Universally and flexibly installed multi-position adjusting mechanism

An adjustment mechanism, multi-position technology, applied in the field of machinery, to achieve the effect of stable and smooth rotation, protection of products, and elimination of assembly gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

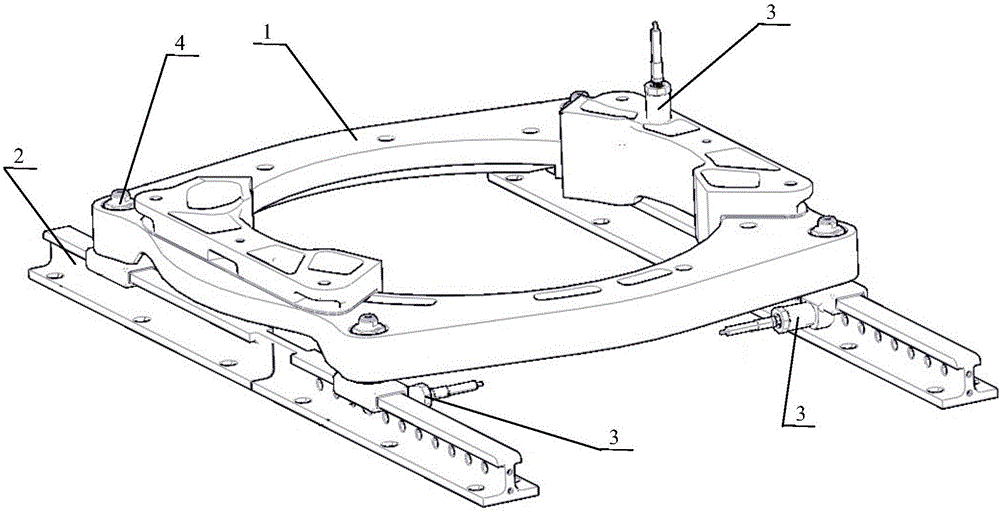

[0028] said institutions, such as figure 1 As shown, the rotating base 1 and the guide rail 2 are included, the rotating base 1 is square, and a through hole is respectively provided at the four corners of the rotating base 1, and a flexible sliding device 4 is respectively installed in each through hole, through which the flexible sliding device 4 The swivel base 1 is slidably fixed on the guide rail 2, and a seat is installed on the swivel base 1.

