La-Mn compound oxygen reduction catalyst material and preparation method thereof

A technology of catalyst and mixed solution, which is applied in the field of La-Mn composite oxygen reduction catalyst material and its preparation, can solve the problems that no La-Mn composite oxide catalyst material has been found, it is difficult to meet the practical application of metal-air batteries, and the activity is low. Achieve the effects of improving electrochemical stability, high use value, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

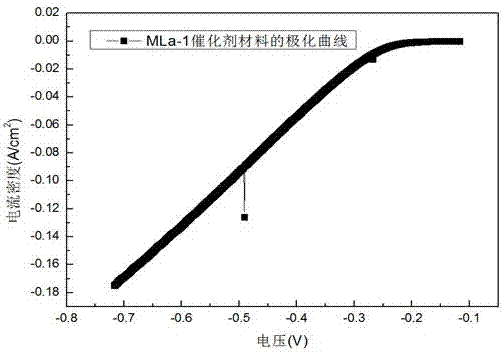

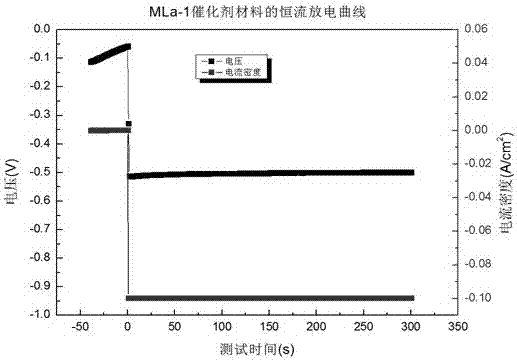

[0014] Example 1 First, 0.035 mol of potassium permanganate was dissolved in deionized water to form solution 1; then 0.07 mol of lanthanum nitrate was dissolved in deionized water and 0.1 mol of manganese nitrate solution (50% by mass) was mixed to form a mixed solution 2 ; Then, under stirring conditions, slowly add mixed solution 2 to solution 1 to form mixed solution 3; finally use KOH solution to adjust the pH value of mixed solution 3 to 10, and place it in a 60℃ constant temperature water bath for constant stirring; suction filtration and washing After 5 times, it was dried in a vacuum oven at 100°C, and then placed in a high-temperature furnace for sintering at 400°C for 5 hours to obtain a La-Mn composite oxygen reduction catalyst material MLa-1.

Embodiment 2

[0016] First dissolve 0.054mol potassium permanganate in deionized water to form solution 1; then dissolve 0.017mol lanthanum nitrate in deionized water and 0.1mol manganese nitrate solution (50% mass fraction) to make mixed solution 2; Under stirring conditions, mixed solution 2 was slowly added to solution 1 to form mixed solution 3; finally, the pH value of mixed solution 3 was adjusted to 11 with KOH solution, and placed in a constant temperature water bath at 70℃ for constant stirring; after suction filtration and washing 4 times It was dried in a vacuum oven at 120°C, and then placed in a high-temperature furnace for sintering at 550°C for 4 hours to obtain a La-Mn composite oxygen reduction catalyst material.

Embodiment 3

[0018] First dissolve 0.072mol potassium permanganate in deionized water to form solution 1; then dissolve 0.035mol lanthanum nitrate in deionized water and 0.107mol manganese nitrate solution (50% mass fraction) to make mixed solution 2; Under stirring conditions, mixed solution 2 was slowly added to solution 1 to form mixed solution 3; finally, the pH value of mixed solution 3 was adjusted to 12 with KOH solution, and placed in a constant temperature water bath at 80℃ for constant stirring; after suction filtration and washing 6 times It was dried in a vacuum oven at 90°C, and then placed in a high-temperature furnace for sintering at 750°C for 3 hours to obtain a La-Mn composite oxygen reduction catalyst material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com