Variable-type roller structure for full-automatic cloth machine

A technology of roller structure and distributing machine, which is applied in the direction of thin material processing, winding, transportation and packaging, etc., and can solve the problems of equipment failure, irregular incision, towel tape cutting, and sewing processing that cannot be fully automated. and other issues, to achieve the effect of strong practicality and promotion value, and a simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

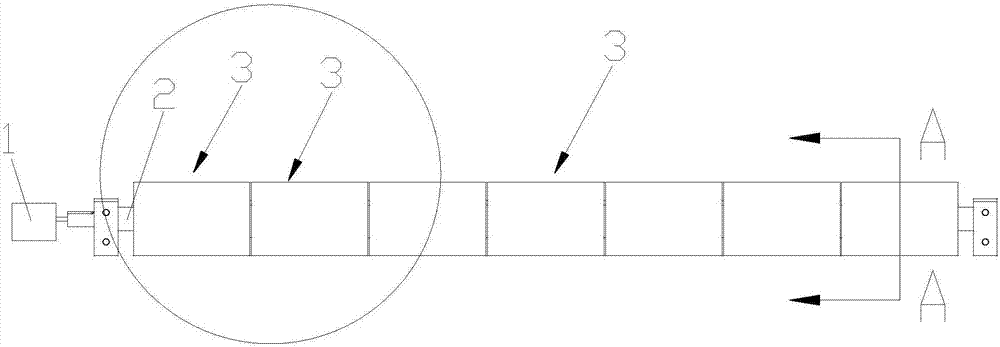

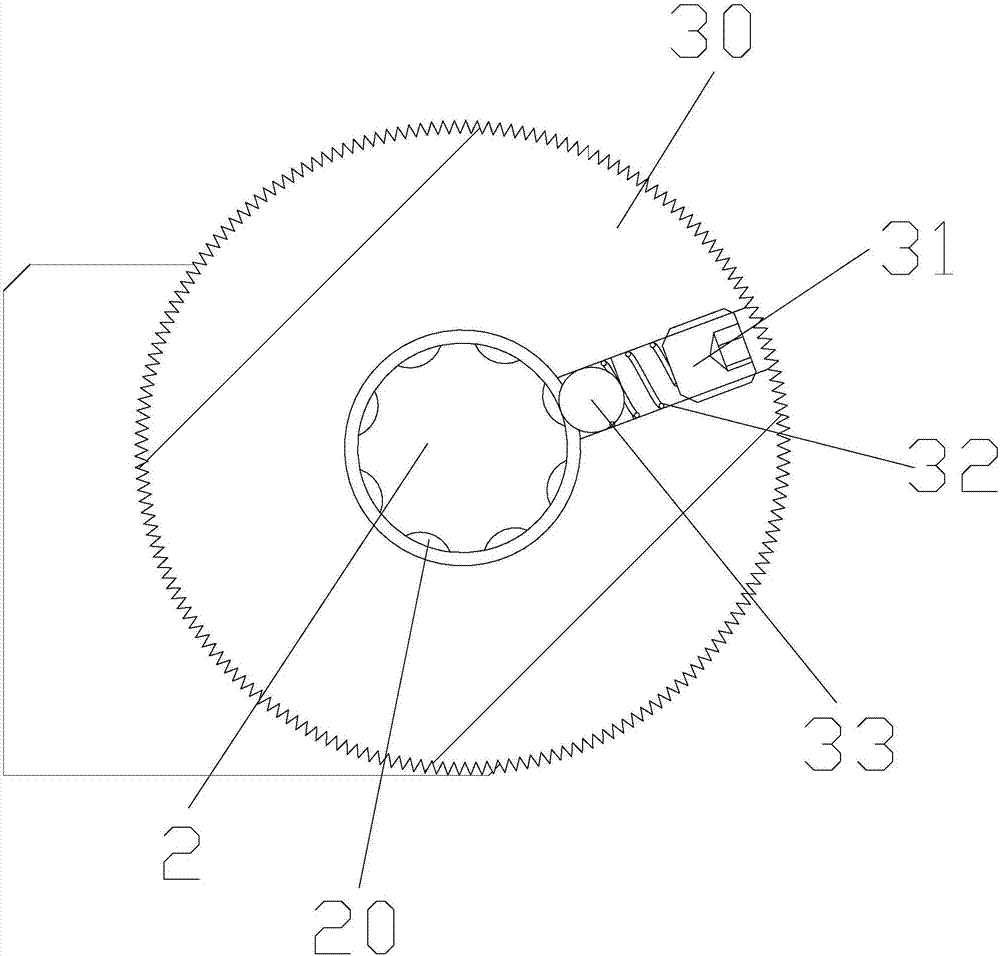

[0014] as attached Figure 1-3 The shown variable roller structure for a fully automatic distributing machine of the present invention includes a roller motor 1, a roller shaft 2 and a roller assembly 3; the roller motor 1 is connected to the roller shaft 2; the roller shaft 2 There are a plurality of grooves 20 along its circumferential direction; the roller shaft 2 is provided with a plurality of parallel roller assemblies 3; the roller assemblies 3 include rollers 30, fasteners 31, springs 32 and steel balls 33 There is a rotating shaft hole in the roller 30, and the above-mentioned roller shaft 2 is arranged in the rotating shaft hole; the fastener 31 is provided inside the roller 30; the fastener 31 is connected with the steel ball 33 through a spring 32, and the above-mentioned The other end of the steel ball 33 is clamped in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com