A kind of synthetic method of α-acyl homoallyl sulfide compound

A technology of acyl homoallyl sulfide and thiol compounds, which is applied in the field of organic chemical synthesis, can solve the problems of restricting the practical application of known methods, environmental pollution caused by waste metal discharge, and increased reaction costs, achieving good application prospects and The effect of research value, no need for inert gas protection, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

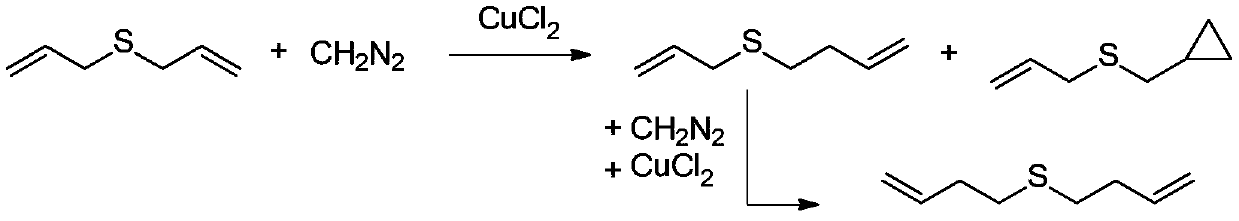

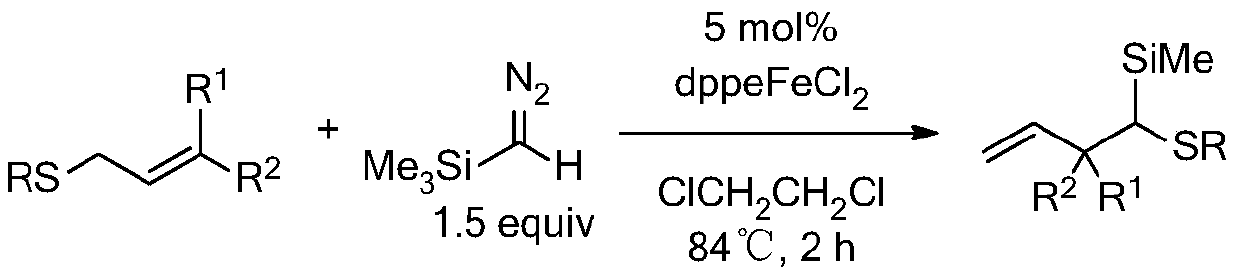

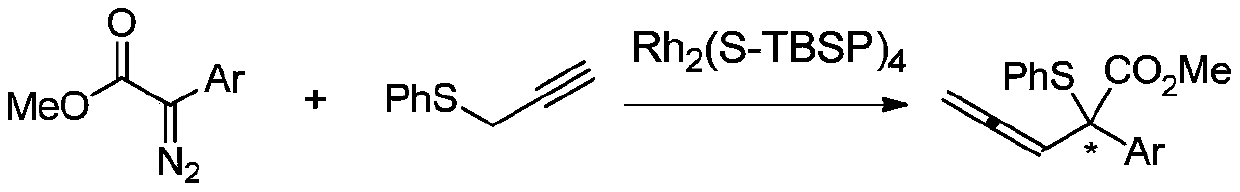

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the synthesis of compound IV-1

[0055]

[0056] Add 2-bromoacetophenone (39.8 mg, 0.2 mmol), thiophenol (0.6 mmol, 3 equiv.), allyl bromide (1.4 mmol, 7 equiv.) and Dipotassium hydrogen phosphate (1.0 mmol, 5 equiv.) was added to 1 mL of DMF, and the temperature was raised to 130° C. for 24 h.

[0057] After the reaction was complete, the reaction was quenched with 15 mL of saturated ammonium chloride solution, extracted with ethyl acetate (15 mL×3), and 3 The mixed organic phase was washed, then washed with 15 mL of saturated brine, dried over anhydrous sodium sulfate, and the solvent was removed under reduced pressure, and the residue was purified by flash column chromatography (petroleum ether / ethyl acetate volume ratio of 100:1) to obtain The target product was obtained with an isolation yield of 90%, and the product was a colorless oily liquid.

[0058] NMR: 1 H NMR (500MHz, CDCl 3 )δ7.83(d, J=7.5Hz, 2H), 7.46(t, J=7.3Hz, 1H), 7.34(t, J=7.5Hz,...

Embodiment 2

[0060] Embodiment 2: the synthesis of compound IV-2

[0061]

[0062] Add 2-bromo-p-methoxyacetophenone (45.8 mg, 0.2 mmol), thiophenol (0.6 mmol, 3 equiv.), allyl bromide (1.4 mmol, 7equiv.) and dipotassium hydrogen phosphate (1.0mmol, 5equiv.), add 1mL DMF, and raise the temperature to 130°C for 24h.

[0063] After the reaction was complete, the reaction was quenched with 15 mL of saturated ammonium chloride solution, extracted with ethyl acetate (15 mL×3), and 3 The mixed organic phase was washed, then washed with 15 mL of saturated brine, dried over anhydrous sodium sulfate, and the solvent was removed under reduced pressure, and the residue was purified by flash column chromatography (petroleum ether / ethyl acetate volume ratio of 100:1) to obtain The target product was obtained with an isolation yield of 84%, and the product was a colorless oily liquid.

[0064] NMR: 1 H NMR (500MHz, CDCl 3 )δ8.05-7.76 (m, 2H), 7.51-7.12 (m, 5H), 6.91 (d, J=8.9Hz, 2H), 5.91-5.83 (m...

Embodiment 3

[0066] Embodiment 3: the synthesis of compound IV-3

[0067]

[0068] Add 2-bromo-m-methylacetophenone (42.6mg, 0.2mmol), thiophenol (0.6mmol, 3equiv.), allyl bromide (1.4mmol, 7equiv. .) and dipotassium hydrogen phosphate (1.0 mmol, 5 equiv.), add 1 mL of DMF, heat up to 130 ° C for 24 h.

[0069] After the reaction was complete, the reaction was quenched with 15 mL of saturated ammonium chloride solution, extracted with ethyl acetate (15 mL×3), and 3 The mixed organic phase was washed, then washed with 15 mL of saturated brine, dried over anhydrous sodium sulfate, and the solvent was removed under reduced pressure, and the residue was purified by flash column chromatography (petroleum ether / ethyl acetate volume ratio of 100:1) to obtain The target product was obtained with an isolation yield of 82%, and the product was a colorless oily liquid.

[0070] NMR: 1 H NMR (500MHz, CDCl 3 )δ7.79-7.63 (m, 2H), 7.40-7.20 (m, 7H), 5.99-5.78 (m, 1H), 5.21-5.01 (m, 2H), 4.48 (t, J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com