Nanofiber/PVDF (polyvinylidene fluoride) compound medium with sandwich structure and preparation method of nanofiber/PVDF compound medium

A technology of polyvinylidene fluoride and nanofibers, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of low energy storage density and large dielectric loss, and achieve high dielectric constant and high The effect of breakdown field strength and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

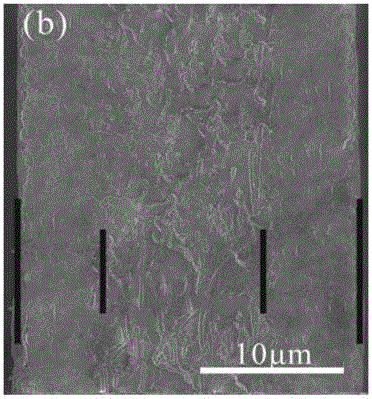

[0035] Embodiment 1: In this embodiment, a sandwich-structured nanofiber / polyvinylidene fluoride composite medium and a preparation method thereof.

[0036] A sandwich structure nanofiber / polyvinylidene fluoride composite medium, the upper and lower layers of the sandwich structure are PVDF films, the middle layer is CFO@BZT-BCT NFs / PVDF composite medium film, and the three-layer structure medium is combined by hot pressing.

[0037] A preparation method of a sandwich-structured nanofiber / polyvinylidene fluoride composite medium is as follows:

[0038] 1. Measure anhydrous ethanol and acetic acid and pour them into the beaker in turn. After stirring evenly, add acetylacetone to the above mixed solution and continue stirring until uniform. Add Ba(OH) 2 ·8H 2 O was added to the mixed solution, and after it was completely dissolved, the Ca(OH) 2 Add to the mixed solution, wait for Ca(OH) 2 After complete dissolution, the C 20 h 28 ZrO 8 Added to the mixed solution, and fina...

specific Embodiment approach 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the amount of each substance added in step one is 3.8mL absolute ethanol, 9.05mL acetic acid, 1.54mL acetylacetone, 2.17gBa(OH) 2 ·8H 2 O, 0.9gCa(OH) 2 , 0.39gC 20 h 28 ZrO 8 , 2.48mLTi(OC 4 h 9 ) 4 ; The Ti(OC 4 h 9 ) 4 After adding the mixed solution, the continuous stirring time was 30min; the PVP was added to the mixed solution, and the ratio of the mixed solution to the PVP was (14.1-14.5) mL:1g; the stirring time for the complete dissolution of the PVP was 24h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that PVP is added to the mixed solution as described in step 1, and the ratio of the mixed solution to PVP is 14.3mL:1g. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com