Processing method of kumquat tea

A processing method and technology of kumquat, which is applied in the field of food processing, can solve the problems of aging, appearance, color, aroma, and taste, etc., and achieve the effect of natural and fresh taste, soft and sweet taste, and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The processing method of kumquat tea comprises the following preparation steps:

[0026] 1) Select fresh and qualified kumquats and clean them;

[0027] 2) Open the cover of the washed kumquat, dig out the flesh of the kumquat, wash it, and dry the water in an oven at 35°C to obtain the kumquat shell;

[0028] 3) Put the dried kumquat husks into Pu'er ripe tea, cover the lid, and put the dried kumquat husks under the ultraviolet light with a radiation intensity of 140 μW / cm 2 Disinfect by ultraviolet lamp radiation for 30 minutes;

[0029] 4) Drying: first at -18°C, -90kPa, vacuum freeze-drying for 6h; then at 80W power, -70kPa vacuum, vacuum microwave drying for 50min; continue at -10°C, -98kPa, vacuum freeze-drying for 3h; Finally, under 40W power and -98kPa vacuum degree, vacuum microwave drying to constant weight;

[0030] 5) Leave it to room temperature and pack it.

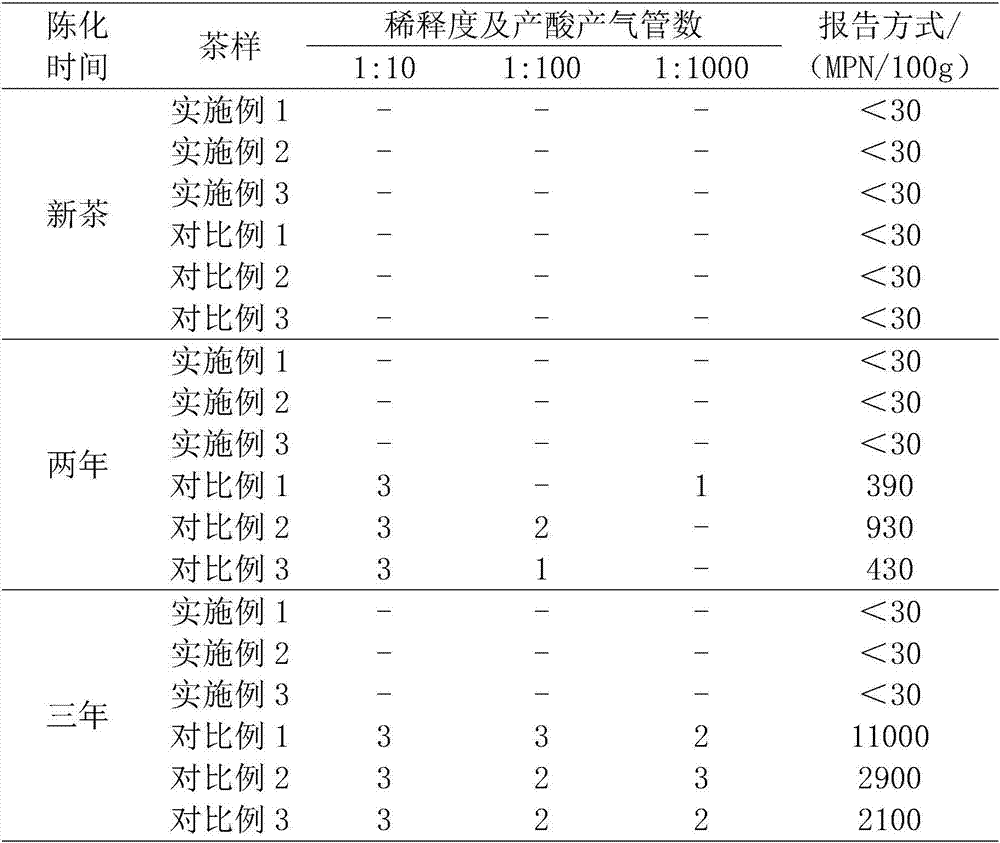

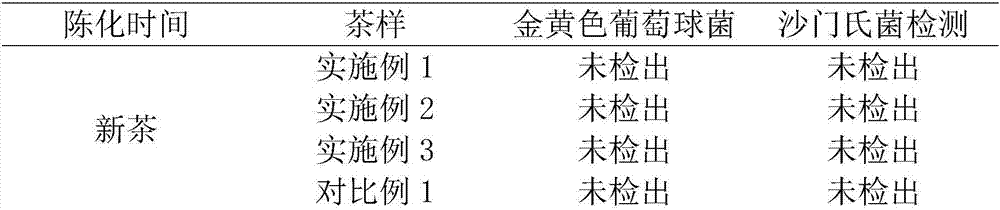

[0031] The surface of the kumquat tea in this embodiment has an oily luster. After the tea is ...

Embodiment 2

[0033] The processing method of kumquat tea comprises the following preparation steps:

[0034] 1) Select fresh and qualified kumquats and clean them;

[0035] 2) Open the cover of the washed kumquat, dig out the flesh of the kumquat, wash it, and dry the water in an oven at 38°C to obtain the kumquat shell;

[0036] 3) Put the dried kumquat husks into Pu'er ripe tea, cover the lid, and put the dried kumquat husks under the ultraviolet light with a radiation intensity of 120 μW / cm 2 Disinfect by ultraviolet lamp radiation for 35 minutes;

[0037] 4) Drying: first at -20°C, -85kPa, vacuum freeze-drying for 5h; then at 90W power, -85kPa vacuum, vacuum microwave drying for 60min; continue at -15°C, -98kPa, vacuum freeze-drying for 2h; Finally, under 50W power and -80kPa vacuum degree, vacuum microwave drying to constant weight;

[0038] 5) Leave it to room temperature and pack it.

[0039] The surface of the kumquat tea in this example has an oily luster. It has been aged for...

Embodiment 3

[0041] The processing method of kumquat tea comprises the following preparation steps:

[0042] 1) Select fresh and qualified kumquats and clean them;

[0043] 2) Open the cover of the washed kumquat, dig out the flesh of the kumquat, wash it, and dry the water in an oven at 40°C to obtain the kumquat shell;

[0044] 3) Put the dried kumquat husks into ripe Pu'er tea, cover with the lid, and put the dried kumquat husks under the ultraviolet light with a radiation intensity of 100 μW / cm 2 Disinfection with ultraviolet lamp radiation for 40 minutes;

[0045] 4) Drying: first at -25°C, -80kPa, vacuum freeze-drying for 3h; then at 100W power, -80kPa vacuum, vacuum microwave drying for 70min; continue at -18°C, -90kPa, vacuum freeze-drying for 1h; Finally, under 60W power and -80kPa vacuum degree, vacuum microwave drying to constant weight;

[0046] 5) Leave it to room temperature and pack it.

[0047] The surface of the kumquat tea in this example has an oily luster. It has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com