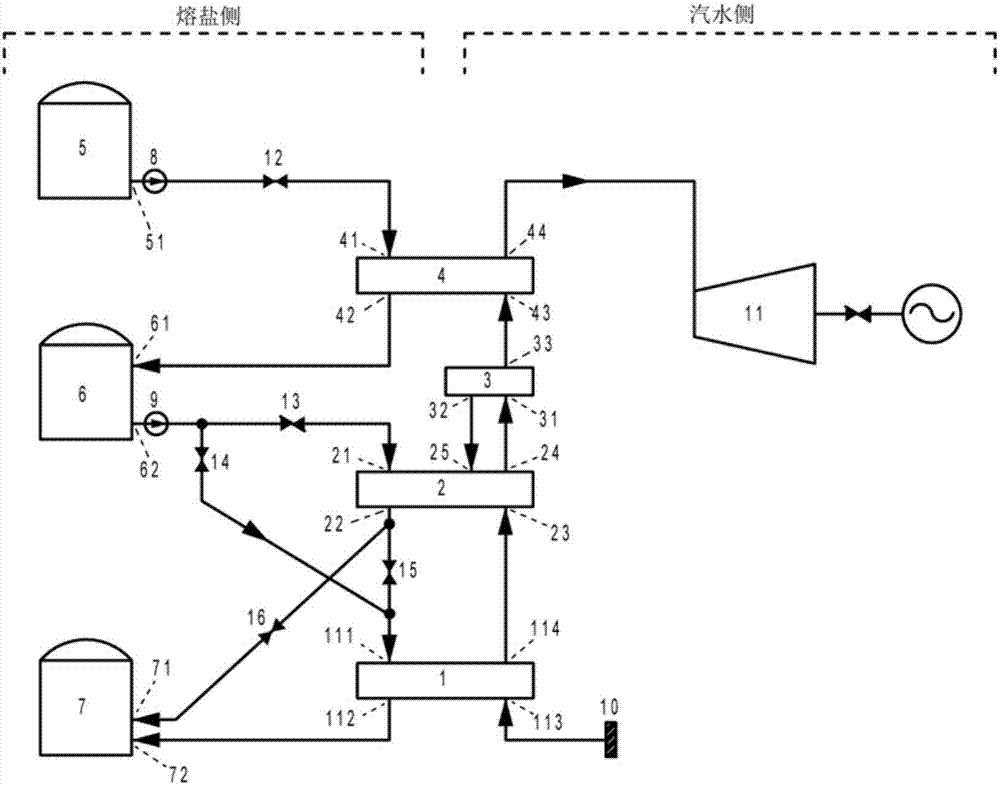

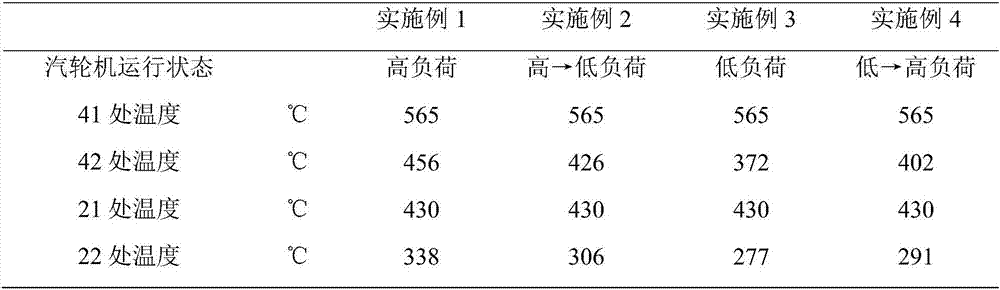

[0052] The steam turbine 11 is in high-load operation, and the hydraulic fluid with a pressure of 14Mpa and a temperature of 250°C enters the system from the hydraulic fluid inlet 10 of the system, and after continuous heat exchange with molten salt in the preheater 1, evaporator 2 and superheater 4 , the temperature of the superheated steam at the superheated steam outlet 44 of the superheater is 550°C. The temperature of the molten salt in the high-temperature molten salt tank 5 is 565°C. The high-temperature molten salt pump 8 draws the high-temperature molten salt from the high-temperature molten salt tank 5 and sends it to the superheater 4 for heat exchange with water vapor. Medium temperature molten salt tank 6. The second valve 13 and the fourth valve 15 are fully opened, and the third valve 14 and the fifth valve 16 are fully closed. The temperature of the molten salt in the medium-temperature molten salt tank 6 is 430°C. The medium-temperature molten salt pump 9 dra...

Embodiment 2

[0054] The steam turbine 11 is in the transition process from high load to low load. The hydraulic fluid with a pressure of 10Mpa and a temperature of 250°C enters the system from the hydraulic fluid inlet 10 of the system, and flows continuously in the preheater 1, evaporator 2 and superheater 4. After exchanging heat with the molten salt, the temperature of the superheated steam at the superheated steam outlet 44 of the superheater is 553°C. The temperature of the molten salt in the high-temperature molten salt tank 5 is 565°C. The high-temperature molten salt pump 8 draws the high-temperature molten salt from the high-temperature molten salt tank 5 and sends it to the superheater 4 for heat exchange with water vapor. Medium temperature molten salt tank 6. The opening degrees of the second valve 13 and the fourth valve 15 are reduced, the third valve 14 is opened, and the fifth valve 16 is fully closed. The temperature of the molten salt in the medium-temperature molten sal...

Embodiment 3

[0056] The steam turbine 11 is in low-load operation, and the hydraulic fluid with a pressure of 7Mpa and a temperature of 250°C enters the system from the hydraulic fluid inlet 10 of the system, and after continuous heat exchange with molten salt in the preheater 1, evaporator 2 and superheater 4 , the temperature of the superheated steam at the superheated steam outlet 44 of the superheater is 554°C. The temperature of the molten salt in the high-temperature molten salt tank 5 is 565°C. The high-temperature molten salt pump 8 draws the high-temperature molten salt from the high-temperature molten salt tank 5 and sends it to the superheater 4 for heat exchange with water vapor. Medium temperature molten salt tank 6. The opening degree of the second valve 13 decreases, the opening degree of the third valve 14 increases, the fourth valve 15 is fully closed, and the fifth valve 16 is opened. The temperature of the molten salt in the medium-temperature molten salt tank 6 is 430°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com