Frequency selective surface structure

A technology of frequency selective surface and structural unit, applied in the field of communication, can solve the problems of non-selective frequency of shielding, failure to achieve miniaturization, and large size of frequency selective surface structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

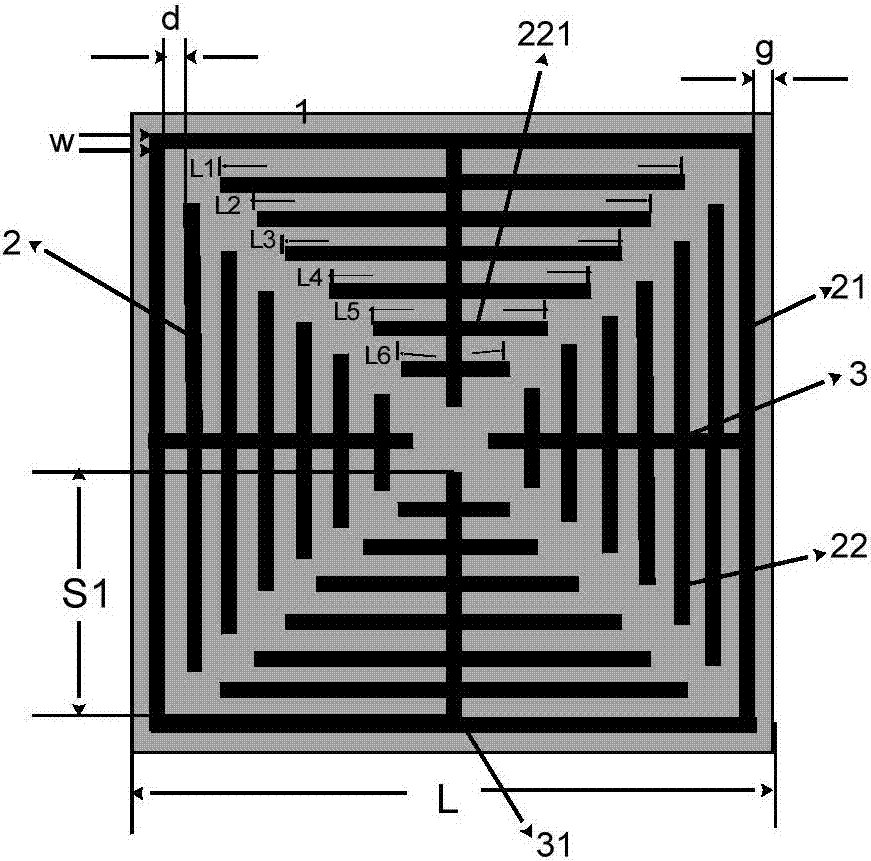

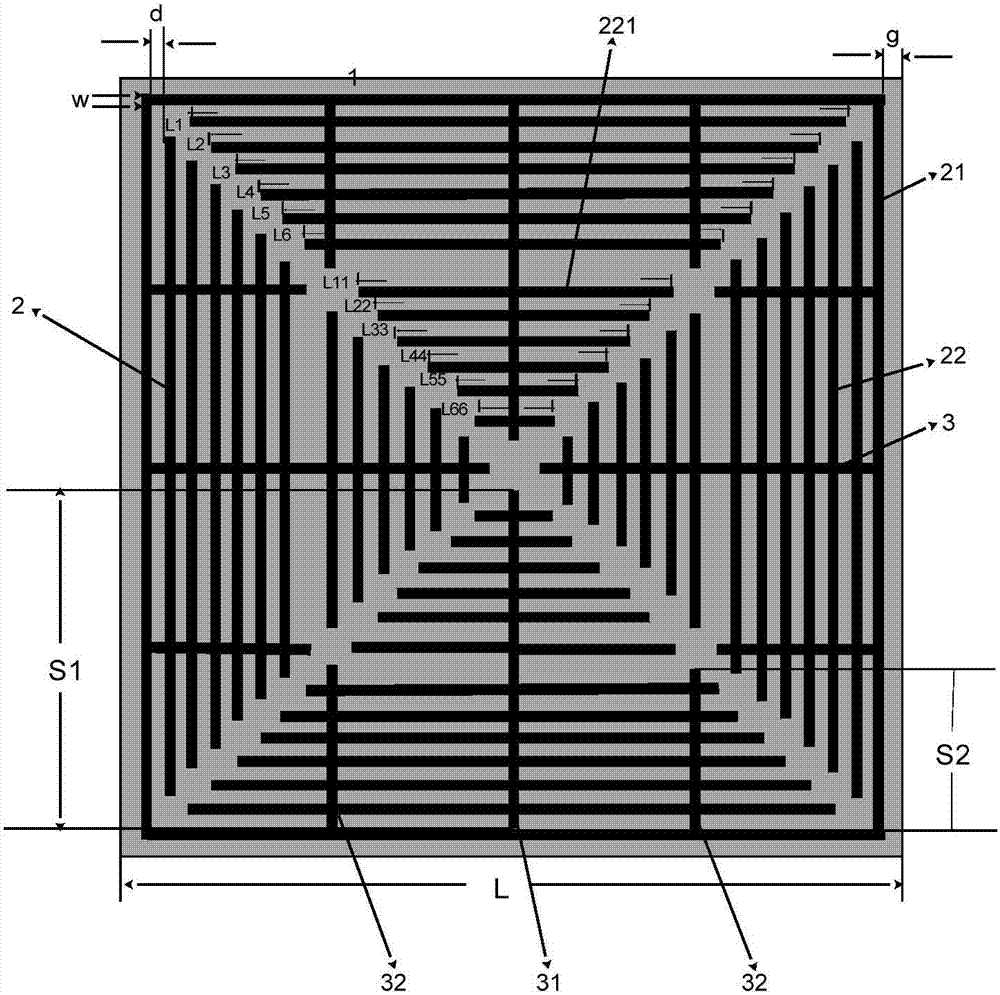

[0044] In the frequency selective surface structure unit, a dielectric substrate with a thickness of 1 mm, a dielectric constant of 4.3, and a tangent loss of 0.025 is used. Formed on the dielectric substrate in the form of metal patches such as figure 2 In the structure shown, the number n of square rings in the slit square ring array is 12, wherein 6 slit square rings intersect with the first metal strip 31 and the second metal strip 32 at the same time, and their lengths are L1, L2, L3 respectively , L4, L5, L6, the 6 square rings do not intersect with the second metal strip 32, but only intersect with the first metal strip 31, and their lengths are respectively L11, L22, L33, L44, L55, L66, specifically:

