Food material slicing production line and slicing method thereof

A production line and slicing technology, applied in metal processing and other directions, can solve the problems of high cost, poor versatility, and poor processing quality, and achieve the effect of short slicing process, continuous production, and improved efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment one, taking the production of potato chips as an example, specifically includes the following steps:

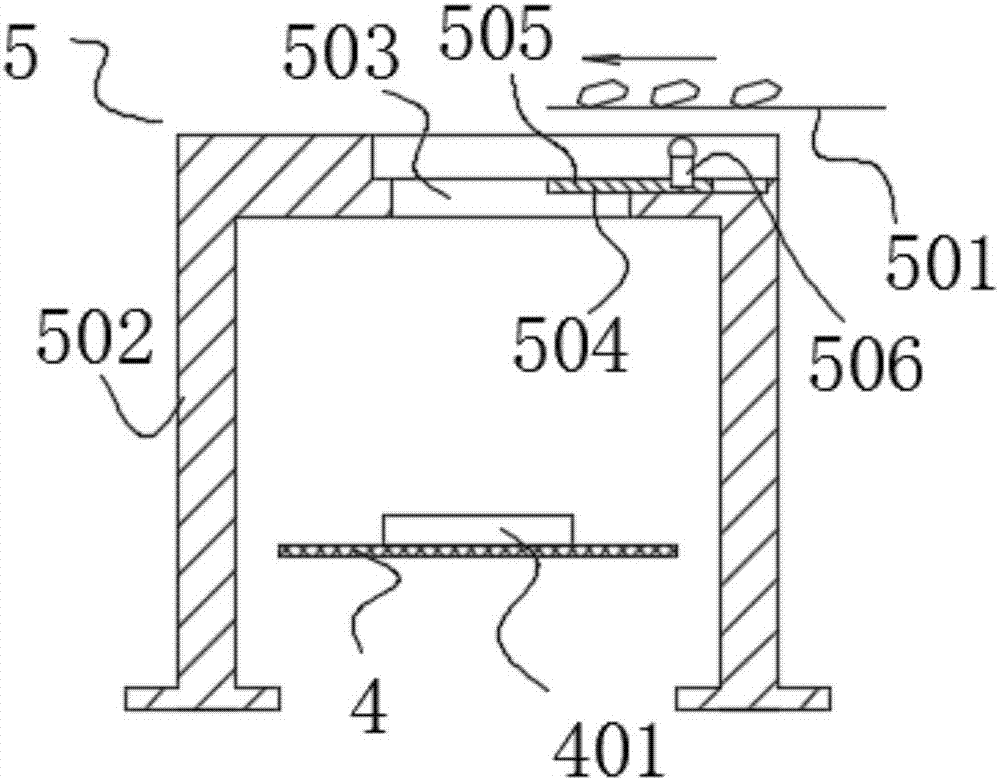

[0057] 1) Feeding: adjust the width of the feeding port 503 matched with the potatoes through the adjusting door on the second door-shaped support 502, and a single potato enters through the feeding port 503 and is placed on the cutting board 401;

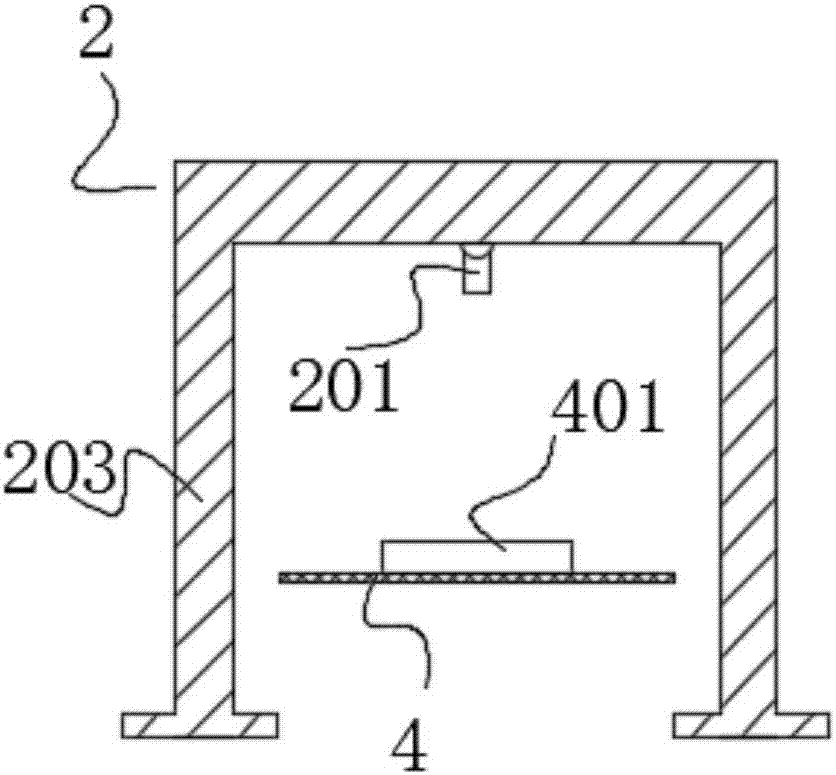

[0058] 2) Data acquisition and processing: Dynamically scan the moving potatoes through the dynamic scanner 201, the processor calculates the length and height of the potatoes, generates adjustment information for each solenoid valve, and also passes through the endless conveyor belt 4 The pulse movement time of the upper station rotation calculates the initial time and end time of pressing and slicing, and generates a slicing control program, and further generates a discharge control program;

[0059] 3) Slicing: Through the real-time monitoring of the moving potatoes by the camera 202, when the chopping board 4...

Embodiment 2

[0071] Embodiment two, taking the production of sweet potato chips as an example, comprises the following steps:

[0072] 1) Feeding: First, according to sweet potatoes of different specifications, adjust the width of the feed port 503 matching the sweet potatoes through the adjusting door on the second door-shaped bracket 502, and then the sweet potatoes enter through the feed port 503 and place them on the feeding mechanism 5 station on the cutting board 401;

[0073] 2) Data acquisition and processing: Dynamically scan the mobile sweet potato through the dynamic scanner 201, and the processor calculates the length and width of the sweet potato to generate adjustment information for the solenoid valve. The pulse movement time of the upper station rotation calculates the initial time and end time of pressing and slicing, and generates a slicing control program, and further generates a discharge control program;

[0074]3) Slicing: Through the real-time monitoring of the came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com