Parallel clamping device for clamping small components

A technology of parallel clamps and parts, applied in conveyor objects, transportation and packaging, metal processing, etc., can solve the problems of single assembly type, low clamping device accuracy, and inappropriate small assembly environment, and achieve smooth transition and design. Innovative ideas and high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

[0035] refer to Figure 1 to Figure 9 , a parallel clamping device for clamping small parts, including: a screw nut transmission part 1 used to transmit the motion of the servo motor, a transmission part 2 used to convert the nut rotation motion into the clamp parallel motion, and used to perform the output The clamping end and the flexible clamp part 3 as a control clamping force.

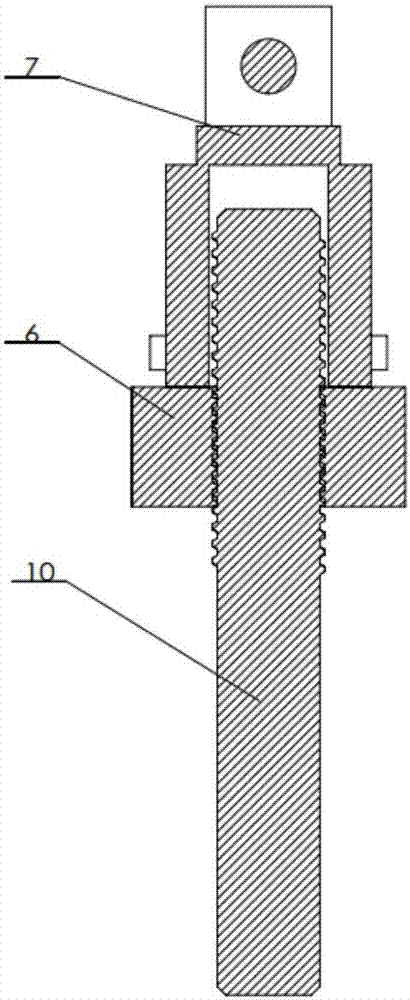

[0036] Wherein, the transmission part 1 includes: as image 3 As shown, the screw 10 is used to connect the servo motor. The screw 10 is connected to the nut 6 through threads. One end of the screw 10 is placed on the bearing seat 16 installed in the box body 1, and the nut 6 is in the chute inside the box body 1. The inside can only move up and down in parallel, so that the screw nut mechanism can work normally and with high precision in the absence of a bearing. There is a slot on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com