SBS grafted odor-removing mattress spraying glue and preparation method thereof

A deodorizing, mattress technology, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the problems of reduced adhesive strength, residual odor, powdering, etc., to reduce the number of double chains, The effect of improving the bonding strength and improving the adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of SBS graft type net smell mattress spray glue, comprises the component of following weight part:

[0026] 10-15 parts of methyl isobutyl ketone;

[0027] 5-10 parts of isopropyl formate;

[0028] 10-20 parts of aromatic environment-friendly solvent oil;

[0029] 15-25 parts of methylcyclohexane;

[0030] 10-18 parts of SBS elastomer;

[0031] BPO 0.1~0.5 parts;

[0032] 5-15 servings of MMA;

[0033] BA 0~8 copies;

[0034] 2-HEMA 0~3 parts;

[0035] 1 to 3 parts of terminator;

[0036] 10-15 parts of hydrogenated petroleum resin;

[0037] 12-18 parts of hydrogenated rosin modified resin.

[0038] As a preferred embodiment, in the present embodiment, the SBS graft type net odor mattress spray glue, the parts by weight of each component are:

[0039] 10 parts of methyl isobutyl ketone;

[0040] 6 parts of isopropyl formate;

[0041] 12 parts of aromatic environment-friendly solvent oil;

[0042] 18 parts of methylcyclohexane;

[0043] 15 parts of S...

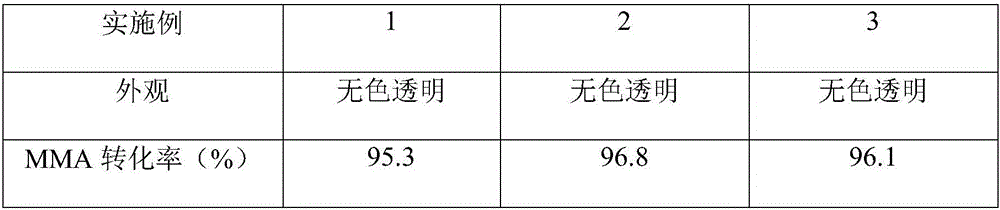

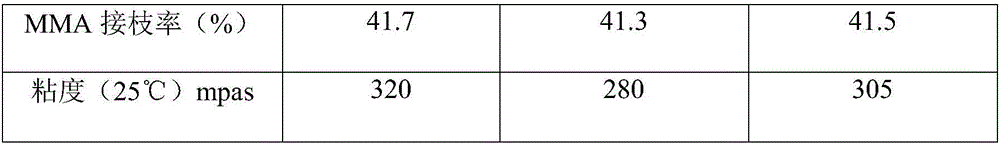

Embodiment 2

[0070] By the method described in embodiment one, produce SBS grafting type clean smell mattress spray glue, difference is to use different grafting monomers and ratio, add MMA 30g, the SBS grafting glue solution that BA 6g obtains The properties are in Table 1 below.

Embodiment 3

[0072] Produced by the method described in Example 1, SBS graft type clean smell mattress spray glue, difference is to use different grafting monomers and ratio, add MMA 33g, 2-HEMC 3g, the obtained SBS graft The branch gum properties are in Table 1 below.

[0073] Table 1

[0074]

[0075]

[0076] From these results, it can be clearly seen that the product prepared by the method of the present invention is colorless and transparent, the SBS grafting reaction is increased, a large amount of acrylic acid groups are grafted on the SBS molecular chain, and the number of double bonds in the SBS molecule is greatly reduced , so that the performance of the grafted product changes dramatically, the adhesion, bonding strength, yellowing resistance, powdering resistance, high temperature resistance are greatly improved, oil resistance, plasticizer penetration resistance, and the film is non-toxic Odorless, transparent and white, it is an ideal choice for high-end mattress manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com