Preparation method and new application of aconite polysaccharide

A technology of aconite polysaccharide and use, applied in the field of aconite polysaccharide and its extraction and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

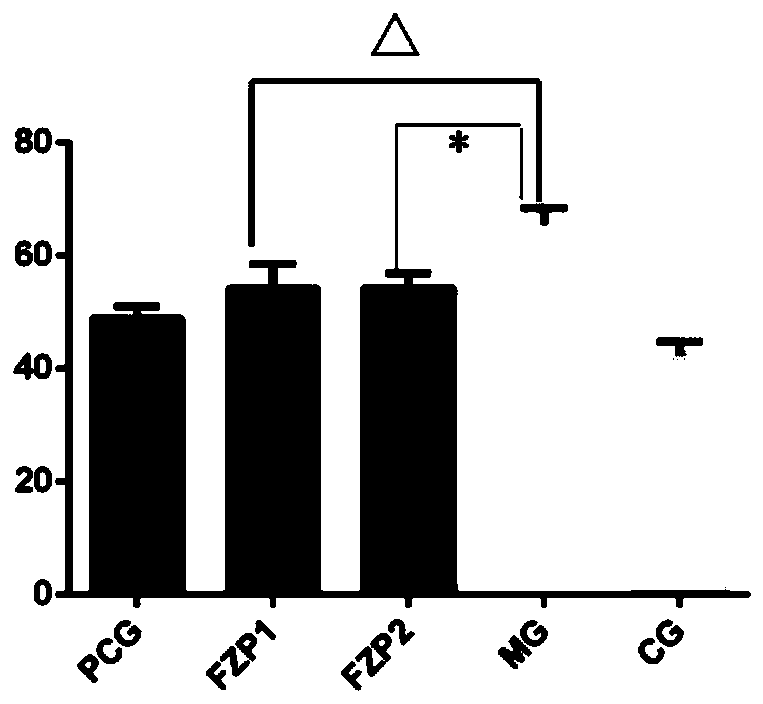

Examples

Embodiment 1

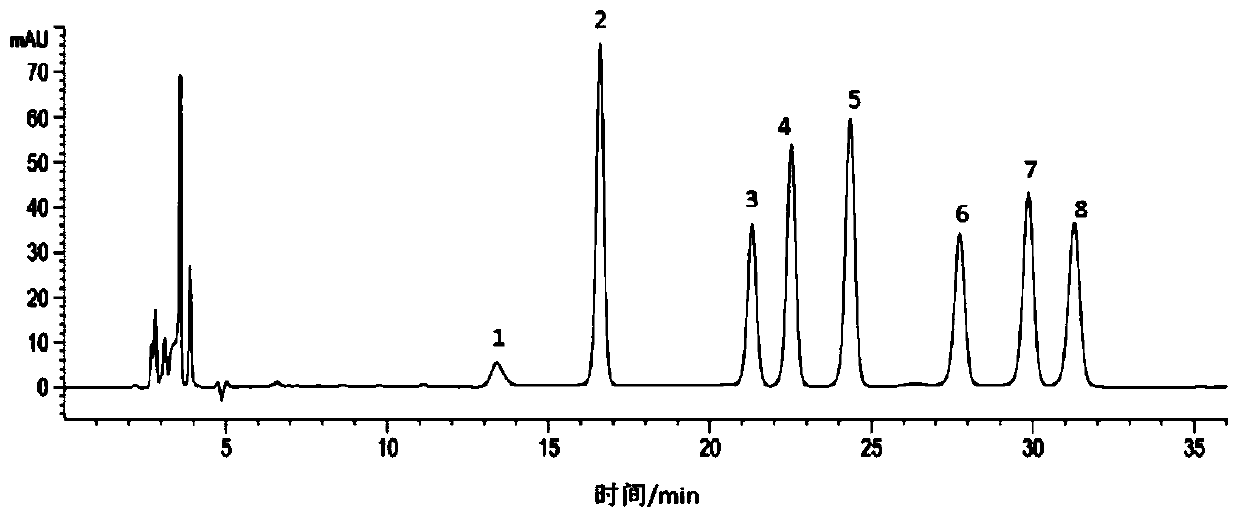

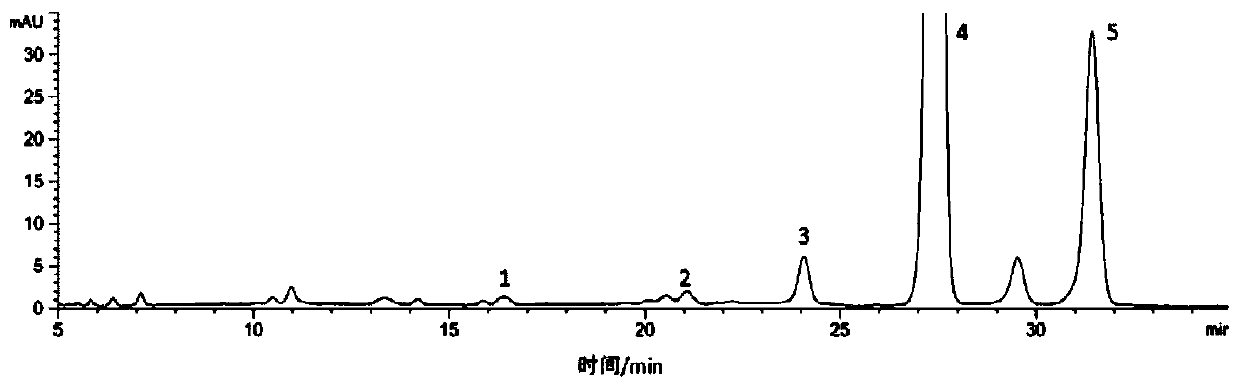

[0029] Example 1 Extraction and purification method of aconite polysaccharide of the present invention

[0030] (1) Degrease Sorting and removing impurities from the traditional Chinese medicine Fuzishengfu Tablets, crushed through a 20-mesh sieve with a mechanical pulverizer, took 100g, added 1000ml of 95% ethanol, and extracted at a temperature of 80°C for 3 hours, filtered, and the filter residue was evaporated to dryness naturally ethanol.

[0031] (2) Extraction Add 1500ml of purified water to the degreased filter residue at a temperature of 90°C, extract twice for 2 hours each time (solid-to-solid ratio 1:15), filter with four layers of gauze, and combine the filtrates twice.

[0032] (3) Concentration and alcohol precipitation The filtrate was concentrated under reduced pressure to 10% of the remaining solution, transferred to a beaker, cooled to room temperature, added 95% ethanol to make the final concentration of ethanol reach 65%, and stood in a refrigerator at 4°C ...

Embodiment 2

[0036] Embodiment 2 Extraction and purification method of aconite polysaccharide of the present invention

[0037] (2) Degrease Sorting and removing impurities from the traditional Chinese medicine Fuzi Heishun Tablets, crushed through a 20-mesh sieve with a mechanical pulverizer, took 100g, added 1500ml of 95% ethanol, and extracted at a temperature of 80°C for 3 hours, filtered, and the filter residue was evaporated to dryness naturally ethanol.

