Guide device for hydrodynamic cleaning of lower surface of first supporting plate of secondary side of steam generator

A steam generator and hydraulic flushing technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of insufficient connection rigidity and inability to adapt to the flushing requirements of the lower surface of the first support plate of the steam generator and other problems to achieve the effect of ensuring rigidity and functional stability, and improving flushing efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

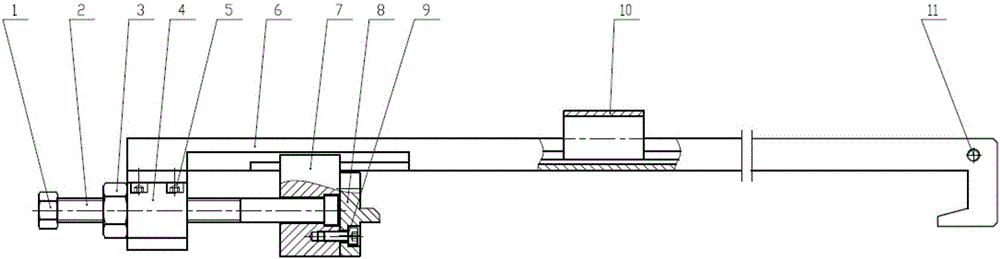

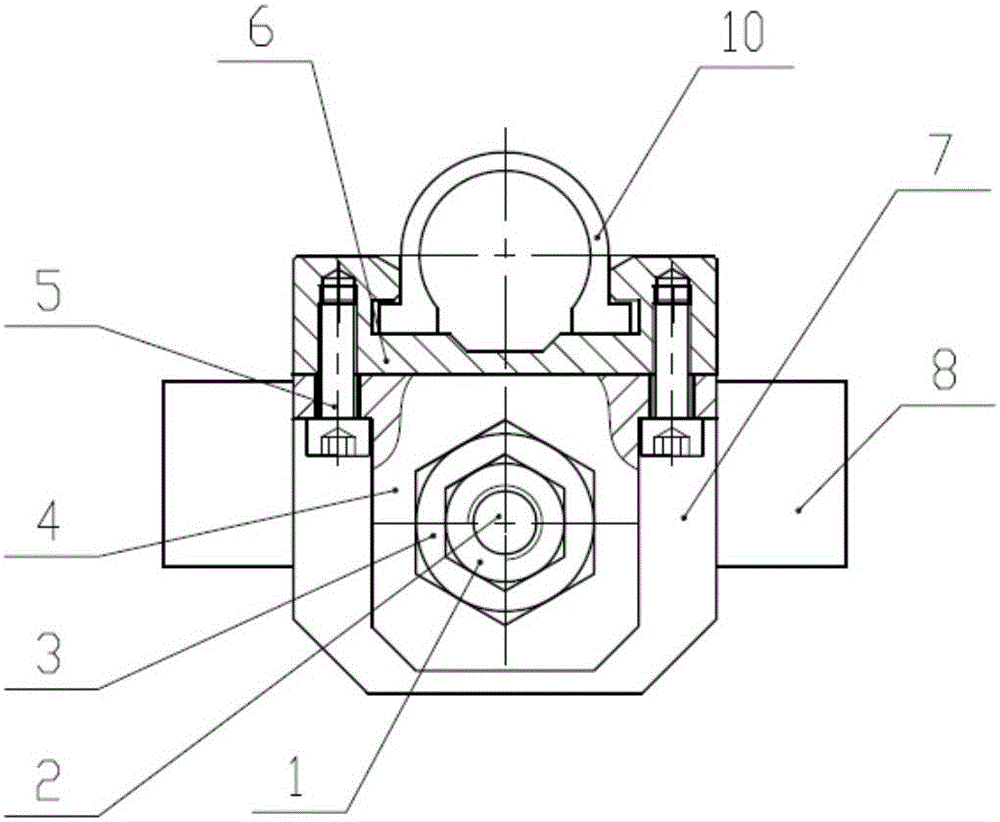

[0019] Such as figure 1 , figure 2 As shown, a hydraulic flushing guide device for the lower surface of the first support plate on the secondary side of the steam generator includes a guide rail 6, a fixed seat 4, a sliding seat 7 and a long screw 2, wherein the guide rail 6 is a grooved rail at the upper end as a whole The right front end forms a hook structure, and a limit screw 11 is set to prevent the slider 10 installed in the upper rail of the guide rail from sliding out of the guide rail 6; the left rear end of the guide rail 6 is fixedly installed with a hexagon socket screw A5 The fixed seat 4 has a threaded hole in the direction parallel to the guide rail 6; the sliding seat 7 located on the right side of the fixed seat 4 is clamped into a section of the sliding groove below the guide rail 6, on the sliding seat 7 and the center of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com