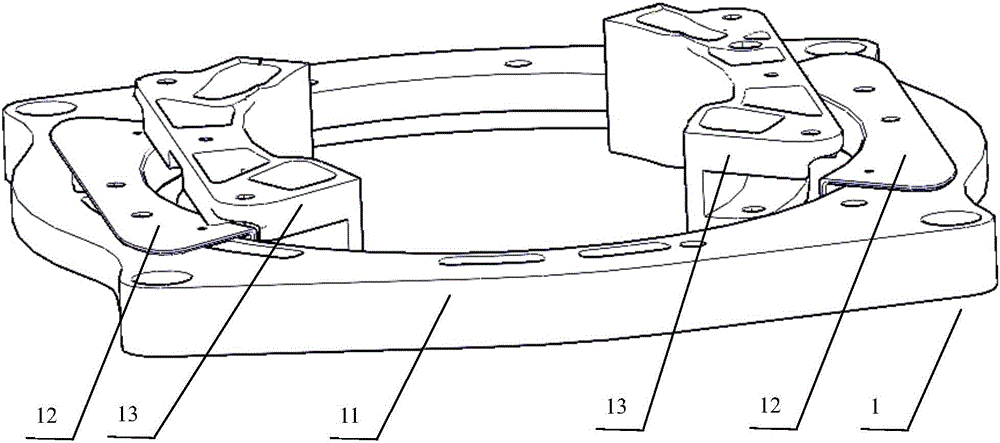

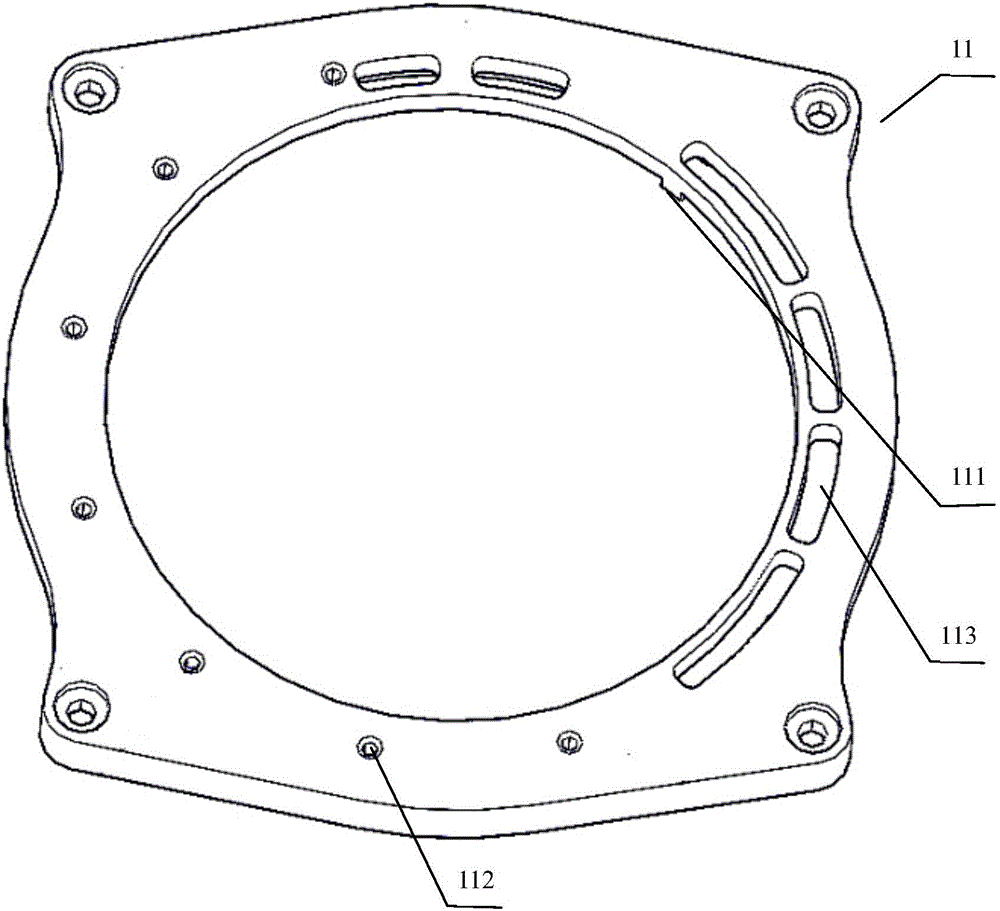

[0029] Further, such as figure 2 As shown, the swivel seat 1 includes a swivel seat body 11, which is square and has a through hole in the middle, so that the swivel seat body 11 forms a ring shape. The ring section of the swivel seat body 11 is n-shaped, and the swivel seat 1 also includes Two groove-shaped rotating blocks 13 are lined with wear-resistant sheets 12 in the grooves of the rotating blocks 13, and the rotating blocks 13 are slidably locked on the inner wall of the through hole of the rotating seat 1 through the gr...

Embodiment 2

[0042] Only the differences from Embodiment 1 will be described below.

[0043]Further, each of the first slider 45 and the second slider 46 is respectively fixed on a guide rail 2 .

[0044] When the seat is installed on two planes, the guide rails 2 are arranged in parallel, and the seat can slide along the guide rails 2 .

[0045] When the seat is installed on two planes, the guide rails 2 are non-parallel, and the seat can only be fixed and cannot slide along the guide rails 2.

[0046] When the seat is installed on three or four planes, the guide rails 2 are non-parallel, and the seat can only be fixed and cannot slide along the guide rails 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com