[0045] A square ring structure and a closed square ring metal wire are arranged on the mechanism plane of the dielectric substrate. The side length of the closed square ring metal wire is L=8.7mm, and there is a square ring array of gaps inside the closed square ring me...

Embodiment 2

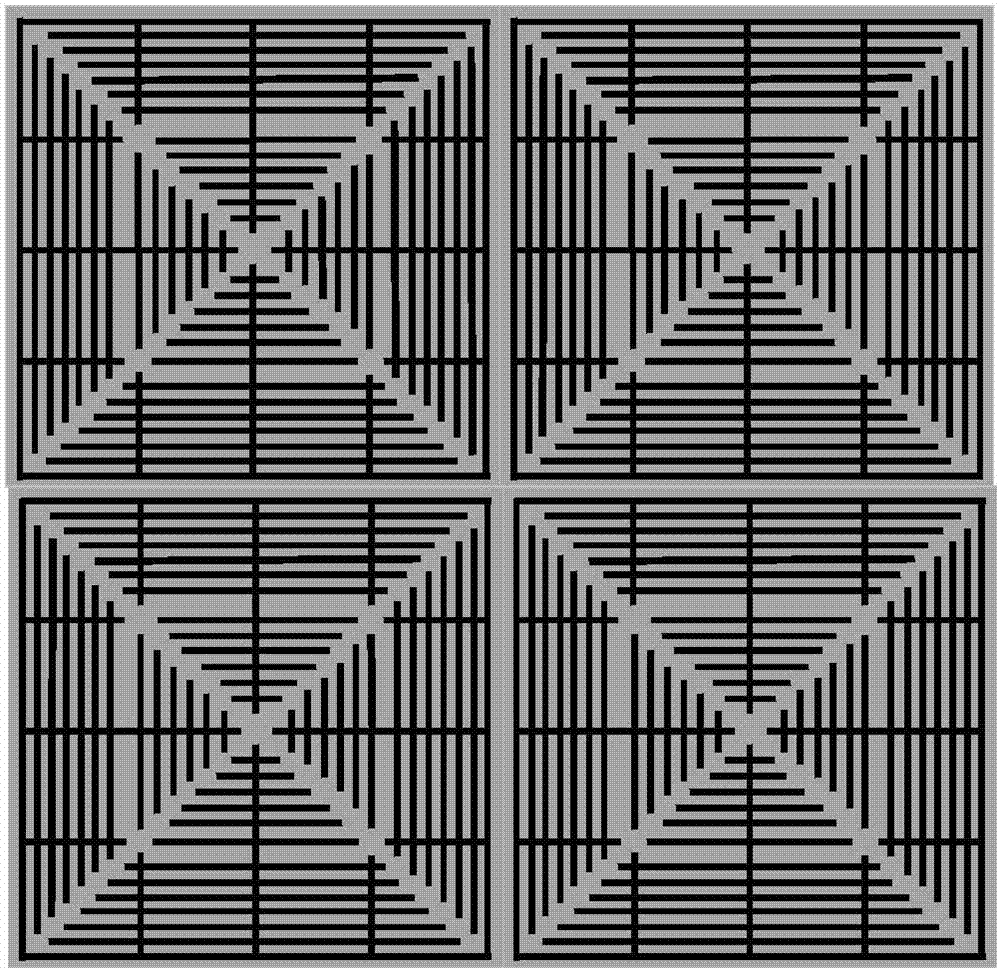

[0056] The frequency selective surface structure unit provided by the embodiment of the present invention and the frequency selective surface structure composed thereof are versatile, and the resonant length is increased by further reducing the distance d between the metal lines and the width w of the metal strip, thereby reducing the resonant frequency ; It is also possible to increase the resonant frequency by appropriately increasing the distance d between the metal lines and the width w of the metal strip, so as to achieve the effect of filtering out electromagnetic waves of a certain frequency.

[0057] This example is to increase the spacing d between the metal lines and the width w of the metal strips and change the unit size L to reduce the resonance wavelength to filter out electromagnetic waves with a frequency of 5.1GHz. The thickness is 1mm, the dielectric constant is 4.3, and the tangent loss is 0.025 dielectric substrate, the number of square rings in the slit squ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com