A kind of bridge structure reinforcement mould and reinforcement method

A bridge structure and mold technology, applied in bridge reinforcement, bridge, bridge construction, etc., can solve problems such as poor corrosion resistance, increase concrete thickness, difficulty in estimating bearing capacity, etc. Stress loss, reducing the effect of long-term relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

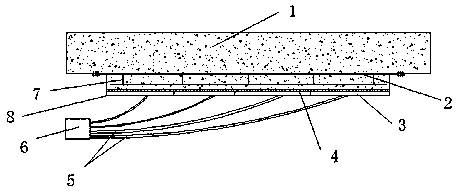

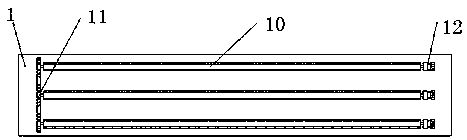

[0033] see Figure 1 to Figure 5 , a bridge structure reinforcement mold 10, the reinforcement mold 10 includes a U-shaped formwork 8, a top plate 4, an inflatable cushion 3 and an air pump 6, several inflatable cushions 3 are arranged on the bottom plate in the U-shaped formwork 8, and each inflatable The pad 3 is connected to the air pump 6 through the air pipe. The top plate 4 is made of a material with high rigidity and is easy to demould from the concrete. In this embodiment, high-hardness plastic is used to ensure that no large deformation occurs after the concrete is poured in; the top plate 4 Placed on the inflatable cushion 3, the bottom plate of the U-shaped formwork 8 is provided with a number of inflatable air pipes 5 through holes, and the top plate 4 is also provided with a heating sheet. The U-shaped formwork 8 is fixed on the bottom surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com