A kind of extruded diffusion film and preparation method thereof

A diffusion film and extrusion type technology, applied in the field of diffusion film, can solve the problems of harming the environment and human health, complex production process of coating diffusion film, etc., to improve environmental health, simple and convenient production process, high light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

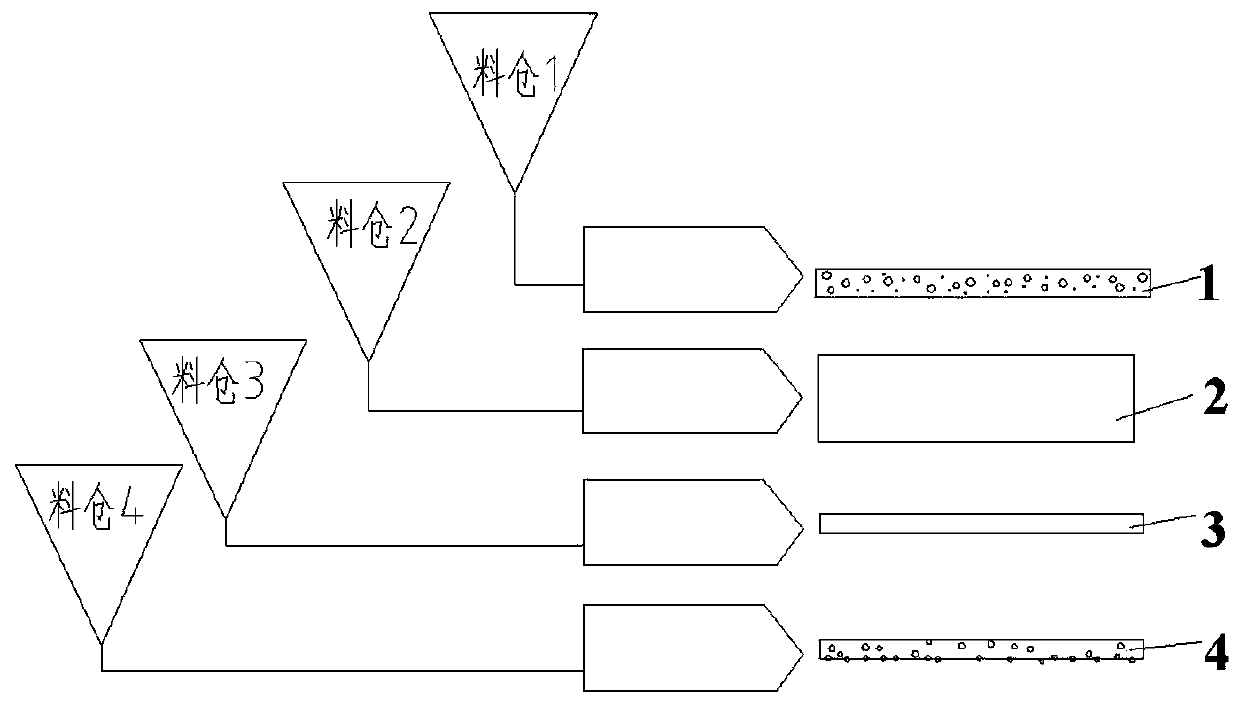

[0046] Such as figure 2 Shown, the present invention provides a kind of preparation method of extruded diffusion membrane, described method comprises the following steps:

[0047] (1) The four-layer co-extrusion of the extruder simultaneously extrudes the diffusion A layer, base film B layer, base film C layer, and diffusion D layer; after the four layers are extruded at the same time, they reach the cooling roll by casting, and then pass through Two-way stretch;

[0048] (2) Forming the diffusion film after cooling and forming.

[0049] The test method of the main performance of the diffusion membrane provided by the invention is briefly described as follows:

[0050] (1) The light transmittance and haze of the diffuser film are measured by HunterLab UltraScan PRO ultra-high-precision spectrophotometer, and the test conditions are carried out in accordance with the national standard GB2410-1980. And the implementation of haze and light transmittance: haze ≥ 84%, light tra...

