Pulp for artificial sand dyeing and preparing method thereof

A kind of mortar material and artificial technology, applied in the field of architectural coatings, can solve the problems of VOC emission, good mechanical stability, low energy consumption, etc., and achieve the effect of low VOC emission and high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention also provides a preparation method for artificial sand dyeing slurry, which is used to prepare the artificial sand dyeing slurry according to the present invention, comprising the following steps:

[0034] Get each raw material and sand source of water-soluble acrylic acid amino glue according to the prescription that is used for artificially dyed sand slurry according to the present invention;

[0035] Preparation of water-soluble acrylic amino glue: Add the water-soluble acrylic resin of water-soluble acrylic amino glue into the dispersion tank, disperse and mix for 10-15 minutes, then add water, continue mixing for 10 minutes, add dispersant, anti-sedimentation agent, leveling agent and defoaming agent Add the agent into the dispersion cylinder, disperse for 10-20min at the speed of 500-1000rpm, then add rutile titanium dioxide and calcined kaolin, disperse at the speed of 2200-3000rpm until the fineness is less than or equal to...

Embodiment 1

[0043] This embodiment provides a slurry material for artificial dyeing sand, which is composed of water-soluble acrylic amino glue and sand source, in percentage by weight, water-soluble acrylic amino glue: 0.9%, sand source: 99.1%;

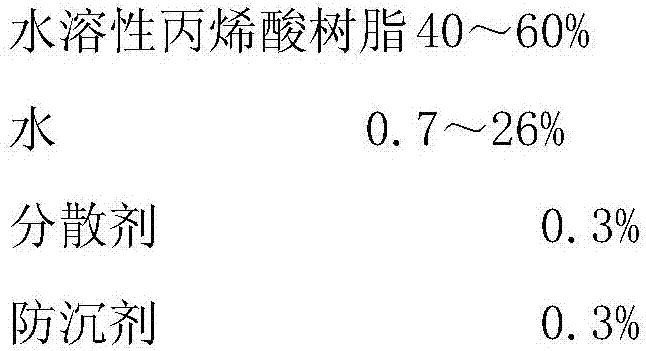

[0044] Among them, the water-soluble acrylic amino glue is composed of the following components by mass percentage:

[0045]

[0046]

[0047] The above-mentioned preparation method for artificially dyed sand slurry comprises the following steps:

[0048] Preparation of water-soluble acrylic amino glue: first add 60% water-soluble acrylic resin into the dispersion tank, disperse and mix for 10-15 minutes, then add water, continue mixing for 10 minutes, then add dispersant, anti-sedimentation agent, leveling agent, defoamer Put into the dispersion tank, disperse at 500-1000rpm for 10-20min, then add imported titanium dioxide, disperse calcined kaolin at 2200-3000rpm to fineness≤30μm, add amino resin, disperse at low speed 100-300rpm for 10m...

Embodiment 2

[0052] This embodiment provides a slurry material for artificial sand dyeing, which is composed of water-soluble acrylic amino glue and sand source, in percentage by weight, water-soluble acrylic amino glue: 3%, sand source: 97%;

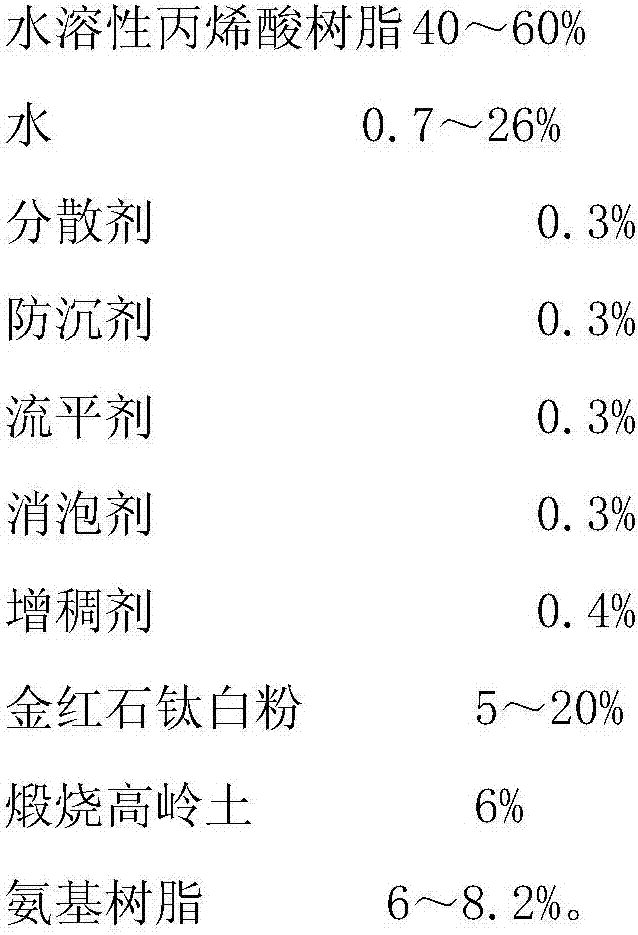

[0053] Among them, the water-soluble acrylic amino glue is composed of the following components by mass percentage:

[0054]

[0055] The above-mentioned preparation method for artificially dyed sand slurry comprises the following steps:

[0056]Preparation of water-soluble acrylic amino glue: first add 40% water-soluble acrylic acid to the dispersion tank, disperse and mix for 10-15 minutes, then add water, continue mixing for 10 minutes, then add dispersant, anti-sedimentation agent, leveling agent, defoamer to the In the dispersion cylinder, disperse at 500-1000rpm for 10-20min, then add imported titanium dioxide, disperse calcined kaolin at 2200-3000rpm until the fineness is ≤30μm, add 6% amino resin, disperse at a low speed of 100-300rpm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com