Fiber flushing spacer fluid for oilfield well cementation

A technology for flushing spacer fluid and well cementing, which is applied in the direction of drilling composition, chemical instruments and methods, etc., and can solve the problems of failure to meet the quality requirements of oil and gas reservoir cementing, low cementing quality at the two interfaces of cementing, and downhole water-sensitive intervals. Well wall collapse and other problems can be improved to improve the interface cementation environment, facilitate the cementing operation, and improve the effect of oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

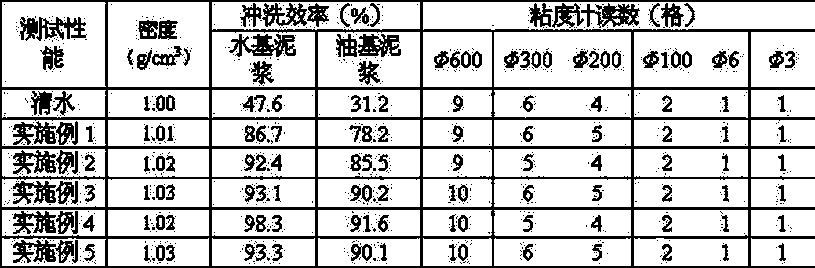

Examples

Embodiment 1

[0014] The raw material components and weight contents of the fiber flushing spacer fluid for oilfield well cementing of the present invention are as follows: 100 parts of base fluid, 0.2 part of anti-cracking fiber and 0.4 part of sodium petroleum sulfonate. The raw material components and weight contents of the base liquid are as follows: 92.5 parts of clear water, 1.0 part of water glass and 0.1 part of hydroxyethyl cellulose. The crack-resistant fiber is 6mm long polypropylene fiber; the crack-resistant fiber is 2mm long medium-alkali glass fiber. The water glass is liquid sodium silicate, wherein the mass percentage of sodium silicate is 40%, and the water glass modulus is 2.2.

Embodiment 2

[0016] The raw material components and weight contents of the fiber flushing spacer fluid for oilfield well cementing of the present invention are as follows: 100 parts of base fluid, 0.3 part of anti-cracking fiber and 0.7 part of sodium petroleum sulfonate. The raw material components and weight contents of the base liquid are as follows: 92.5 parts of clear water, 3.0 parts of water glass and 0.3 parts of hydroxyethyl cellulose. The crack-resistant fiber is 7mm long polypropylene fiber; the crack-resistant fiber is 3mm long medium-alkali glass fiber. The water glass is liquid sodium silicate, wherein the mass percentage of sodium silicate is 44%, and the water glass modulus is 2.4.

Embodiment 3

[0018] The raw material components and weight contents of the fiber flushing spacer fluid for oil field cementing of the present invention are as follows: 100 parts of base fluid, 0.4 parts of anti-cracking fiber and 1.0 part of sodium petroleum sulfonate. The raw material components and weight contents of the base liquid are as follows: 92.5 parts of clear water, 5.0 parts of water glass and 0.5 part of hydroxyethyl cellulose. The crack-resistant fiber is 8mm long polypropylene fiber; the crack-resistant fiber is 4mm long medium-alkali glass fiber. The water glass is liquid sodium silicate, wherein the mass percentage of sodium silicate is 48%, and the water glass modulus is 2.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com