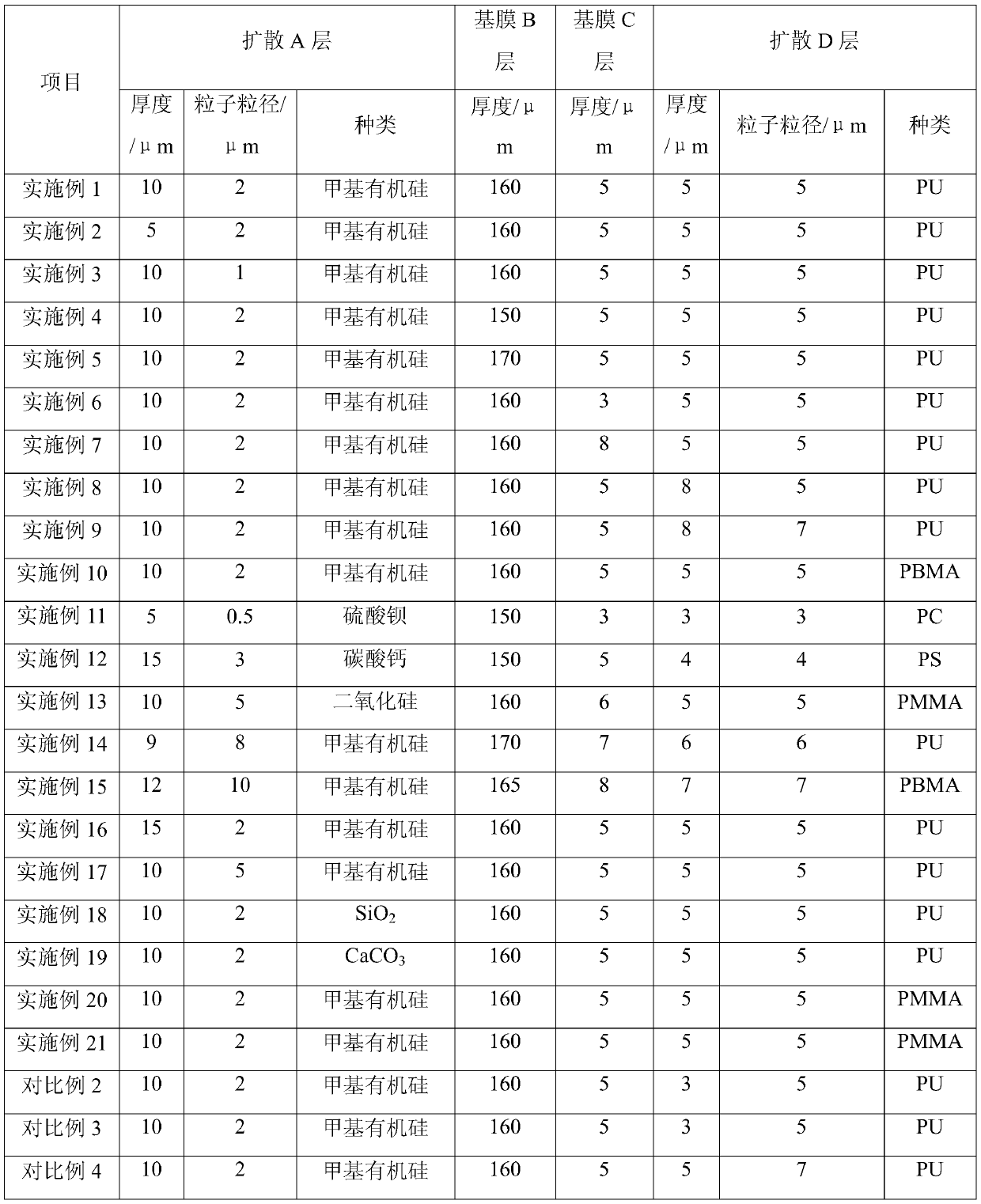

Embodiment 1

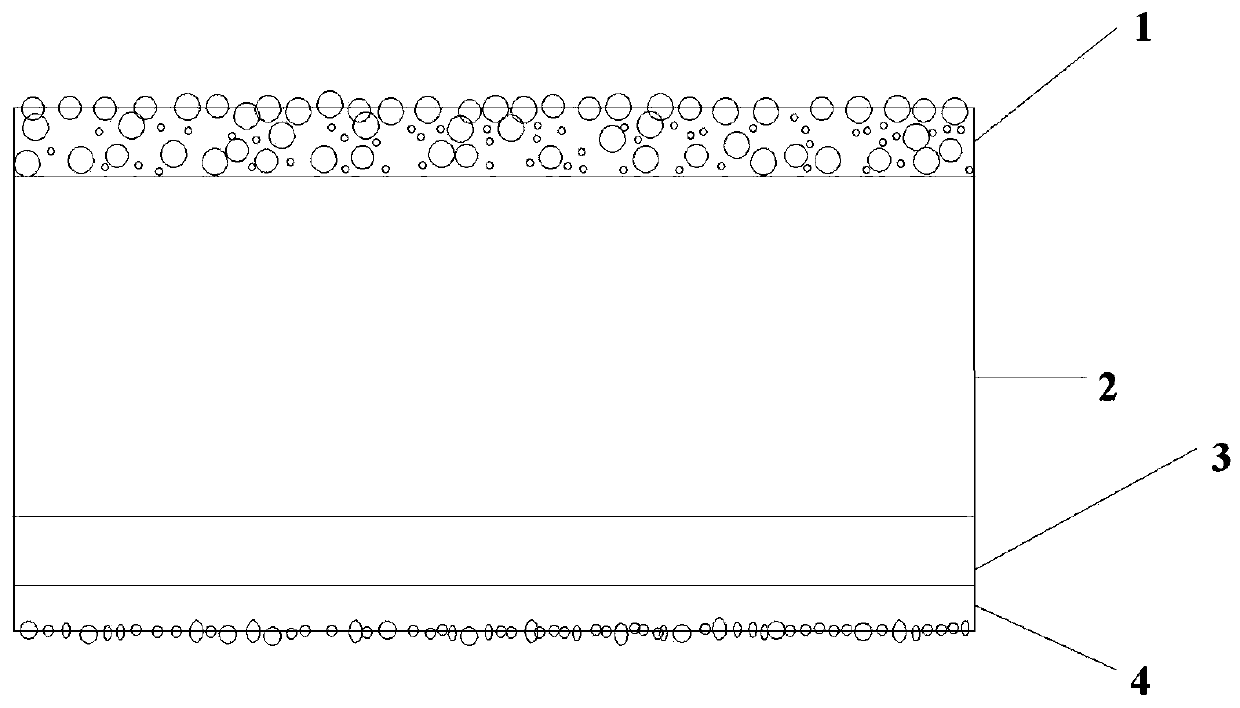

[0056] The invention provides an extruded diffusion film. The diffusion film is sequentially composed of a diffusion A layer, a base film B layer, a base film C layer, and a diffusion D layer. The diffusion A layer and the diffusion D layer are respectively located on the base film Layer B and the outer side of layer C of the base film; the diffusion film is a four-layer co-extruded structure. The diffusion A layer includes diffusion particles and PET, the diffusion D layer includes diffusion particles and PET, and the diffusion particles and PET are mixed and then extruded to form the diffusion A layer and the diffusion D layer. It is co-extruded by four layers of extruder, then cast onto the cooling roll, stretched by cast sheet, and finally cooled and formed to form an extruded diffusion film.

[0057] Wherein, the thickness of the diffusion A layer is 10 μm, the diffusion particles of the diffusion A layer are methyl silicone, the particle diameter of the diffusion particl...

Embodiment 2

[0059] The extruded diffusion film as described in Example 1, wherein the thickness of the diffusion A layer is 5 μm, the diffusion particles of the diffusion A layer are methyl silicone, the particle size of the diffusion A layer is 2 μm, and the proportion is PET. 40%. The B layer of the base film is PET with a thickness of 160 μm, and the C layer of the base film is PET with a thickness of 5 μm. The thickness of the diffusion D layer is 5 μm, the diffusion particles of the diffusion D layer are PU, the particle diameter of the diffusion D layer is 5 μm, and the proportion is 50% of PET.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com