Collodion cotton material for mop and manufacturing method and mop with collodion cotton material

A manufacturing method and technology of collodion, applied in applications, household utensils, cleaning machinery, etc., can solve the problems of laborious mopping, dirt and water absorption capacity to be strengthened, and small compressible space, so as to achieve dirt and water absorption Increased capacity, large-area cleaning, and increased compressible space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

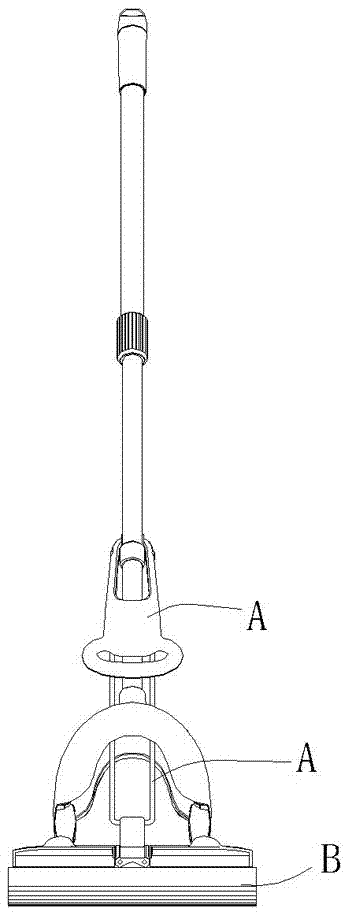

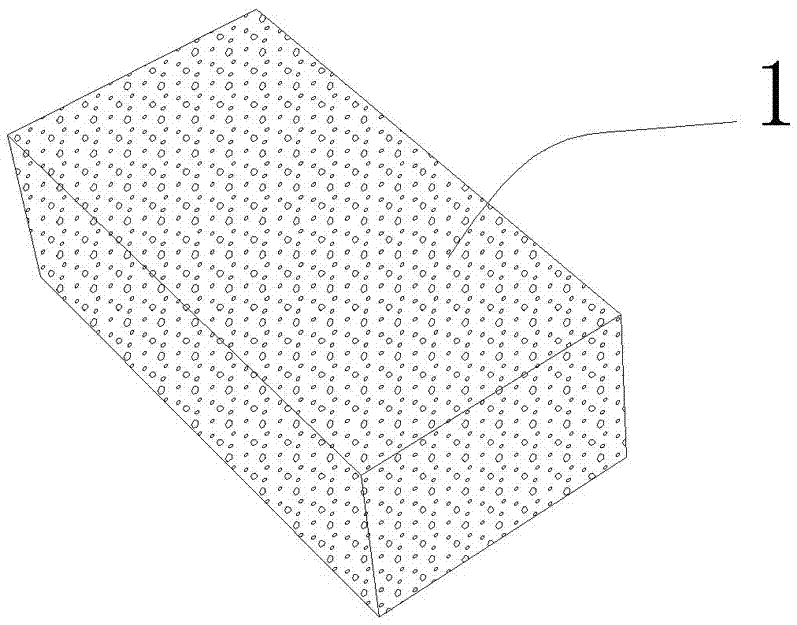

[0023] A novel PVA collodion material for a mop comprises a flexible skeleton and PVA collodion, the flexible skeleton has a porous structure, and the PVA collodion is filled in the porous structure of the flexible skeleton. The flexible skeleton described in the present embodiment selects PU sponge skeleton 1 for use, as figure 2 As shown, its porous structure is formed during the foaming process of PU sponge. Of course, the flexible skeleton can also use other materials, such as loofah, PE sponge with porous structure, other polyester sponges with porous structure, etc. The porous structure of loofah is the result of its own growth, PE sponge, other polyester sponges The porous structure can be formed in the process of self-foaming, or it can be formed by artificial drilling and other processing methods.

[0024] The above-mentioned manufacturing method of the novel PVA collodion material for mop is: prepare the PVA collodion slurry, prepare the flexible skeleton with poro...

Embodiment 2

[0032] The PVA collodion material used in the mop includes PVA collodion and flocculent flexible filling with a porous structure, and the flocculent flexible filler is filled in the PVA collodion. In this embodiment, the flocculent filling is PU sponge, and its porous structure is formed during the foaming process of the PU sponge. The so-called flocculent refers to the fragments formed after the PU sponge is shredded. The flocculent flexible filler refers to a cotton-like loose object with a regular or irregular hollow structure inside. Common flocculent flexible fillers, such as loofah, PE sponge with porous structure, other polyester sponges with porous structure, etc., are flocculent fragments formed after the above materials are shredded. The porous structure of loofah pulp is the result of its own growth. The porous structure of PE sponge and other polyester sponges can be formed in the process of self-foaming, or it can be formed by artificial drilling and other process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com