A high-brightness wide viewing angle brightness-enhancing film

A brightness-enhancing film and wide-viewing-angle technology, applied in instruments, optics, prisms, etc., can solve problems such as small viewing angles and insufficient brightness of large-size displays, and achieve the effects of serious energy consumption, high scratch resistance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

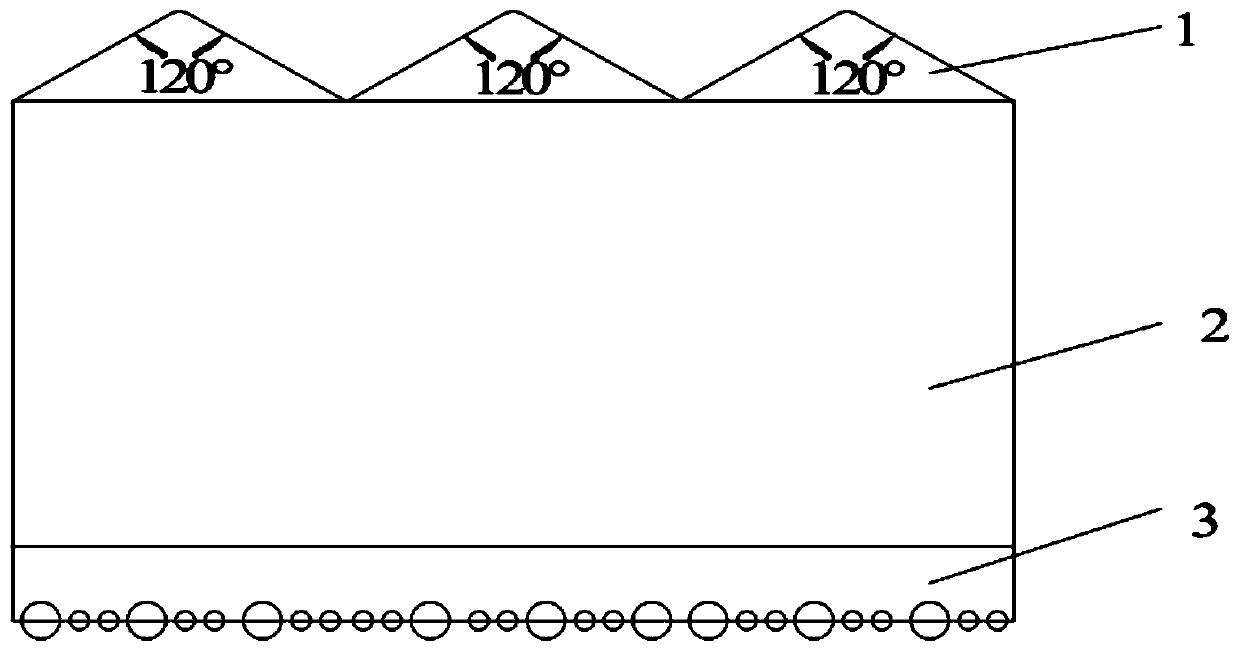

[0052] The preparation method of the high-brightness wide viewing angle brightness enhancement film provided by the present invention comprises the following steps:

[0053] (1) Mix solvent-free UV-curable polyester acrylic resin glue and inorganic oxide particles evenly;

[0054] (2) coating the mixture obtained in step (1) on one surface of the substrate layer by means of a structural stick, embossing the microstructure, and curing the microstructure under UV light to obtain a prism structure layer;

[0055] (3) Mix solvent-based UV-curable resin glue, acrylic particles and solvents to prepare a back coating solution;

[0056] (4) Coating the back coating liquid on the other surface of the substrate layer by an anilox roller, and curing the back coating under UV light after baking in an oven.

[0057] The test method of the brightness enhancing film provided by the invention is as follows:

[0058] 1. Brightness enhancement film luminance: BM-7A luminance meter is used, an...

