Spraying machine for plant protection

A technology for machinery and plant protection, which is applied in the device, application, animal husbandry and other directions of catching or killing insects. Complete, good effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

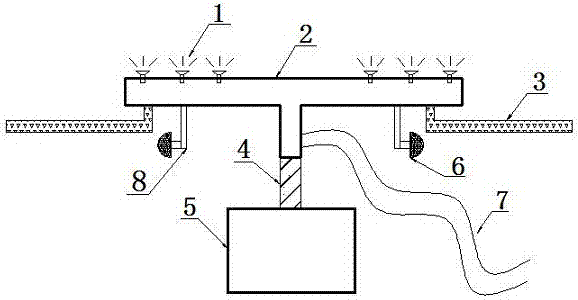

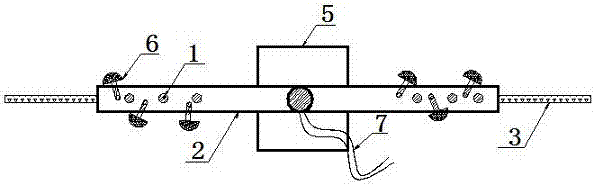

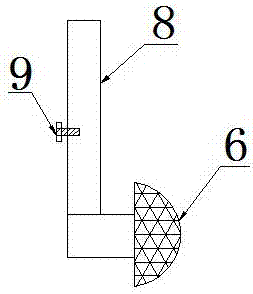

[0025] A plant protection machine for spraying, comprising a spray boom 2, a motor 5, a fan 6 and a hose 7, the spray boom 2 is in the shape of a "T", the spray boom 1 is a sealed hollow rod, and the spray boom 2 is grafted on the rotating shaft 4 of the motor 5 , the rotating shaft 4 extends from the inside of the motor 5, the rotating shaft 4 periodically changes the direction of rotation, the fan 6 is installed under the spray bar 2, and the fan 6 blows air along the horizontal divergent direction of the spray bar 1 rotation, and the connecting rod 8 of the fan 6 is a telescopic rod , the connecting rod 8 is provided with a screw fastener 9, the hose 7 is connected and communicated with the spray rod 2, the hose 7 is connected to the lower end of the vertical part of the "T"-shaped spray rod 2, and a spray head is arranged above the spray rod 2 1. Nozzle 1 is distributed at both ends of spray bar 2.

[0026] There are at least two fans 6 on the spray bar 2. When the number ...

Embodiment 2

[0033] A plant protection machine for spraying, comprising a spray boom 2, a motor 5, a fan 6 and a hose 7, the spray boom 2 is in the shape of a "T", the spray boom 1 is a sealed hollow rod, and the spray boom 2 is grafted on the rotating shaft 4 of the motor 5 , the rotating shaft 4 extends from the inside of the motor 5, the rotating shaft 4 periodically changes the direction of rotation, the fan 6 is installed under the spray bar 2, and the fan 6 blows air along the horizontal divergent direction of the spray bar 1 rotation, and the connecting rod 8 of the fan 6 is a telescopic rod , the connecting rod 8 is provided with a screw fastener 9, the hose 7 is connected and communicated with the spray rod 2, the hose 7 is connected to the lower end of the vertical part of the "T"-shaped spray rod 2, and a spray head is arranged above the spray rod 2 1. Nozzle 1 is distributed at both ends of spray bar 2.

[0034] The spray boom 2 is made of aluminum alloy material, which can gre...

Embodiment 3

[0041] A plant protection machine for spraying, comprising a spray boom 2, a motor 5, a fan 6 and a hose 7, the spray boom 2 is in the shape of a "T", the spray boom 1 is a sealed hollow rod, and the spray boom 2 is grafted on the rotating shaft 4 of the motor 5 , the rotating shaft 4 extends from the inside of the motor 5, the rotating shaft 4 periodically changes the direction of rotation, the fan 6 is installed under the spray bar 2, and the fan 6 blows air along the horizontal divergent direction of the spray bar 1 rotation, and the connecting rod 8 of the fan 6 is a telescopic rod , the connecting rod 8 is provided with a screw fastener 9, the hose 7 is connected and communicated with the spray rod 2, the hose 7 is connected to the lower end of the vertical part of the "T"-shaped spray rod 2, and a spray head is arranged above the spray rod 2 1. Nozzle 1 is distributed at both ends of spray bar 2.

[0042] The spray boom 2 is made of aluminum alloy material, which can gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com