Cleaning system and method suitable for high-speed railway and bullet trains

A cleaning system and technology for high-speed rail trains, applied in vehicle cleaning, vehicle cleaning equipment, railway cleaning devices, etc., can solve the problems of polluted environment cleaning, incomplete cleaning, etc., and achieve the effects of improving efficiency, low heat accumulation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

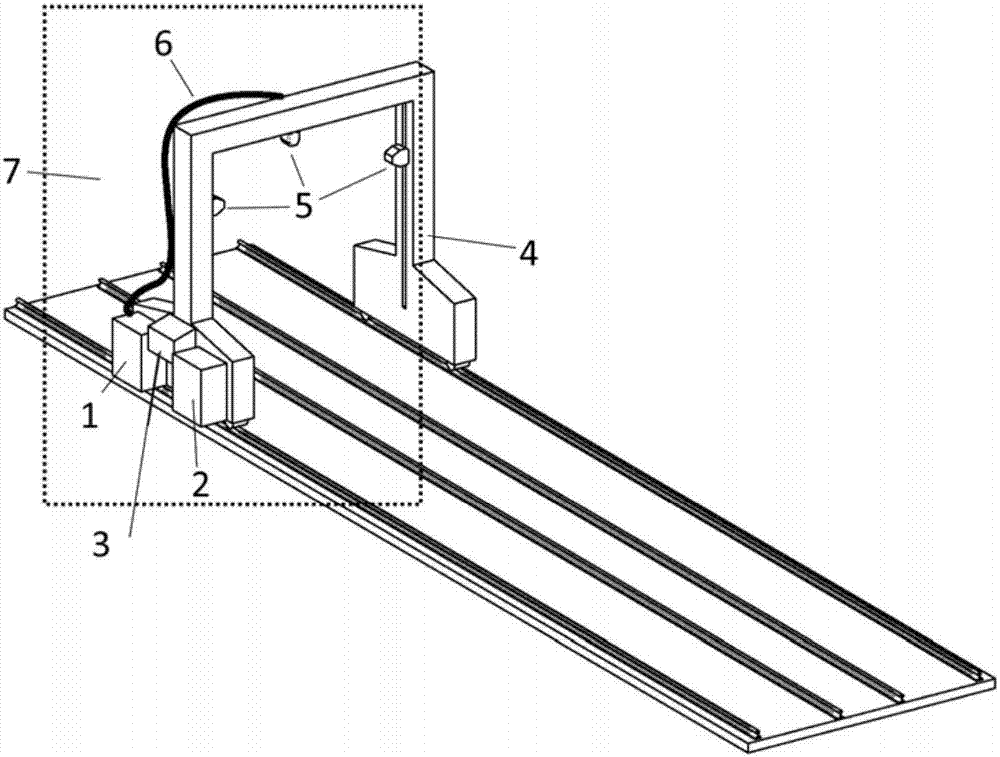

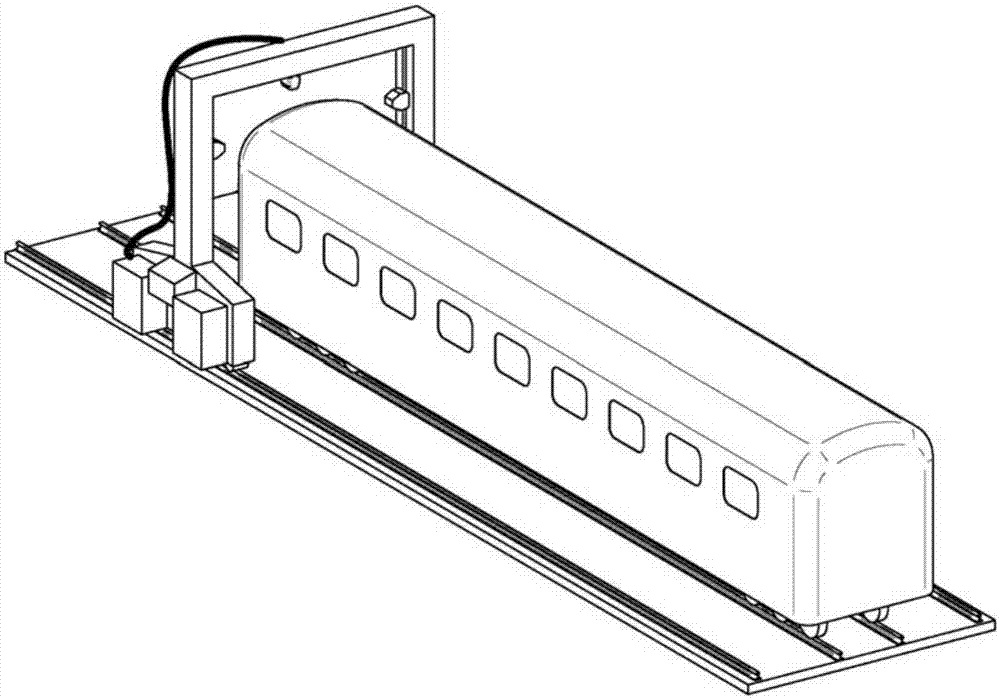

[0029] Such as figure 1 As shown, a cleaning system suitable for high-speed trains includes a mobile gantry 4, a central controller 3, and laser cleaning equipment 7. The bottoms of the two columns of the mobile gantry 4 are connected to the matching rails, and the mobile gantry 4 is perpendicular to the rails. , for the train to pass from below, the central controller 3 and the laser cleaning equipment 7 are connected to each other and fixed on the mobile gantry 4.

[0030] Laser cleaning equipment 7 comprises laser 1, water cooler 2 and optical output head 5, and central controller 3 is connected with laser 1 and optical output head 5 respectively by communication cable, and water cooler 2 is connected with laser 1 and optical output head 5 respectively, uses For cooling down, the optical output head 5 is installed inside the moving gantry 4 and connected to the laser 1 through the optical fiber 6 for cleaning the train body.

[0031] The optical output head 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com