[0038] (2) Extraction Add 1500ml of purified water to the degreased filter residue at a temperature of 90°C, extract twice for 1 hour each time (solid-to-solid ratio 1:15), filter with four layers of gauze, and combine the filtrates twice.

[0039] (3) Concentration and alcohol precipitation The filtrate was concentrated under reduced pressure to 10% of the remaining solution, transferred to a beaker, cooled to room temperature, added 95% ethanol to make the final concentration of ethanol reach 75%, and stood in a refrigerator at 4...

Embodiment 3

[0043] Embodiment 3 Extraction and purification method of aconite polysaccharide of the present invention

[0044] (1) Degreasing Sorting and removing impurities from the traditional Chinese medicine Aconite Radix Aconitiae, crushing through a 30-mesh sieve with a mechanical pulverizer, taking 100g, adding 1800ml of 95% ethanol, extracting for 5 hours at a temperature of 80°C, and filtering to obtain a filter residue that volatilizes naturally. Dry ethanol.

[0045] (2) Extraction Add 2500ml of purified water to the degreased filter residue at a temperature of 90°C, extract twice for 2 hours each time (solid-to-solid ratio 1:25), filter with four layers of gauze, and combine the filtrates twice.

[0046](3) Concentration and alcohol precipitation The filtrate was concentrated under reduced pressure to 15% of the remaining solution, transferred to a beaker, cooled to room temperature, added 95% ethanol to make the final concentration of ethanol reach 80%, and stood in a refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com