Embodiment 1

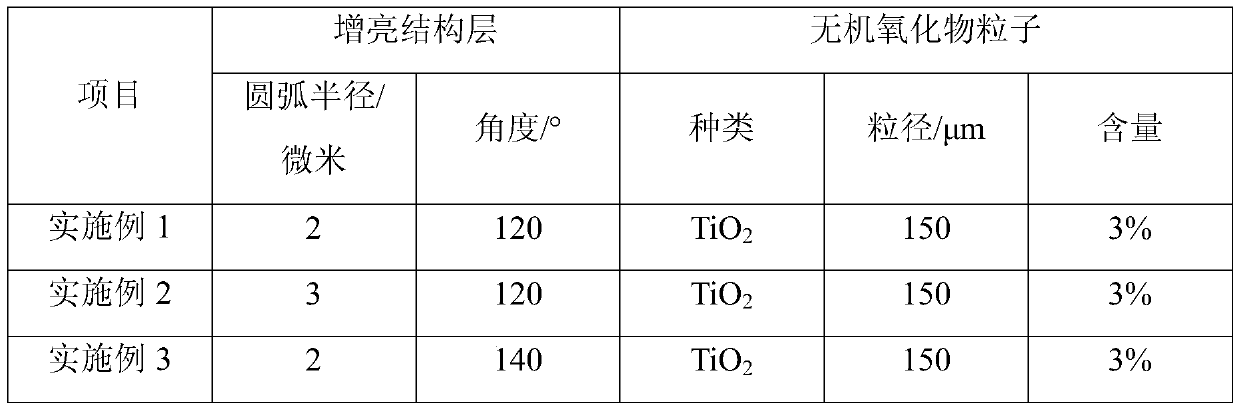

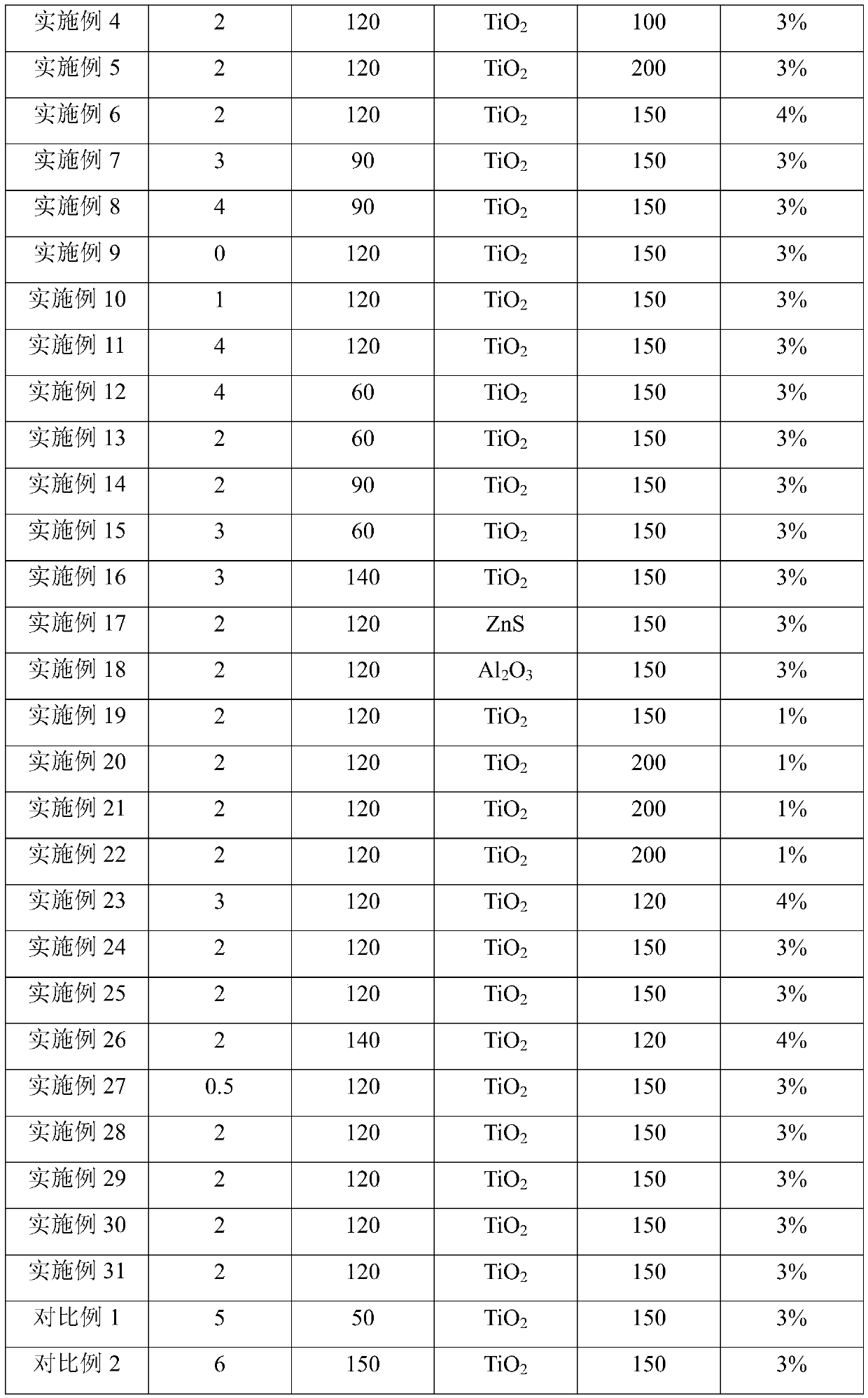

[0062] The invention provides a high-brightness and wide-angle brightness enhancement film, wherein the brightness enhancement film comprises a brightness enhancement structure layer, a base material layer and a back coating in sequence; the brightness enhancement structure layer is a prism structure, and the transverse width of the prism structure The cross section is an isosceles triangle, and the top angle of the isosceles triangle is a circular arc. Among them, the height of the isosceles triangle is 25 μm, the apex angle of the isosceles triangle is 120°, and the radius of the arc is 2 μm; the brightening structure layer includes inorganic oxide particles TiO 2 ,TiO 2 The particle size is 150nm, and its content is 3% of the polyester acrylic resin. The substrate layer is PET with a thickness of 188um. The back coating includes 19% of solvent-based UV-curable acrylic resin glue, 1% of acrylic (polymethyl methacrylate) particles, the particle size of acrylic particles is ...

Embodiment 2

[0064] Brightness enhancing film as provided in Example 1. Among them, the height of the isosceles triangle is 25 μm, the apex angle of the isosceles triangle is 120°, and the arc radius is 3 μm; the brightening structure layer includes inorganic oxide particles TiO 2 ,TiO 2 The particle size is 150nm, and its content is 3% of the polyester acrylic resin. The substrate layer is PET with a thickness of 188um. The back coating includes 19% of solvent-based UV-curable acrylic resin glue, 1% of acrylic (polymethyl methacrylate) particles, the particle size of acrylic particles is 5 μm, and 80% of solvents, including butanone, toluene, propylene glycol methyl ether, The mass ratio is 1:1:2, and the mixed back coating is coated on the substrate layer by an anilox roller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com