High-sensitivity photoelectric level detection device

A technology of level detection and high sensitivity, applied in the fields of sensing technology, optoelectronic technology and mechanical technology, it can solve the problems of low sensitivity and resolution, high requirements for level detection and automatic level adjustment, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

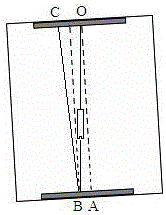

[0006] The invention comprises a dark box (1), a flat mirror (2), a PSD photoelectric sensor (3), a filament (4), and a laser (5). A flat mirror (2) is fixed on the bottom of the dark box (1), a PSD photoelectric sensor (3) is fixed on the upper bottom, and the laser (5) is suspended at the center of the upper bottom of the dark box (1) by a filament (4). The laser (5) It can swing around point O in a vertical plane. The obscura (1) is in the shape of a cuboid, and the inner wall becomes black, which is opaque and does not reflect light; the plane mirror (2) is in a rectangular shape. The PSD photoelectric sensor (3) adopts the model BOS-PSD0018, which converts light displacement into current change. The upper end of the filament (4) is fixed at the center of the upper bottom surface of the dark box (1), and the lower end hangs the laser (5); the light from the laser (5) shoots down to the plane mirror (2), and is reflected by the plane mirror (2) to the PSD photoelectric sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com